Contrast ratio is mainly used to test the hiding power of products in national standards. To evaluate the hiding power of paint, it is not only the wet hiding power of construction, but also the hiding power of the paint film after drying. Contrast ratios reflect the hiding power of the wet product and can reveal the final application of the paint. This article is about the uncertainty assessment of the measurement results of the surface contrast ratio of the paint film, where the contrast ratio mainly refers to the ratio of the reflectance of the same paint film applied to the black and white substrates with specified reflectance. The contrast ratio shows the ability of white and light-colored paints to eliminate the color of the substrate. The lower the contrast ratio of the paint, the worse the hiding performance of the product, and it cannot eliminate the color of the substrate. In the actual use of daily construction, the reflectance on the black background and the reflectance on the white background are measured with a reflectance meter, and the contrast ratio is obtained by dividing the reflectance on the black background by the reflectance on the white background. The article mainly introduces the detection of the contrast ratio of the paint film by using the reflectance measuring instrument, and evaluates the uncertainty of the detection results.

1 Introduction

Contrast ratio refers to the ratio of reflectance of the same paint film applied to black and white substrates of specified reflectance. The contrast ratio reflects the ability of white and light-colored paints to eliminate the color of the substrate. The lower the contrast ratio of the paint, the worse the hiding performance of the product, and it cannot eliminate the color of the substrate.

The reflectance meter is an instrument used to measure the reflectance of the surface of paint, coating, ceramics, etc., and to measure the surface contrast ratio of the paint film by calculation. The measurement principle is to define a satisfactory surface with a spectral diffuse reflectance of 100% as a reflectance of 100, and an absolutely black surface with a spectral reflectance of zero as a reflectance of 0. Reflectivity is a dimensionless quantity. In practical applications, the reflectance on the black background and the reflectance on the white background are measured with a reflectance meter, and the contrast ratio is obtained by dividing the reflectance on the black background by the reflectance on the white background.

The reflectance measuring instrument is composed of lighting system, detection system, data processing and display system, etc. The working principle of the reflectance measuring instrument is to use the photoelectric integration method to compare the radiance reflected by the surface of the measured sample with the radiance of a complete diffuser under the same irradiation conditions. The signal is amplified, A/D converted, and processed by a computer. , and finally the reflectance value (reflection factor Y ) is displayed.

The light source, illumination and detection conditions of the reflectance measuring instrument shall comply with one of several conditions stipulated in GB/T 3978 -1994 "Standard Illumination Objects and Illumination Observation Conditions", namely (1) Diffuse illumination vertical detection (d /0); (2) Diffuse detection with vertical illumination (0/d); (3) Vertical detection with 45° illumination (45/0); (4) 45° detection with vertical illumination (0/45).

The reflectance meter usually adopts the relative comparison method, which needs to be compared with the measurement standard. Therefore, the reflectance meter must be equipped with at least one effective traceable standard reflector to calibrate the instrument. Measurement methods usually include single-beam measurement and double-beam measurement.

Measurements of single-beam reflections are usually performed by substituting measurements with a standard reflector. Place a standard reflector with a known reflectance value R 0 in the sample window, and measure its reflected flux signal as I 0 , then replace the standard reflector with the sample to be tested, and measure its reflected flux signal as I , Then the reflectance of the sample to be tested can  be obtained by the formula.

be obtained by the formula.

When measuring with a double-beam optical path, use a reference reflector similar to the standard reflector in the reference window, place the standard reflector in the sample window, perform 100% baseline correction, then replace the standard reflector with the sample to be tested, and measure the sample Relative to the reading R 1 of the reference reflector, the concentration of the sample to be tested can be obtained by the formula.

The above-mentioned diffuse reflectance measurement method is widely used because of its simple instrument and convenient operation. However, this method is a comparative measurement method and requires a standard reflector as a transfer standard. The measurement uncertainty is also related to the uncertainty of the transfer standard. Especially when the measurement conditions of the sample to be tested are different from the measurement conditions of the transfer standard, a large uncertainty will be introduced. 2 Measurement method

On the colorless transparent polyester film (thickness 30μm ~ 50μm), or on the cardboard with half and half black and white background colors, evenly coat according to 5.2.2 of "GBT 9756-2001 Synthetic Resin Emulsion Interior Wall Coatings" The paint to be tested shall be placed for at least 24 hours under the conditions specified in 5.2.1.

Use a reflectance meter to measure the reflectance of the coating film on the black and white bottom surface. The reflectance of the black and white work board or cardboard is: black: not more than 1%; white: (80 ± 2)%. If the polyester film is used as the substrate to prepare the coating film (it is recommended that you use a Film Thickness Gauge), the painted polyester film is attached to the instrument with a few drops of No. 200 mineral spirits (or other suitable solvents). Black and white work board, so that there is no air gap, then measure the reflectance of each painted polyester film at least four positions, and calculate the average reflectance RB (black board) and RW (white board). If the coating film is prepared with a cardboard with black and white base colors, measure the reflectance directly on at least four positions on the black and white base color coating film, and calculate the average reflectance RB (on black paper) and RW (on white paper) respectively. superior).

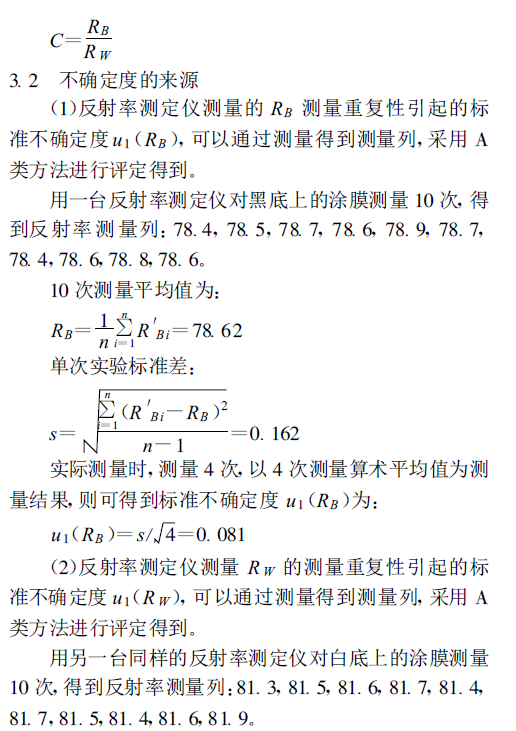

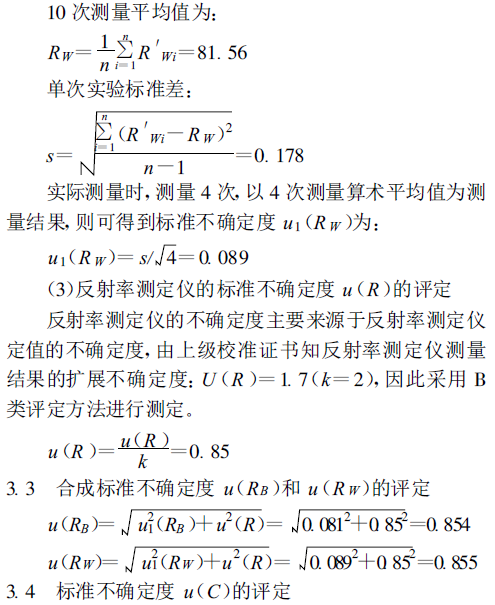

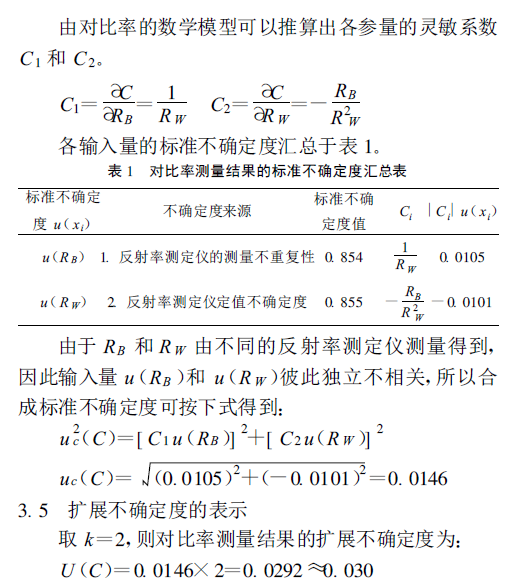

3 Uncertainty assessment of measurement results

3.1 Mathematical model

4 Conclusion

The above are some discussion and analysis of the author on the uncertainty evaluation of the measurement results of the surface contrast ratio of the paint film. During the detection process of the surface contrast ratio of the paint film, two identical reflectance measuring instruments were used to measure RB and RW respectively. In this way, the correlation caused by using the same reflectance measuring instrument to detect RB and RW can be avoided, and the evaluation of uncertainty is optimized. The final contrast ratio measurement result is C =0.964, and the uncertainty is u(C)=0.030(k=2).

Zhang Hongjun's "Uncertainty Evaluation of Paint Film Surface Contrast Ratio Measurement Results"