Materials

Generally meet ASTM D-3359 standard crosshatch. In the kit you'll find a blade, a blade holder/handle, a hex wrench for changing the blade, an extra set screw, a small stripping and cleaning brush, a lighted magnifying glass, and a roll of test tape.

You'll also need an eraser on the end of the pencil.

test specimen

In the field, you will test the actual coated structure or item to be evaluated. In the lab, you apply the material to be tested to panels with the proper composition and surface conditions. Either way, the test surface needs to be flat. You can check for evenness with a straight edge like a steel ruler.

program

1. Make sure your specimen is at room temperature (or other mutually agreed temperature) and on a firm base.

2. Select an area free of spots and minor surface defects. Under magnifying glass illumination, use the crosscut tool to make parallel cuts as follows:

3. For dry film coatings less than or equal to 2.0 mil (50 µm) thick, use a fine spatula (1.0 mm spacing). For coatings between 2.0 mils (50 µm) dry film thickness

4. Make the first cut about 3/4" (20mm) long. Just apply enough pressure to steadily cut the film into the substrate.

5. After cutting, gently remove any dislodged flakes or ribbons from the film with the tool kit's brush.

6. Next, make a second cut at 90 0 and center the original cut to create a grid pattern in the film.

7. Brush the area again and check the cut to make sure you have reached the substrate. If not, create another mesh elsewhere.

8. Peel off two full turns of kit test tape and discard. Remove another length at a steady pace (don't pull), and cut into pieces about 3 inches (75 mm) long.

9. Place the center of the tape over the grid and smooth it into place. To maintain good contact with the film, use a pencil eraser to rub the tape firmly. The color underneath the tape helps you determine when a good contact has been made.

10. Wait about 90 seconds, then remove the tape. Grab the free end and quickly (without shaking) pull it back as far as it will go back 180 degrees. 11. Use the kit's illuminated magnifying glass to inspect the mesh area for coating removal. Adhesion of the coating was scored according to the classification criteria below; see the "Results Classification" table that follows.

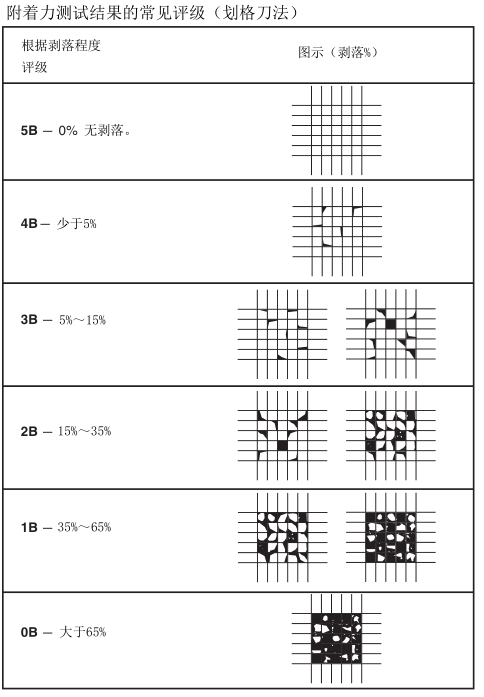

The edges of the 5B cutouts were completely smooth; none of the coating on the mesh squares had come off.

4B Small flakes were detached at the point of intersection, affecting no more than about 5% of the area.

3B Small flakes fall off along the edges and intersections of the incisions.

About 5% to 15% of the mesh is affected.

2B Coating peeled off along the edges and sections of the square. About 15% to 35% of the mesh is affected.

The 1B coating peeled off in long strips along the cut edges, and the entire square fell off.

Between 35% and 65% of the grid was affected.

0B peeling is worse than 1B grade.

Report

Report the number of tests, their average and range, and where the failure occurred (e.g., between first coat and substrate, between first coat and second coat, etc.). Note the substrate used, the type of coating and the curing method.

If the adhesive strength of the tape has been determined in accordance with Test Methods D 1000 1 or D 3330 2, please report the results with the adhesion rating. Otherwise, the specific tape used is reported.

Precision and Bias

Use the following criteria to judge the acceptability of the results.

Repeatability—If the adhesion is uniform on the surface being tested, two measurements by the same operator should not differ by more than one grade.

Reproducibility—Test results (average of two measurements) obtained by different operators should not differ by more than two grades.

Bias cannot be established for these test methods.

1 D 1000 Test Methods for Pressure-Sensitive Adhesive Tapes for Electrical and Electronic Applications; Annual Book of ASTM Standards, Volume 1. 10.01.

2D 3330 Test Method for Pressure-Sensitive Tape at a Peel Angle of 180°; Annual Book of ASTM Standards, Volume 1. 15.09.