During the coating, drying or curing process, blockage often occurs, hiding air or solvent, and forming holes or bubbles in the coating film; when the coating dries, the air or agent migration causes pinholes and bubbles. Irregularity and unevenness on the surface of the object to be coated can also cause small spots or holes in the coating film: physical damage after coating, such as scratches, etc.; these are the causes of missing coating. When leak coating exists, corrosive media such as oil, water, acid, gas, etc. penetrate into the interior of the coating or even the substrate through pinholes or holes, causing the coating to lose its shielding effect, causing filiform corrosion to weaken the surrounding protective layer. If it is not repaired in time, these areas will become localized corrosion and accelerate the corrosion process, causing the coating to fall off repeatedly. For the coated objects in a severe corrosive environment , such as workpieces that are continuously immersed in corrosive solutions, it is extremely important to check their pan coating, pinholes and holes. It is necessary to find loopholes in time and remedy them in time to ensure the coating quality

Inspection instrument: For most non-conductive coatings with a total dry film thickness of less than 20mal (508μm), a low voltage-wet sponge full-coat inspection instrument is required; for non-conductive coatings with a total dry film thickness of 20mil (508gm) Coatings or insulating coatings need to use a high-voltage leak Detector a spark leak Detector. Both work on the same principle. The instrument is in direct or indirect contact with the substrate. When the electrode moves across the coating surface, the Any discontinuity in the circuit will allow the current to flow to the substrate to form a path. At this time, the instrument will send out an acoustic signal, and an electric spark will appear at high voltage.

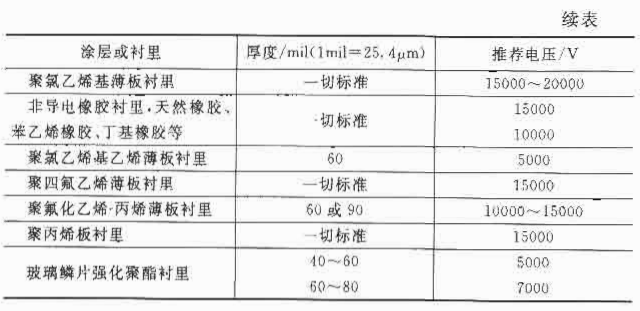

When signaled, observe the coating and mark it with oil-free chalk for repair and re-inspection. See table for guidelines on holiday check voltage recommendations.

If the design specification requires a pinhole-free coating or lining, first ensure that the coating or lining is fully dry before checking for leaks or pinholes , because the solvent left in the coating film will affect the conductivity of the coating or lining However, a leak inspection test should be scheduled prior to the recoating deadline to ensure satisfactory adhesion of any repaired layers. The test voltage should be in accordance with the above table . When the voltage is adjusted too high, void defects may burn through the coating or lining to reach metal substrate, so that it is necessary to expand the repair coating or village; if the repair is neglected, local corrosion will be formed and the corrosion process will be accelerated. . In order to avoid this situation, it is necessary to select an appropriate voltage for the test. Generally , a low-voltage leak Tester is used for the leak detection test of the coating film with a dry film thickness below 500m.

When checking out the paint leak in the coating or tree, use oil-free chalk to mark the leak paint area. If there are several missing coating areas on a total area, the entire area should be circled. The missing coating area should be repaired , and the large area of missing coating area should be painted again to meet the technical specifications and factory instructions. After the repair layer is fully cured, the missing coating inspection should be carried out again. In the case , the coating or lining should be removed and recoated.

It should be noted that for different types of coatings, the voltage used should be based on empirical values, and may be appropriately different. Especially for one-component solvent , it takes two weeks or longer for them to completely dry to form a hard coating film , which is different from two-component curing coatings such as epoxy , The leak detection test is generally arranged to be carried out within a period of time after the completion of the entire project. In order to test the potential resistance performance use high-voltage spark leak detection on the thicker coating. Although it can be applied, it often causes the breakdown of the coating and greatly destroys the protective performance of the coating. , not advisable.