Characterizing the deformation resistance of coatings is an interesting proposition. Some refer to impact resistance (ASTM D2794) as the gold standard for measuring flexibility. In reality, one size does not always fit all. First, let's discuss the factors that affect flexibility. The thickness and ductility of the substrate have a major impact on the flexibility of the coating. For example, thicker gauge steel deforms less than thinner steel, so the coating experiences less stress under the same conditions. Additionally, the thickness of the film affects flexibility. Thinner films are almost always more flexible than thicker films, so it is important to keep coating thickness within specification. Another factor is temperature. Warm coatings are generally more flexible, while cold coatings are more likely to break under stress. Certain coating specifications require sub-zero temperatures to test deformation properties. It is important to test flexibility at the specified temperature. Another problem - different metals (alloys actually) have different ductility. Therefore, 20 gauge 3003 grade aluminum deforms much more than 20 gauge 1008 grade mild steel. So 100 inch pounds. The degree of deformation of 3003 aluminum by impact is significantly greater than that of 1008 steel of the same thickness.

rapid deformation

A common test for coating flexibility is rapid deformation induced by an impact Tester (ASTM D2794 Standard Test Method for Resistance of Organic Coatings to Rapid Deformation (Impact)). In North America, a 4.0-pound weight is lifted at the calibration point with a contact point radius of 0.625 inches and dropped onto the coated surface. The distance (height) times the weight determines the force in inch-pounds. This impact creates a dent in the substrate/coating. Failure is determined by the maximum force that will not cause the coating to crack. Impact resistance can be measured by dropping a heavy object on the surface of the coating (forward impact) or from behind the coating (reverse impact). The ISO standard for impact resistance (ISO 6272) uses a 20 mm diameter ball at the point of impact and 1.0 kg at the point of impact. weight. Shock is well quoted in Nm (Newton Meters).

Impact resistance testing (Method 6226 – Federal Test Standard 141B) is more common in the aerospace industry. This test also employs a drop weight similar to ASTM D2794; however, the impact head has two sides, each with four impactors of different radii. Using grade 2024 aluminum substrate on both sides, elongation from 0.5% to 60% can be determined.

Impact resistance testing is useful for determining the inherent resistance to sudden mechanical shock to a coated surface. Although it is imprecise, it is also a decent factor in determining treatment. Most powder coatings do not achieve final impact resistance until they are fully crosslinked.

Impact Test

A common test for coating flexibility is rapid deformation induced by an impact Tester (ASTM D2794 Standard Test Method for Resistance of Organic Coatings to Rapid Deformation (Impact)). In North America, a 4.0-pound weight is lifted at the calibration point with a contact point radius of 0.625 inches and dropped onto the coated surface. The distance (height) times the weight determines the force in inch-pounds. This impact creates a dent in the substrate/coating. Failure is determined by the maximum force that will not cause the coating to crack. Impact resistance can be measured by dropping a heavy object on the surface of the coating (forward impact) or from behind the coating (reverse impact). The ISO standard for impact resistance (ISO 6272) uses a 20 mm diameter ball at the point of impact and 1.0 kg at the point of impact. weight. Shock is well quoted in Nm (Newton Meters).

GE Shock Test (Method 6226 – Federal Test Standard 141B) is more common in the aerospace industry. This test also employs a drop weight similar to ASTM D2794; however, the impact head has two sides, each with four impactors of different radii. Using grade 2024 aluminum substrate on both sides, elongation from 0.5% to 60% can be determined.

Impact resistance testing is useful for determining the inherent resistance to sudden mechanical shock to a coated surface. Although it is imprecise, it is also a decent factor in determining treatment. Most powder coatings do not achieve final impact resistance until they are fully crosslinked.

Bending test

Measuring the elongation properties of coatings requires a slow deformation test method. These tests are usually specified if the coating will undergo some type of post-forming after curing. Coated sheet stock is sometimes used in a fastening or compression process to abut the sheet during assembly. Performing a slow deformation test ensures that the coating can withstand this type of stress. In other cases, slow deformation is just another feature of the toughness of the coating.

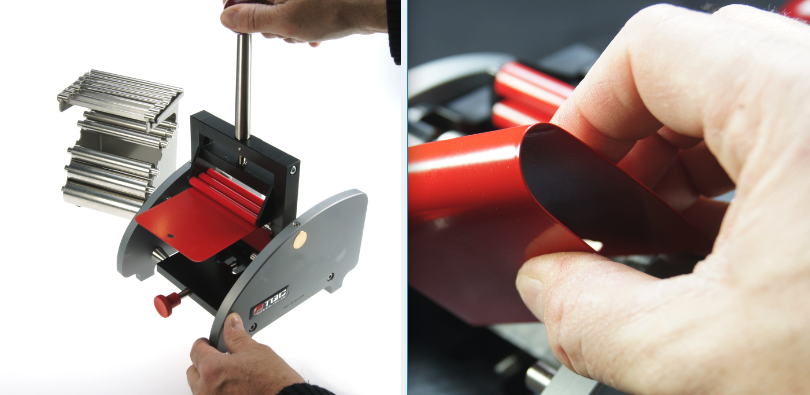

The "T-bend" test (testing instrument: bend Tester) is commonly specified by the precoat-postform coating community. ASTM D4145 (ISO 17132) describes how to perform this test. Basically, the coated test panel is bent or folded 180°. The first bend is "0-T", meaning there is no panel thickness between the two outer surfaces of the coated panel. Check the curved edges of the coating for cracks. If no cracks appear, the coating is rated "0-T". If cracked, the test panel is bent an additional 180°, which will result in doubling the thickness of the panel between the outer surfaces of the test panel. This condition means "1-T". Check the edges of the coating. The test panel was repeatedly folded 180° until there were no visible cracks at the edges of the coating. Acceptance is expressed as the amount of "thickness" that exists between the outer surfaces of the panel without cracking of the coating.

Another slow deformation technique is described in ISO 1520 Paints and varnishes – Cupping test. The test method, most common in Europe, involves slow pressing into a hemispherical fixed-coated test panel with a diameter of 20 mm. Identify the point of failure when the coating develops cracks in the finish. The above issues of metal type, gauge and temperature all apply here. Test equipment for this method comes in the form of manual or automatic instruments. It is recommended to use a magnifying glass to determine the initiation point of the crack.

The pipe coating industry uses the slow deformation test described in CSA Z245.20. This test requires that a 25 mm x 200 mm x 6.4 mm steel coupon be coated with not less than 300 microns (12 mils) of epoxy powder coating. The coated test bars were cooled to -30°C for at least one hour before being deformed through a mandrel in a hydraulic press. This bending process needs to be performed within 10 seconds after taking out the cooled sample.