1. Fineness

The fineness is to express the degree of dispersion of the pigment in the paint. Its detection is to spread the paint into films with different thicknesses, and observe at what thickness the particles appear. At this time, the thickness is the fineness of the paint, and the unit is microns. There are several different measurement and expression methods for fineness. When using the fineness method, the reading time should not be too long, otherwise it is not suitable for reading. In the process inspection and final inspection, it should be inspected at least three times. When the fineness of the coating is not up to standard, it is better to inspect it several times to see what the average effect is. When encountering epoxy series coating products, you can add a little more thinner and then reapply. test.

Scraper Gauge

2. Viscosity

Viscosity is an item that expresses the rheological properties of a fluid, and it is the degree of internal resistance to the fluid that resists flow, also known as the coefficient of friction. The Stormer viscosity is obtained by converting the weight of Zhu code, expressed in KU. This viscometer is more suitable for laboratories with frequent use and is easy to clean. Other

A large category is counted in seconds, starting when the paint in the cup flows out from the lower port, and counting the end time when the linear flow of paint in the cup is broken. Measuring instruments mainly include Tu-4 cups, Ford cups, ISO cups, etc. The difference between them is the capacity of the cup and the hole diameter of the cup. It is important to note that temperature has a greater effect on viscosity,

The general rule is to measure the viscosity at 23.0°C±0.2°C. When measuring the viscosity with Tu-4 cup, etc., if you strive for accuracy, the cup must be soaked in constant temperature water at 23°C for more than 15 minutes before use .

Viscosity Cup

3. Solid content

The solid content refers to the part of the paint component that remains to become the coating film after construction, and it is also a test of whether the raw material or finished product is within the specified range. The method is to place a certain amount of sample in an open container, put it in a 1os-11o·c oven and bake it for 3h, then take it out, and calculate the remaining nitrogen. In addition, the determination of solid content in the process inspection is generally 1so·c, lh. In actual production, the solid content of epoxy coatings 1so·c and lh is about 0.4% lower than that of 1os·c and 3h, especially for curing agents. According to experience, every time the temperature is increased or decreased by 14 degrees Celsius, the baking time will be shortened or extended by half an hour.

GB/T 1725 2007 "Determination of non-volatile content of paints, varnishes and plastics" stipulates the determination of paints, varnishes, binders for paints and varnishes, polymer dispersion and polycondensation resins such as phenolic resins (resol , novolac resins, etc.) are also applicable to dispersions containing pigments, fillers and other additives such as thickening aids and coalescents.

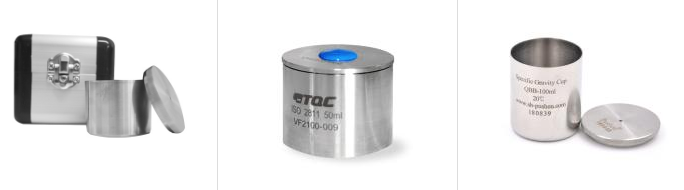

4. Density

The purpose of measuring the density of paint is mainly to control the quality of the solid volume in the product packaging container. This test item can reflect the implementation of the production process to a certain extent, especially in zinc powder coatings. If a certain amount of zinc powder is missing in the feed, the density will be much smaller.

Density specific gravity cup

5. Dryness, sagging, state in container and storage stability

The process of physical or chemical change from a fluid layer to a solid coating film when the coating is applied to the surface of the object is called the drying of the coating film. It is customary to divide the drying of the coating film into three stages: touch dry, semi-hard dry and hardened dry.

Dry-to-touch means that the film is tacky when lightly touched with a finger, but there is no paint staining. Semi-hard dry means that the film is lightly rubbed with fingers without leaving scratches. Hardened and dry means that the surface of the coating film is pressed firmly with the thumb, and the coating film does not leave fingerprints and is not loose, and after rapid rubbing with fingers, there is no scratch on the surface of the coating film.

When doing the sag test, put the sag meter flat on the tin plate, pour a certain amount of sample and drag the sag meter horizontally at a uniform and slightly slow speed, so that more accurate results can be obtained.

The shelf life of various paint products is generally one year, and that of epoxy zinc-rich paint is half a year. Alkyd paint and chlorinated rubber paint are prone to skinning when the shelf life exceeds the alkyd resin. Some colors are especially composed of two or two colors. The re-color paint made by blending more than one kind of pigments is prone to pigment floating phenomenon during long-term storage, which is caused by different pigment densities. Just stir well in use.

Flow meter

6. Coating color, gloss, coating appearance and sandability test

The above three inspection items all need to be inspected after spraying the board. Generally, it is sprayed to the film thickness specified in the standard, and the inspection is carried out after the board surface is dried. The judgment of color is based on visual test and color difference meter, and the final judgment depends on visual test. To check whether the color is qualified or not, the standard Color Chart is generally used as the benchmark, and the appearance of the previous batch is an important reference. The color of the latter batch only needs to be between the standard Color Chart and the color of the previous batch of samples. It can slowly approach the color of the standard Color Chart. In some relatively beautiful and bright colors, different diluting amounts and different film thicknesses will cause color differences. Therefore, it is necessary to operate and implement according to the standard regulations as much as possible to minimize errors.

After the coating film is dry, it is also necessary to check whether there are any abnormalities such as impurities and particles on the surface of the board to determine whether the appearance of the coating film is qualified, and use a gloss meter to test its gloss. The gloss meter consists of a light source part and a receiving part. The light emitted by the light source is parallel or slightly converging to the surface of the paint film after passing through the lens. The reflected light is received and converged by the lens, and is received by the photocell. The photocell generates current, and the gloss reading is obtained by means of a galvanometer.

GB/T 1770 — 2008 "Determination of Grindability of Coating Film and Putty Film" standard stipulates that after the coating film and putty film are polished for a specified number of times under a specified load, the changes in the surface of the coating film and the difficulty of grinding It is an empirical test method to evaluate its grinding resistance. This standard applies to the determination of the sandability of paint films and putty films, to liquid or powder paints and varnishes, and to wet or dry films and their raw materials.

Colorimeter