1. Function:

SNB series and DV series digital viscosity measuring instruments are used together , and are specially used to accurately measure the viscosity of high-temperature liquids such as hot melt adhesives, paraffin wax, asphalt, medicines, high polymers, and food. Intelligent temperature controller ( programmable intelligent temperature controller is optional), precisely controls the temperature of the heater, can be equipped with a disposable measuring cylinder, can be equipped with a standard SC4 rotor, and is easy to operate.

2. Operation steps:

2.1 Before using the temperature-controlled heater to measure the viscosity of the sample, please carefully read the "Instructions for Use of Temperature-Controlled Heaters" and " Instructions for Use of SNB Series and DV Series Digital Viscometers ";

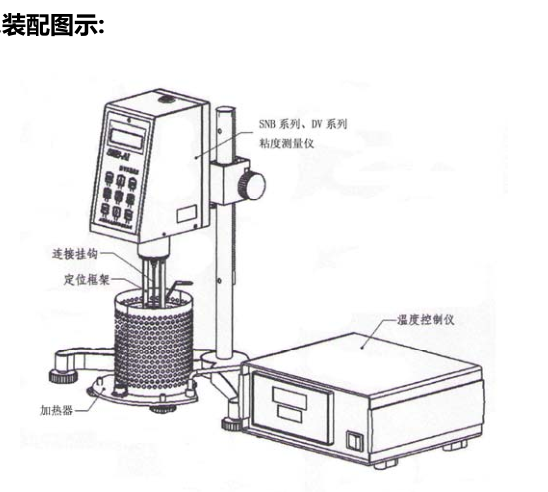

2.2 Place according to the 4. position of the assembly diagram, connect the viscosity measuring instrument and the temperature control heater ;

2.3 Use special tweezers to take out the graduated cylinder from the heater, clean it and put it back the heater positioning slot;

2.4 Install the positioning frame on the viscosity measuring instrument (screw to the right to install, turn to the left to remove), screw the selected rotor and connecting hook into the connecting screw (screw to the left to install, turn to the right to remove) );

2.5 Adjust the lifting frame knob of the viscosity measuring instrument so that the viscosity measuring main engine slowly and gradually descends. After confirming the position of the positioning frame, add the experimental sample, and at the same time ensure that the liquid level of the sample is equal to the liquid level mark of the rotor, and cover the insulation cover to adjust the viscosity. The position of the measuring instrument and the heater is level, and the base of the heater is moved so that the connecting hook should be in the middle of the small hole of the heat cover, so as to ensure that the rotor cannot touch the measuring cylinder and the heat preservation cover;

2.6 Turn on the switch after the temperature controller is powered on, and the temperature change process in the whole experiment can be controlled by inputting the temperature value;

2.7 Turn on the power switch of the viscometer, and input the selected rotor number, such as No. 27;

2.8 Select the rotating speed. Generally, the rotating speed is 6 rpm when starting up, and the user can adjust the rotor rotating speed according to the needs;

2.9 Press the measurement key to simultaneously measure the viscosity value and percent scale at the current rotor and speed;

2.10 During the measurement process, it should be noted that the sample should be sufficiently kept at the test temperature to keep the indication value stable and accurate. The tested sample should have enough holding time to make the sample reach the equilibrium temperature required for the test;

2.11 After the measurement work is completed, first turn off the machine, then remove the heat preservation cover, and slowly adjust the viscosity measuring instrument up. Move the entire rotor away from the sample, wait a while to remove the rotor for cleaning;

2.12 Observe whether the temperature controller has been set below room temperature, if not, please set it below room temperature and shut down;

2.13 Use special tweezers to take out the measuring cylinder from the heater and clean it, and pay attention to prevent burns during cleaning the rotor and measuring cylinder;

2.14 Put the cleaned measuring cylinder back into the heater. If the cleaned rotor is not in use, please do not screw it into the connecting screw, and put it aside.

3. Doing the following points will help to measure more accurate values:

3.1 In order to ensure that the liquid level of the sample to be tested is level with the liquid level mark of the rotor, water can be used to quantitatively estimate the sample amount (volume) required for the experiment or convert the weight into volume;

3.1.1 Take out the graduated cylinder from the heater with special tweezers, fill it with water and put the graduated cylinder back into the heater;

3.1.2 Install the positioning frame on the viscosity measuring instrument (screw right to install it, turn left to remove it), and screw the selected rotor and connecting hook into the connecting screw (screw it to the left to install it, and turn it to the right to remove it) remove);

3.1.3 Adjust the lifting frame knob of the viscosity measuring instrument so that the main body of the viscosity measuring instrument is slowly and gradually lowered, and the rotor is gradually immersed in the liquid to be measured. Confirm the position of the positioning frame. ;

3.1.4 Pour water into a graduated measuring cup to determine the amount of ;

3.2 Accurately control the temperature of the measured liquid;

3.3 Immerse the rotor in the liquid to be measured for a long enough time to make the temperature of the two consistent;

3.4 Maintain the uniformity of the sample liquid;

3.5 When measuring, place the rotor in the center of the container, and be sure to install the rotor positioning frame;

3.6 Ensure the cleanliness and shaking of the rotor;

3.7 When the high speed measurement immediately changes to low speed, the machine should be turned off, or the measurement time at low speed should be a little longer, so as to overcome the error caused ;

3.8 When the viscosity is measured at low speed, the measurement time is relatively longer;

3.9 During the measurement process, due to the need to change the rotor and the liquid to be measured, after changing the position of the viscosity measuring instrument by rotating the lifting chuck, check and adjust the horizontal position of the viscosity .