Temperature measuring paper is commonly known as temperature patch, temperature sticker, temperature label, temperature patch, temperature label, etc. It is a self-adhesive adhesive on the back, which can be pasted directly to the place where the temperature is measured. When the temperature of the pasted place is higher than the discoloration temperature, it will automatically change from the original white to black after overheating. After overheating and discoloration, it will remain black forever, indicating that the place has been The set temperature has been exceeded.

Temperature measuring paper and temperature labels are widely used in electrical connectors, transformer busbar connectors, electrical switch contacts, motors, bearings, etc. For daily inspection, you only need to check whether each patch has changed color, and you can complete the complicated and time-consuming temperature measurement work, which makes up for the shortcomings of infrared thermometers and contact point thermometers.

Of course, temperature paper can also be used for temperature marking, such as whether the disinfection and sterilization temperature has reached, whether the baking temperature has reached the preset temperature, whether the temperature of the material during transportation exceeds the allowable temperature mark, etc. It can be used in occasions where you want to know whether the temperature exceeds or does not exceed.

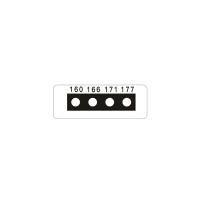

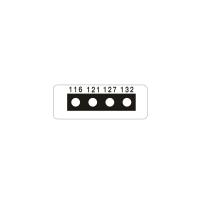

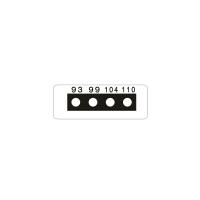

The discoloration temperature points of the thermometer paper are: 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 100, 110, 120, 140, 150, 165°C. There are two kinds of specifications: single-point and multi-point combination. Single-point means that there is only one temperature on one patch. A little more combined type means that there are multiple external temperatures on one patch and combined together.

The temperature measuring wax sheet is an early product used to indicate the overheating temperature of electrical joints. It is well known by the majority of electric workers. The temperature measuring wax sheet is made according to the melting point principle of temperature wax. When the temperature measuring wax sheet exceeds the rated melting temperature, it will automatically melt and fall off. Indicates overheating. Temperature-measuring wax sheets have been used for a long time and are widely used for overheating temperature indication of electrical joints in substations. There are five temperatures: 60°C (yellow), 70°C (green), 80°C (red), 90°C (caramel), and 100°C (blue).

502 glue is needed to assist the paste when pasting the temperature measuring wax sheet, and it does not have glue itself.

The difference between temperature measuring paper and temperature measuring wax sheet

From the above introduction, readers should have a preliminary understanding of the basic differences between temperature measuring paper and temperature measuring wax sheet, the specific list is as follows:

| Name | paste | overheating state | Application range | other |

| thermometer paper | The back itself has adhesive glue, which can be pasted directly, convenient and firm. It is in the same position before and after overheating, which is easy to judge. | Turns from white to black when overheated. Advantages: The color contrast is large, and the color change is eye-catching. Once overheated, keep it for a long time, and check it later when it is convenient. | The application industry is wider. It can be pasted on curved surfaces, such as wrapping directly on the cable joint to monitor the overheating of the cable head, etc. | Wide range of applications: such as electrical connectors, disinfection and sterilization temperature marking, clothing adhesive lining, dyeing and finishing temperature marking, etc. |

| Temperature measuring wax | Need to apply 502 glue on the bottom surface, it is troublesome to paste. | Melts when overheated. Disadvantages: The wax that melts and flows down sometimes falls to the contacts such as the relay below, causing secondary failures. It is easy to be affected by aging, vibration, etc. to fall off abnormally, resulting in misjudgment, because after the abnormal fall off, it is not known whether it was pasted at that time. | Pasting on curved surfaces is not possible. Single application. | Most of them are only used for overheating temperature indication of electrical connectors. |