What is the Taber Abrasion Test?

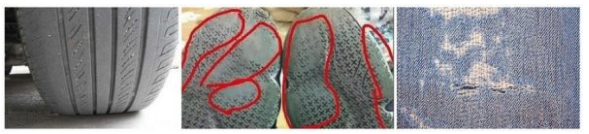

Wear: In the relative motion of objects in contact with each other, the phenomenon of continuous loss, transfer or residual deformation of surface materials is called wear, which is the inevitable result of friction. Most wear and tear not only consume materials and resources, but also directly affect the life and reliability of objects.

The wear process is very complex, and there are many factors that affect the wear rate: different materials, different wear methods and test environments. The Taber abrasion test is a method of simulating wear and tear of materials in the laboratory and is used on a wide variety of materials including plastics, coatings, laminates, leather, paper, textiles, flooring, and more.

In this article, the ASTM D4060 test method is used to explain how to perform the Taber abrasion test in four ways.

1 test range

The ASTM D4060 test method covers the determination of the abrasion resistance of organic coatings produced by Taber Abraser on coatings applied to flat rigid surfaces such as metal panels.

2 Sample pretreatment

Sampling is based on the specification of available material or agreement between buyer and seller. If there is no relevant description, take the width of the whole piece of fabric and the length of at least 50cm, and should be sampled at 1m from the end of each piece of fabric.

The sample is a disc or a square with a ø6.5mm diameter hole in the center of the sample. The test sample is a circle with a diameter of 100mm or a square with a diameter of 100mm*100mm. The thickness of the sample should not exceed 6.3mm, and the test thickness of the sample can be adjusted.

Unless otherwise agreed between the buyer and the seller, place the coated panels at 23±2°C and 50±5% relative humidity for at least 24h. Test in the same environment or immediately after removal from it.

3 test procedures

3.1 If wear index or weight loss is to be reported, weigh the test sample to the nearest 0.1 mg and record the weight.

3.2 When it is desired to calculate the wear coefficient in mils, the coating thickness of the specimen shall be measured at several locations along the path to be worn and then averaged.

3.3 Install the sample on the turntable platform of the Taber abrasion Tester (abrasion testing machine), with the surface to be ground facing up, and fix it with splints and nuts. Lower both grinding wheels with a certain load so that they just touch the sample surface. Set the number of revolutions, turn on the vacuum, and start the test.

3.4 Subject the specimen to the specified number of abrasions, or until coating abrasion is observed. When determining wear points, stop the instrument at intervals to examine the specimen.

3.5 Remove any excess wear remaining on the specimen with a light brush, then reweigh the specimen.

4 calculations

4.1 Wear index: 1000 times the loss of milligrams per cycle, the unit is mg.

I = 1000(A - B) / C

in:

A = weight of sample before abrasion, mg

B = weight of sample after abrasion, mg

C = number of abrasions recorded

4.2 Weight loss: Weight loss (in milligrams) determined at the specified number of cycles.

L = A - B

in:

A = weight of sample before abrasion, mg

B = weight of sample after abrasion, mg

4.3 Abrasion Cycles per Mil: The number of abrasion cycles required to penetrate the film into the substrate per mil of film thickness.

W = D / T

in:

D = number of abrasions required to wear the coating down to the substrate

T = coating thickness, mil (0.001 inch) (to one decimal place).

NOTE: When calculating wear cycles, it is recommended to discard the first and last readings as the first and last readings may be affected by uneven surfaces and the last may be affected by wear of the substrate part.

The Taber abrasion test is very effective and is a commonly used test method when evaluating the abrasion resistance of coatings on substrates. It can not only comply with ASTM D4060 standard, but also ASTM D3884, ASTM D3389 and ISO 5470 etc.