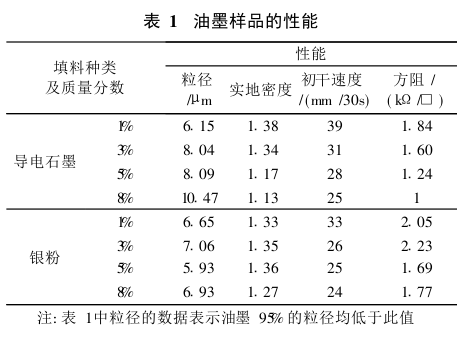

In the experiment of the influence of conductive filler on the performance of conductive ink for electrothermal film, the influence of conductive filler on particle size needs to be tested for the fineness of the conductive ink sample with a fineness plate.

Particle size refers to the size of a single particle as an object, which determines the nature and efficiency of the particle processing process to a large extent , and is the basic basis for selecting and evaluating the preparation method, process and process control . Ink is a typical dispersion system . The particle size of ink is the pigment (including filler) aggregate as the object to represent the dispersion state of pigment particles in the ink system, and the particle size reflects the dispersion of pigment particles in ink. Fig. 1 is the relationship curve between the addition amount of conductive filler (conductive graphite and silver powder) in ink and the particle diameter of ink sample.

It can be seen from Figure 1 that when conductive graphite is added, the particle size increases with the increase of the amount added; when silver powder is added, the overall particle size of the ink does not change much, and when the mass fraction of silver powder is 5%, the particle size is 5.93μm, reaching the lowest value. The dispersibility of solid particles in the ink system is related to the wettability of the binder to the solid particles. Graphite belongs to a layered structure and is relatively difficult to wet. Therefore, when conductive graphite is added to the ink system, with the addition of conductive graphite The layered structure of graphite causes the graphite particles to form a scaly structure and aggregate with each other, which reduces their dispersion in the binder and increases . When silver powder is added, because silver powder mostly exists , silver powder oxides are amphoteric oxides. Compared with graphite, they have better affinity with the binder, so their dispersibility is better than that of graphite systems . Generally speaking, the grinding and dispersing process can only break and wet the aggregates , but cannot break it to a size smaller than the original particle size of the pigment and the final particle size, which is related to the formulation components of the system, grinding and dispersing It is related to the process conditions and the use of additives.

Fig.1 Relationship between ink particle size and filler mass fraction