For many in the healthcare industry, BMR is an acronym for Basal Metabolic Rate. If you thought this was a health science article about expending energy, we're disappointed. Instead, this article is about a different kind of BMR: metal-based reading. We'll describe what it is, what it means, how to get it, and how it affects coating thickness.

Coating Thickness Standard Introduction

There are two common industry-standard standard practices governing the measurement of dry film thickness of coatings on metallic substrates, including ASTM D7091, applicable to ferrous metals and non-magnetic, non-conductive coatings and non-magnetic coatings applicable to non-ferrous metals Nondestructive Measurement of Dry Film Thickness and SSPC-PA 2, Procedure for Determining Compliance with Dry Coating Thickness Requirements. Both address the use of Type 1 (magnetic pull-down) and Type 2 (electronic) gauges and BMR acquisition. SSPC-PA 2 also addresses the frequency of measurements and the acceptability of measurements.

What are BMRs?

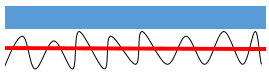

BMR is the effect of substrate roughness on a coating Thickness Gauge. Roughness is produced by preparing the substrate (such as blast cleaning or power tool cleaning), resulting in a surface texture or "profile", or by a manufacturing process that imparts roughness to the substrate. The instrument that measures the dry film thickness of the applied coating goes part way down into the rough metal surface in order for it to work properly (shown by the red line). However, the specification lists the required coating thickness as measured from the top of the peak of the surface profile (shown by the blue bar graph). This inherent amount of variation is known as the metal substrate effect. It is subtracted from the coating thickness measurement to remove any effect of surface roughness. If BMR is ignored,

Alternatively, for Type 2 gauges, one or more measured shims (one shim is considered a one-point adjustment, while two shims spanning the intended range of use are considered a two-point adjustment) can be placed on the ready on the product. The (rough) metal surface and gauges are adjusted to correspond to the shim thickness, effectively eliminating any need to measure and deduct BMR. Under SSPC-PA 2, these measured shims are not permitted for use with Type 1 gages unless expressly permitted by the gage manufacturer, so in most cases a BMR is required when using Type 1 gages.

Taking Metal Base Readings

Section 6.2 in SSPC-PA 2 states: "To compensate for any effects of the substrate itself and surface roughness, take measurements from the bare, prepared substrate at at least ten locations (arbitrarily spaced) and Calculate the average. This average is the metal base reading.” Here are the steps:

Before use, verify the accuracy of the coating Thickness Gauge. Both Type 1 and Type 2 coating Thickness Gauges require traceable coating standards.

In random locations, prepare at least ten uncoated substrates to obtain ten readings. To avoid forgetting to take a BMR, it is better to take the measurement at the same time as the surface profile measurement is obtained.

Measure coating thickness.

Subtract the average BMR.

BMR can be deducted not only from the primer thickness but also from the cumulative layer thickness measurements obtained. As shown below:

Measured Primer Thickness: 4.9 mils

BMR: ————————————————————————————— (600,000)

Actual primer thickness from peak of surface profile: -4.3 mils

Cumulative thickness of primer and topcoat: -----9.2 mils

BMR: ————————————————————————————— (600,000)

Actual Cumulative Thickness from Peak of Surface Profile: — 8.6 mils

It is important to realize that BMR and surface profile are related, but they are not the same. Surface profile is a measure of the depth of the maximum peaks and valleys produced by blast cleaning or certain types of impact power tools. It is measured using one of the three methods described in ASTM D4417 (Standard Test Method for Field Measurement of Surface Profile of Blast Cleaned Steel) and SSPC-PA 17, which is used to determine the /Surface Roughness/Peak Count Requirements Compliance. BMR is the effect of this surface profile on the coating Thickness Gauge. A 3 mil surface profile may have an associated BMR of 0.7 million. Subtracting the surface profile from the coating thickness instead of the BMR would result in an under-reported knowledge of the actual coating thickness.