Shear viscosity is defined as the ratio of shear to shear strain rate at the strain rate of interest.

Although viscosity is often quoted as a number without reference to strain rate, it is actually a function of strain rate. The strain rate dependence and, in some cases, time dependence need to be determined if meaningful correlations with coating phenomena are to be made. In the case of paints, the shear strain rates of interest range from about a few thousand reciprocal seconds (such as during spraying) down to reciprocal hundredths of a second (subsequent application).

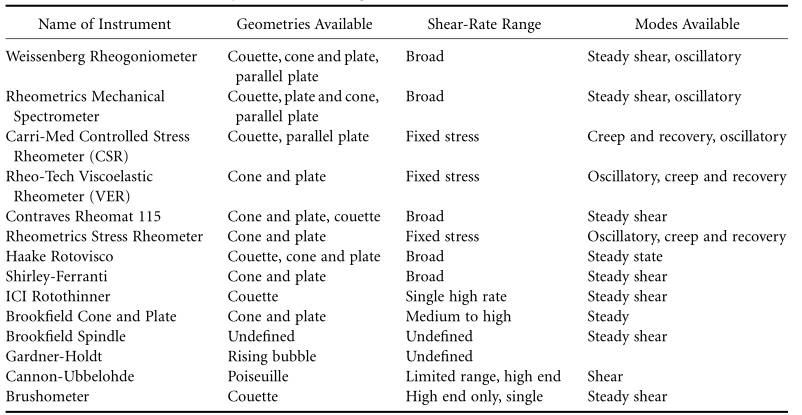

There are a variety of techniques that can be used to measure the viscosity of paint formulations. Table 2.2 lists some of the instruments with single or indeterminate strain rates that should be avoided in research.

Table 2.2 Some commercially available rheological viscosity instruments

Coating Rheology. Viscosity needs to be measured over a wide range of strain rates if it is to be meaningfully correlated with coating phenomena.

The most accepted technique to determine the strain rate dependence of viscosity is to use constant strain rate experiments in torsion. This can be done in cone-plate (low speed) or concentric cylinder geometry (high speed). However, oscillatory or dynamic measurements are also often used for the same purpose. Assuming that the shear strain rate and frequency are equal, the complex viscosity is equal to the steady state constant rate

Viscosity (i.e. the Cox–Merz rule applies). However, the applicability of the Cox-Merz rule is by no means universal and needs to be demonstrated before a dynamic measurement can be substituted for a steady-state measurement. In general, the capillary technique used in several commercial instruments is not suitable for coating studies because it is better suited for measuring viscosity at higher strain rates.