NDJ-4 rotary viscometer can measure the viscous resistance and dynamic viscosity of liquid in a large range. It can be widely used in the viscosity determination of various fluids such as oil, paint, plastic, food, medicine, and viscometer.

Install

1. Take out the storage box, fixing bracket and lifting column from the packing box.

2. Screw the lifting column into the screw hole at the rear of the fixed bracket, and face the toothed surface on the column to the rear of the bracket, and tighten the hex nut with a wrench to prevent the column from rotating.

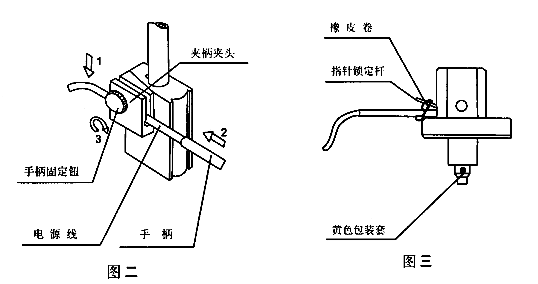

3. Turn the knob of the lifting chuck to check the flexibility and self-locking property of the lifting chuck. If it is found to be too loose or too tight, use a Phillips or flathead screwdriver to adjust the tightening screw of the chuck at the rear of the lifting chuck to make it work.

4. It is better to lift up and down tightly to prevent automatic fall after installing the viscometer.

5. Open the storage box, take out the viscometer, install the viscometer on the lifting chuck, tighten the handle fixing screw, take off the rubber band on the pointer control rod, unscrew the screw at the lower end of the instrument, and take off the yellow packaging ferrule.

6. Adjust the level adjustment screw to keep the instrument level.

7. After the above preparations are completed, connect the power supply.

Operation

1. Prepare the liquid to be tested, put it in a beaker or a straight container with a diameter of not less than 70mm, and accurately control the temperature of the liquid to be tested.

2. Install the protective frame on the instrument (screw right to install it, turn left to remove it).

3. Screw the selected rotor into the connecting screw (rotate to the left to install, and rotate to the right to remove). Rotate the lifting knob to lower the instrument slowly, and gradually immerse the rotor into the measured liquid until the rotor liquid level mark is parallel to the liquid surface. Adjust the level of the instrument, turn on the motor switch, turn the variable speed knob to make the required speed number upward, align with the speed indicator point, and the rotor rotates in the liquid. After several rotations, generally (20-30) s, or according to the specified time, the pointer can be read when it becomes stable. Press the pointer control lever to fix the reading, and turn off the motor when the pointer turns to the reading window

(Note: 1. Do not use too much force. 2. When the speed is slow, you can read directly without using the control lever). At this time, the pointer stops in the reading window, and the measurement data can be obtained. If the pointer is not in the reading window after the motor is turned off, you can continue to press the pointer control lever to turn on and off the motor repeatedly. After several exercises, you can master it proficiently, make the pointer stop in the reading window, and read the data.

4. When the value pointed by the pointer is too high or too low, the rotor and the rotating speed can be changed, and the reading must be between 30-90 on the scale.

5. Selection of range, coefficient, rotor and speed:

a.先大约估计被测液体的粘度范围,然后According to量程表选择适当的转子和转速。

如测定约3000mPa.s左右的液体时可选用下列配合:2号转子、6转/分 或 3号转子、30转/分

b.当估计不出被测液体的大致粘度时,应先设定为较高的粘度,试用从小体积到大体积的转子和由慢到快的转速。原则是高粘度的液体选用小体积的转子和慢的转速,低粘度的液体选用大体积的转子和快的转速。

c.系数:测定时指针在刻度盘上指示的读数需要乘上系数表上的特定系数才为测得的动力粘度(mPa.s)。

即η=k×α

式中 η——动力粘度

K——系数

α——指针所指粘度(偏转角度)

d.频率误差的修正:当使用电源频率不准时,可按下列公式修正。

实际粘度=指示粘度×(名义频率/实际频率)

e.常用粘度单位换算:

《常用动力粘度单位换算》:

1厘泊(1cP)=1毫帕斯卡·秒(1mPa.s)

100厘泊(100cP)=1泊(1P)

1000毫帕斯卡·秒(1mPa.s)=1帕斯卡·秒(1Pa.s)

《动力粘度与运动粘度的换算》:

η=ν×ρ 式中 η——试样动力粘度(mPa.s);ν——试样运动粘度(mm2/s)

ρ——与测量运动粘度相同温度下试样的密度(g/cm3)

注意事项

1.本仪器适用于常温环境下使用。

2.仪器需要在指定频率和电压允差范围内测定,否则会影响测量精度。

3.尽量利用支架固定仪器使用,如手持操作应保持仪器稳定和水平。

4.装卸转子时应小心操作,装拆时应将连接螺杆微微抬起进行操作,不要用力过大,不要使转子横向受力,以免转子弯曲。

5.装上转子后不得将仪器侧放或倒放。

6.一定要在电机运转时变换转速。

7.连接螺杆和转子连接端面及螺纹处应保持清洁,否则将影响转子的正确连接及转动时的稳定性。

8.仪器升降时应用手托住仪器,防止仪器自动坠落。

9.每次使用完毕应及时清洗转子(不得在仪器上进行转子清洗),清洁后要妥善安放。

10.不得随意拆动调整仪器零件,不要自行加注润滑油。

11. When the instrument is moved and transported, the pointer control rod should be surrounded by a rubber band, and put into the yellow packaging ferrule to support the connecting screw rod, and then tightened with the screw.

12. Many suspensions, emulsions, polymers and other high-viscosity liquids are "non-Newtonian liquids". Its surface viscosity changes with the change of shear speed and time, so it is normal for the results to be inconsistent when measured under different rotors, speeds and times, so the viscosity value measured by this instrument for non-Newtonian liquids can only be used as a reference value (Generally, the measurement of non-Newtonian liquids should be carried out according to the rotor, rotational speed and duration specified in the measurement requirements: or the conditions and environment of fixed measurement, and comparative measurement to verify whether the viscosity is qualified).

13. Accurate values can be measured by doing the following points:

a ) Accurately control the temperature of the measured liquid.

b ) Immerse the rotor in the liquid to be measured for a long enough time and keep the temperature constant so that it can be consistent with the temperature of the liquid to be measured.

c ) Ensure the uniformity of the liquid.

d ) Place the rotor in the center of the container as much as possible during the measurement.

e ) Prevent air bubbles from adhering to the bottom of the rotor when the rotor is immersed in the liquid.

f ) Change the rotor or speed to make the reading on the dial higher.

g ) Assay using a protected frame.

h ) Ensure the cleanliness of the rotor.

i ) When the power frequency is not accurate, it should be corrected according to the correction formula.

j) Operate strictly in accordance with the operating rules.