Ball mill selection

Ball mill size selection: There are 4 ball mill jars on the planetary disk of the planetary ball mill, and the size of each ball mill jar is 1/4 of the total volume of the planetary ball mill. For example, a 4L planetary ball mill is equipped with 4 ball mill jars of 1L size. If it is equipped with a vacuum tank, due to the characteristics of the vacuum tank, the outer dimension of the tank with the same volume is one model larger. For example: a vacuum tank with a total volume of 2L (that is, 4 pieces of 0.5L) needs to be equipped with a planetary ball mill with a total volume of 4L.

Selection of planetary ball mill size

According to the amount of material to be ground, choose the size of the planetary ball mill.

A=C/ρ*3. Calculation formula for planetary ball mill size selection:

A is the size of the planetary ball mill (unit: L), C is the mass of the primary grinding material (unit: kg), and ρ is the bulk density of the grinding material (unit: kg/L).

illustrate:

Grind 2Kg of material at a time, and the bulk density of the material is 1.5Kg/L, then choose the size of the planetary ball mill A=2/1.5*3=4L, that is, choose a planet with a size of 4L

For example:

Ball mill, one-time grinding materials such as XQM-4L

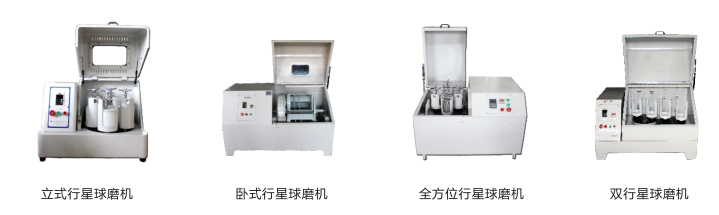

Selection of planetary ball mill style and special function configuration:

Planetary ball mills are divided into four styles: vertical, horizontal, comprehensive, and double planetary. The corresponding style can be selected according to the grinding requirements of the material. The products of each style can be equipped with air cooling or heating equipment according to the temperature requirements

Planetary ball mill style and special function configuration selection reference table:

| Planetary ball mill model selection | Grinding material properties |

| Vertical planetary ball mill | General material grinding, no special requirements |

| Omni-directional planetary ball mill or horizontal planetary ball mill | The material is easy to sink and harden |

| Double planetary ball mill | Requires ultra-high speed, ultra-fine grinding |

| With air cooling device or liquid nitrogen device | The grinding process heats up and needs to be cooled |

| Equipped with vacuum ball mill tank | Easy to oxidize, need vacuum environment or atmosphere protection |

| with heating | Grinding under high temperature conditions is required |

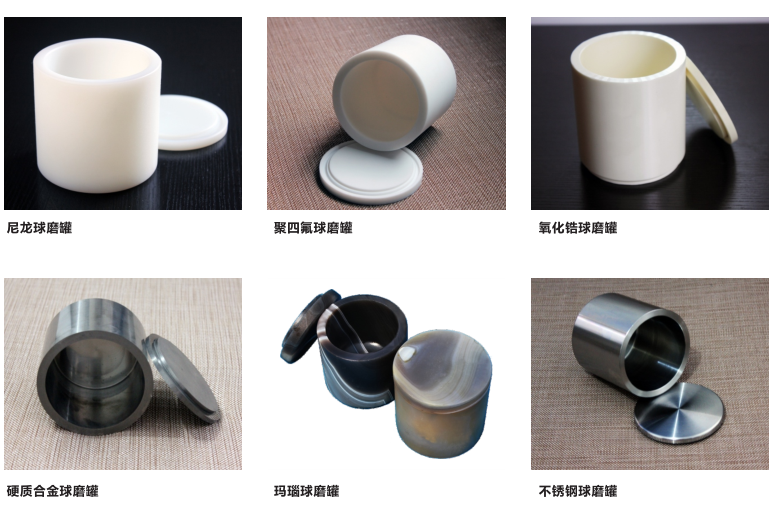

Ball mill material selection

| Types and requirements of grinding materials | Ball mill material selection reference |

| Soil and materials that are not allowed to bring in impurities | Agate ball mill jar |

| Materials that are not allowed to bring impurities into metals and non-metals | Zirconia ball mill jar |

| High hardness materials such as diamond and cemented carbide | Carbide Milling Jar |

| Strong acids, strong alkalis and high temperature conditions, etc. | PTFE ball mill tank |

| Iron and steel minerals, materials with low impurity sensitivity | 304 stainless steel ball mill tank |

| Pigments, post-sequence high temperature processable materials | Nylon ball mill jar |

| Aluminum-containing materials such as ceramic glazes | Corundum ball mill jar |

| Lithium batteries and other electronic materials | Polyurethane ball mill tank |

| Materials that are easy to oxidize and require special atmosphere protection | Vacuum milling tank |