The evaluation of powder coating surface properties is very important. In the evaluation of the mechanical properties of powder coatings, the most basic thing is to first determine the adhesion.

If the coating does not adhere to the substrate, all bets are off. Impact resistance is poorer, hardness measurements may be inaccurate, and even wear resistance may be adversely affected. ASTM D3359 - Measuring Adhesion by Tape Test describes several techniques. ASTM D3359A requires a sharp blade to make a simple "X" cut in the coating. It is very important to use a clean, fresh blade to ensure an accurate cut. Then apply the designated tape to the "X" cut and quickly pull from the surface.

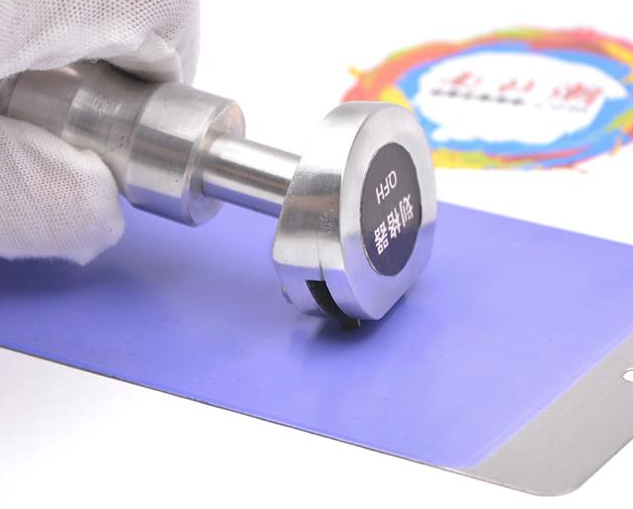

A more complex adhesion test is described in ASTM D3359B. This method guides you through the cross-hatch pattern of your cuts (6 x 6 or 11 x 11 cuts). Cutting can be done with a sharp blade or a specially designed device with multiple cutting edges. The same number of cuts are made in parallel and another set of cuts at 90° to the first set forms a lattice pattern. Clean the cut area with a brush and apply tape over the cross-hatch pattern. Quickly remove the tape and check the test area for adhesion. The ASTM method provides a scoring system, with accompanying images, describing the scoring range from 5B (100% adhesion) to 0B (0 to 35% adhesion).

ISO 2409 covers similar test methods as ASTM D3359B. Interestingly, the grading system used in this international standard uses the opposite value from the ASTM standard. A "0" rating indicates 100% adhesion, progressively worse adhesion is indicated by a numerical rating from "1" (loss of 5%) to "5" (loss of 100%). This highlights the need to be very careful when citing test methods when reporting results.

Wet adhesion is another, more aggressive technique, and the methods and testing methods considered depend on the application and service expectations of the coating. Pipe coatings use the tests described in Canadian Specification CSA Z245.20. The test involves immersing a coated sample in tap water at 73°C for 24 hours, after which the test panel is removed and a 30 mm x 15 mm rectangle is cut out of the coating. Adhesion is measured by attempting to pry the coating away from the substrate with a knife. Another method is to test wet adhesion by first making an "X" shaped cut in the coating and then immersing the sample in water at 90°C for 2 hours. If the paint peels off from this exposure, it indicates poor adhesion. I like to use this material on particularly difficult substrates, such as stainless steel or polished aluminum.