Stirring and stirring processes are common in laboratories of all shapes and sizes. Regardless of the specific application or process being performed, your lab technicians need the best equipment for the job to ensure consistent results. Unfortunately, some labs are not able to achieve the desired performance or consistency due to using the wrong mixing equipment and tools. That's why it's so important to understand your agitation options and when they are the right choice for your application.

What is a Magnetic Stirrer?

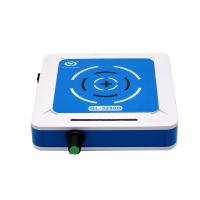

Magnetic stirrers use a rotating magnetic field to move a stir bar around in a liquid sample. The movement of the stir bar effectively mixes the sample through rapid movement and agitation. The speed of the magnetic field is user controlled, so it can be tailored to the specific sample to be stirred. These stirrers should be used with glass or other non-metallic beakers to prevent interfering magnetic fields.

Depending on the application, you can configure a magnetic stirrer with a Hot Plate to heat the sample while stirring it. By using a Hot Plate, you can mix multiple samples for different applications.

Choosing Between a Magnetic Stirrer and an Overhead Stirrer

In addition to a magnetic stirrer, you can also use an electric overhead stirrer to mix your samples. Although overhead agitators can handle larger volumes of fluid, they are not suitable for all viscosity levels. Overhead stirrers are equipped with sensors that shut off the motor if it gets too hot (especially with viscous liquids). Technicians can use overhead stirrers to control many different aspects of operation and cycle settings, but they are limited to the kinds of samples that can be effectively mixed.

If you're mixing large quantities of low-viscosity liquids, an overhead mixer may be the right choice. However, if your liquid is more viscous and you don't need the extra capacity an overhead stirrer provides, a magnetic stirrer is a better choice because you don't have to worry about overheating.