Solvent resistance is evaluated by solvent wipe test – ASTM D4752 and NCCA 11-18.

This test method is used to determine the degree of cure of a baked film by its resistance to specific solvents.

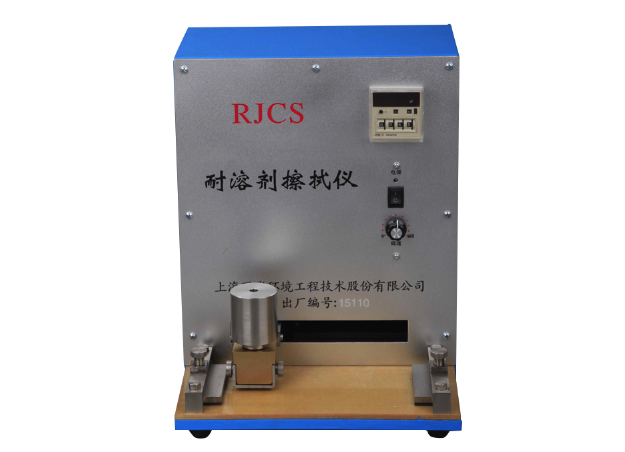

Solvent wipe tests are usually performed using methyl ethyl ketone (MEK) as the solvent. MEK resistance or degree of cure is suitable for topcoats and primers. (Testing instrument: solvent-resistant wiper)

ASTM D4752 involves rubbing the surface of the baked film with a cheesecloth soaked in MEK until the film cracks or cracks. The type of cheesecloth, stroke distance, stroke rate and approximate applied pressure are specified. The rub is counted as two rubs (one forward rub and one backward rub constitutes two rubs).

This test is widely used in the coatings industry because it allows a quick estimate of the degree of cure without waiting for long-term exposure results. Tests with bi-reflective zinc-rich primers have been reported to have a good correlation with the cure of the primer as determined by diffuse reflectance infrared spectroscopy.

Reference: ASTM D4752 Standard Test Method, MEK Resistance of Ethyl Silicate (Inorganic) Zinc-Rich Primers by Solvent Mill.