Microindentation hardness testing (or microhardness testing) is a method used to measure the hardness of materials on a microscopic scale. Precision diamond indenters press into materials with loads ranging from a few grams to 1 kilogram. Microscopically measured indentation lengths and test loads are used to calculate hardness values. The hardness value obtained is a useful indicator of the material's performance and intended behavior in use. Conversion from microindentation hardness values to tensile strength and other hardness scales such as Rockwell hardness is available for many metals and alloys.

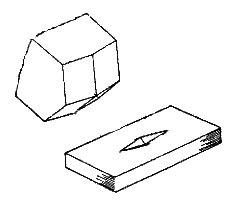

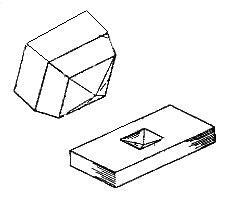

Knoop indenter Vickers indenter

Indentations are usually made using square-based pyramidal indenters (Vickers hardness scale) or elongated diamond-shaped indenters (Knoop hardness scale). The Tester applies the selected test load using its own weight. The length of the hardness imprint is accurately measured by an optical microscope using a wire eyepiece or a video image and computer software. The hardness value is then calculated using the test load, indentation length, and shape factor of the type of indenter used for testing.