There are a variety of mixers available for laboratory use, each with its own characteristics that make them better suited for certain applications than others. Below is an overview of the types of mixers available and which ones are better suited:

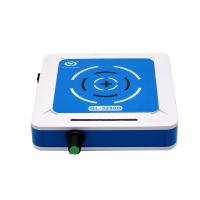

Magnetic stirrer

A magnetic stirrer uses a rotating magnetic field to rotate a (flea) stir bar immersed in a liquid and thus stir it.

Most magnetic stirrers are suitable for small quantities of low viscosity. However, some models have been developed to handle large volumes and viscosities.

The plates of a magnetic stirrer are usually made of ceramic or stainless steel.

Ceramic

Ceramic top hotplates are very chemically resistant, so they are a good choice if you are using aggressive chemicals that might splash onto the surface of the plate; the white finish also means they are great for titration or other Jobs that require clearly visible color.

Stainless steel

The stainless steel top plate does not create eddy currents (like aluminium), thus ensuring a very strong coupling and stirring action.

Stirrer electric stove

A stirrer hotplate is a stirrer combined with a hotplate. Both functions can be used independently.

The main difference between the various stirrer Heating Plates is what material the top plate is made of:

Ceramic

Ceramic top plates have good chemical resistance, so they are a good choice if you are working with aggressive chemicals that might splash onto the surface of the plate. they can provide

The maximum temperature is about 450°C, and it is easy to wipe clean.

Also, like the magnetic stirrers, the white finish means they are ideal for titrations or other jobs that require a clearly visible color.

Ceramic plates are also cold around the edges, which is great for operator safety, but may not be suitable if you need heat across the entire plate surface.

Ceramic hotplates can only be used to heat glassware, not liquids in metal containers on ceramic hotplates. They are also not suitable for sand baths and any containers that reflect heat

Returning to the surface causes cracking.

aluminum

Aluminum top plates are stronger than ceramic plates and better able to withstand accidental knocks.

They provide a consistent temperature across the entire plate and heat all the way to the edge of the plate surface.

Metal top electric stoves can also be used to heat metal containers, so this is a good choice if you are using stainless steel beakers or other metal containers.

overhead stirrer

Overhead stirrers are generally stronger than magnetic stirrers and consist of a stirrer, rod, paddle, and stand.

They are more commonly used for large volumes and viscous solutions.

Various paddle types are available for different applications as they create different stirring motions:

paddle

On low to medium speed, mix gently to better reduce turbulence. tangential flow.

Centrifugal

Medium to high speed for round containers with narrow necks. Create axial flow.

turbine

Medium to high speeds for pulling the material to be mixed from above. Minimum shear force. Reduces the risk of injury to operators when mixing elements come into contact with the vessel. Create axial flow.

dissolver

Medium to high speed. Used to paint the material to be blended from the top and bottom. High turbulence, high shear, particle reduction, radial flow.

propeller

Medium to high speed. Efficient flow design with minimal shear. Material is drawn from top to bottom with axial flow.

anchor

Drive at low speed. Excellent choice for high viscosity liquids; tangential flow.

special mixer

Submersible mixers – hermetically sealed mixers suitable for immersion in water or oil and can be used over a wide temperature range. Suitable for Water Bath, oven or Incubator.

Biomixer - Designed for stirring biological samples such as cell cultures. Provides gentle, heat-free agitation and is dust and germ resistant.