Viscosity - the resistance of a fluid to shear or tensile stress - is an important measurement in fluid analysis. Viscosity can be thought of as resistance to flow, with highly viscous fluids being more resistant to flow. Understanding the role of viscosity and measuring it is key to the proper analysis of many engineering situations. For example, using lubricating fluids that become more viscous at high temperatures can be disastrous in a car engine. Therefore, sometimes it is important to be able to measure viscosity. Engineers can do this by using viscosity measurement equipment. Commonly used devices are viscometers and rheometers. This article explains the differences between the two devices and when to use each.

Viscometer

In most cases, viscometers are used to measure viscosity. They are suitable for fluids whose viscosity does not change under different flow conditions; when the viscosity changes with the flow conditions, a rheometer is required. Viscometers generally work by comparing a stationary object with a fluid flowing, and vice versa. Thus, the viscometer can be placed in a fluid stream or moved through a stationary fluid. The flow needs to have a Reynolds number in the laminar region in order to record accurate values. The measure of resistance is obtained by measuring the resistance during relative motion through the fluid. There are several types of viscometers available, some used in laboratories and others used as portable viscosity Testers.

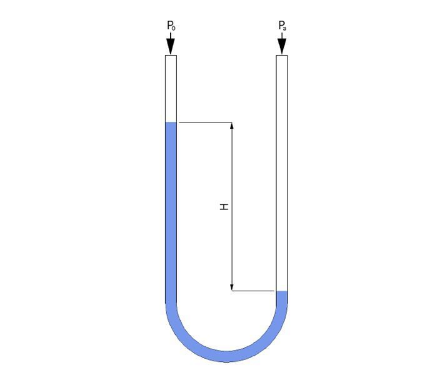

U-tube viscometer

These viscometers are commonly used in laboratory environments. The user can obtain dynamic viscosity by measuring the time it takes a fluid to flow between two points on a capillary of known radius. It is necessary to know the density of the fluid to calculate the viscosity in this way.

Falling Ball Viscometer

As the name suggests, these viscometers use a falling ball to measure viscosity. Measuring the time it takes for a falling sphere (with known density and radius) to travel between two markers, the user can then calculate viscosity. This model is also commonly used in laboratories. They study principles derived from Stokes' law, which imparts drag on a sphere.

Falling Piston Viscometer

Falling piston viscometers operate on a similar principle to falling ball viscometers, except that they measure the resistance of the piston to flow through the liquid. These devices are extremely durable and easy to operate, requiring little maintenance. Therefore, they are very popular in industry.

Rotational Viscometer

A Rotational Viscometer measures a fluid's resistance to torque. There are several types of Rotational Viscometers: the Stabinger viscometer was developed in 2000, and the Stormer viscometer is commonly used to measure the viscosity of coatings. Stabinger viscometers use the proprietary Krebs unit (KU).

Foam Viscometer

Bubble viscometers measure the time it takes for bubbles to rise through a liquid. These viscometers are often used with resins or varnishes. These viscometers are fast and very useful for measuring viscosity in the field. Stokes' viscosity is measured using a model of the letter comparison method, which is equal to 1 cm 2 s -1 .

Rheometer

Rheometers are useful for non-Newtonian fluids; that is, fluids whose viscosity is not described by a single value. Greater force generally induces greater viscosity in non-Newtonian fluids. There are several commercial rheometers on the market. For forces below 10 Pa, ThermoFisher's CaBER is popular. Cambridge Polymers Group's FiSer is available for values from 1 to 1000 Pa, while the Gottfert Rheotens is rated above 100 Pa and the Xpansion Instruments Sentmanat extensional rheometer is rated over 10 kPa.

Why Measure Viscosity

Engineers may wish to measure viscosity in any application involving fluid flow, especially in design. Because viscosity changes dramatically with temperature, it is important to understand what happens to lubricants when exposed to high temperature, high pressure, or low temperature. Failure to do so may result in design errors. Engineers developing new lubricants or other fluids may also wish to measure the viscosity of a fluid in a laboratory setting.

Field engineers may also need to measure viscosity. They can do this with any of a number of portable viscosity Testers or larger industrial models. Viscosity is important in many commercial applications, such as consumer products such as shampoo, and viscometers are widely used for quality control.