Coatings on Substrates

Coatings are usually very thin layers of material supported by a substrate. Anything placed on top of a substrate is a coating, including waxes, varnish/acrylic/enamel paints, and other types of materials that are applied to a substrate.

Coatings applied to hard substrates will naturally increase the hardness of the coating. The ceramic coating will form a layer over the car's clear coat, which helps protect the surface from harmful UV rays, pollen, bird droppings, acid rain, and other external factors that can damage the car's paint.

What is hardness?

Hardness is the ability of a solid material to resist deformation when pressure is applied. Some materials, such as metal, are harder than others, such as plastic. Macroscopic stiffness is usually characterized by strong intermolecular bonds, but the behavior of solid materials under force is much more complex. Therefore, there are different methods of hardness measurement:

Scratch hardness

Indentation hardness

Rebound hardness.

Hardness is highly dependent on ductility, elastic stiffness, plasticity, strain, strength, toughness, viscoelasticity and viscosity.

Scratch hardness scale type

In this article, we will zoom in on "Scratch Hardness". This test is used to determine the hardness of a material against scratches and abrasions.

Generally, there are 3 grades used to determine the hardness of a mineral:

Mohs Hardness Scale: It is based on relative scratch hardness with a value of 1 for talc and 10 for diamond. It's not linear, most modern abrasives are between 9 and 10.

Ridgway's Scale: An improvement on the Mohs scale, giving garnets a hardness of 10 and diamonds a hardness of 15.

Wooddell's Scale: Extending Ridgway's scale by using abrasion resistance and extrapolating the ratio from the ratio of quartz (seven) to corundum (nine) yields a value of 42.4 for the South American Brown.

How a Pencil Hardness Tester Works

Mineral flakes (Mohs, Ridgway and Wooddell) are less suitable for use with paint or film. Therefore, a standardized ASTM method for measuring thin films using a pencil hardness scale was created. Pencils are made of graphite, which has a Mohs hardness scale of only 1-2H. Think of the Pencil Hardness scale as a detailed hardness scale for graphite.

The paint industry has used pencil hardness measurements for many years to determine the hardness of clear and pigmented organic paint films. This test method has also been used to determine the cure of these coatings, especially when forced drying with heat.

This test method is especially useful in development work and production control testing in a single laboratory. It should be recognized that results obtained between laboratories may vary when different pencils and panels are used. Every effort should be made to standardize the hardness of the lead used and the technique employed.

It is also important to note that the pencil hardness test is only one of many tests used to evaluate coatings. Aside from the hardness of any coating being considered, a coating cannot be judged solely on its hardness.

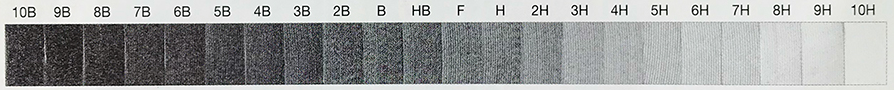

Graded pencils come in both hard and soft grades and can be found at most art or office supply stores, ranging in hardness from 10H to 9B. "H" stands for hardness, "B" stands for black, and HB stands for hard and black pencil.

The hardest is 10H, followed by 9H, 8H, 7H, 6H, 5H, 4H, 3H, 2H and H. Then there are the softest HB, B, 2B, 3B, 4B, 5B, 6B, 7B, 8B and 9B. A commonly used writing pencil is #2 (Grade HB), which is quite soft, contains more graphite, and leaves darker marks.

How the Pencil Hardness Test is Done

Typically, the coating thickness to be tested is 25.4-38.1 microns and allowed to dry for 7 days. Ambient temperature during testing may also be a factor in drying time and may affect the hardness of the coating.

Pick a pencil, and draw a line about 1/2 inch long. If the pencil scratches the surface of the coating, use softer pencils until we get the first one that doesn't scratch the coating.

Repeat the test to ensure reproducible results. There are also coatings that are so hard that a 10H pencil won't scratch them - these are rated 10H to designate their hardness.

Use this chart as a guide only. It is also important to understand that the hardness of any general purpose coating may not always be the same. In other words, if one company's polyurethane has a hardness of 3H, don't assume that all other polyurethanes have a hardness of 3H. They won't; they vary from manufacturer to manufacturer, and from product to product.

As mentioned above, the pencil hardness test is just one of many tests used to evaluate coating performance. Other tests such as Abrasion Resistance, Reverse Impact Resistance, Direct Impact Resistance, Cross Hatch Adhesion, Oxidation, Gloss Retention, UV Resistance, Yellowing, Blistering, Drying Time, Chemical/Solvent Resistance, Resistance Salt spray resistance, moisture resistance, acid and alkali resistance, VOC and HAP content are also important to the performance of coatings.