How and why should I measure the strength of my protective coating?

Modern industrial processes continue to place high demands on tools, equipment and structures. As a result, protective coatings used to shield these assets need to be able to maintain their integrity, especially in aggressive and challenging environments.

Coating strength is defined as the ability of a coating to withstand loads without coating failure (eg, peeling, loss of adhesion, cracking, wrinkling, corrosion, etc.). This property directly indicates the effectiveness of the protection provided. If the coating is not strong enough to resist the applied force, the coating can fail and put the asset at risk of severe corrosion.

Coating strength is measured by several mechanical tests. These tests involve subjecting the coating to various loading conditions while observing the coating's response. Various coating strength properties can be measured using a variety of test methods, including:

Hardness Testing

Coating hardness is a measure of a coating's ability to withstand indentation or deformation caused by external forces, such as sudden impact. This property is measured using a variety of tools including Brinell indentation, pendulum hardness and pencil hardness tests.

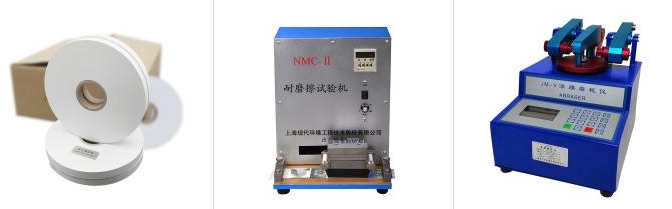

wear test

The abrasion test measures the scratch resistance of the coating. This test determines the ability of a coating to stay in place when rubbed against another surface. The Taber abrasion test and the scrub abrasion test are commonly used to measure this property.

Adhesion test

The adhesion test, as the name implies, measures the quality of the bond between the coating and the substrate. If the coating lacks sufficient adhesion to the surface, the coating may flake or flake off, leaving the substrate exposed and susceptible to corrosion. Coating adhesion testing includes peel adhesion testing, tape adhesion testing and cross-cut adhesion testing.

flexibility test

When the coating material deforms, the coating needs to be able to deform while maintaining its integrity. A common method of measuring coating flexibility is to bend a coated panel on a cylindrical or conical rod. If the coating is too brittle, bending can cause cracks.