The adhesion of the coating film refers to the firmness of the combination of the coating film and the surface of the coated object. The force is one of the important indicators of the physical and mechanical properties of the coating. Through the inspection of this item, it can be checked whether the composition of the coating, especially the use of resin, is reasonable. . The adhesion of the coating film not only depends on the selected coating base material, but also has a very important relationship with the surface pretreatment of the substrate, the construction method and the maintenance of the coating film. Surface coating, the adhesion is poor.

There are several methods for measuring the adhesion: the circle method, the scratch (or scratch) method, the pull-off method and the twist-off method. method, while GB9286-88 stipulates the method of measuring adhesion by cross-hatch method ; GB5210-85 stipulates the method of measuring coating adhesion by pull-off method.

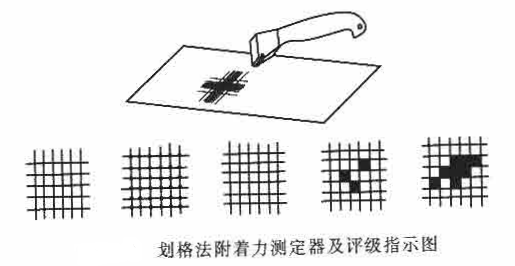

This article mainly introduces the cross-hatch method, which uses a paint cross-hatch to test the adhesion of the coating film.

The cross-cut method is carried out in accordance with GB926-88. The experimental tool is a cross-cut Tester, also known as a paint film cross-cut device, which is a multi-blade cutter with 6 cutting surfaces, made of high-alloy steel, and the cutting knife is spaced at 1m to apply the sample on the sample board and wait for it to dry After penetration, pull 3~4cm in parallel with a cross-cut Tester, there are six cut marks, which should cut through the coating film; then use the same method to be perpendicular to the former, make six cut marks; thus many small squares are formed. Use a soft brush to brush 5 times from the diagonal direction or stick it on the grid with tape and pull it away quickly, check the cut surface of the test coating with a 4 times magnifying glass, and compare it with the instructions and drawings (see Figure 3-16 ), the cutting edge is completely smooth, and no grid falls off is grade 0; the coating has a little flake separation at the intersection of the cut, but the cross-cut area is obviously affected by no more than 5% is grade 1; the edge of the cut or the intersection is coated The layer peeling off is obviously greater than 5%, but the impact is not more than 15% is grade 2; the coating part or all falls off in the form of large fragments along the edge and between 15% and 35% is grade 3: by analogy, grade 0 If the strength is very good, it is generally considered that the adhesion cannot meet the requirements in anti-corrosion coatings if it exceeds level 2.