C.1 Alkali resistance test

C.1.1 The following preparations should be made for the test

(1) Trial mold, the size is 100mmx10ommx100mm;

(2) Coating wet Film Thickness Gauge, the measuring range is 0~500m;

(3) Microscope Thickness Gauge

C.1.2 The test should be carried out according to the following steps

C.1.2.1 Concrete blocks for the test shall be concrete of not less than C25, and the cement shall be 32.5 grade ordinary Portland cement . Six concrete blocks shall be molded with a 100mmx100mmx100m trial mold and shall be cured for 28 days.

C.1.2.2 Fabrication of coated specimens, wash any non-formed surface of each concrete block with drinking water and a steel wire brush. If there are pores, fill them with ordinary Portland cement mortar.

After the treatment, put it indoors, cover it with paper, dry it naturally for 7 days, and then paint it; according to the requirements of the instruction manual, paint the supporting paint for the test in the order of bottom layer, middle layer and surface layer respectively, and control the coating at the same time. The total dry film thickness of each layer is 250~300m. During the coating process, use a wet Film Thickness Gauge to detect the wet film thickness of each layer, and use the weighing method to verify the coating rate (kg/m2 or L/m2) of each layer of paint . After the test piece is made, it is placed indoors for natural curing for 7 days

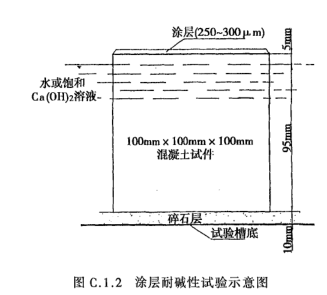

C.1.2.3 Alkali resistance test, take 3 test pieces, as shown in Figure C.1.2, with the paint coating facing up, half-immerse in water or saturated calcium hydroxide solution for 30d. During the test, check the appearance of the coating for blistering, cracking or peeling every 1 to 2 days.

C.1.2.4 Measure the total dry film thickness of the remaining 3 coating specimens with a microscope Thickness Gauge , and calculate the average thickness of at least 30 measuring points.

C.1,3 The test result report should include the following contents

(1) The name of the paint manufacturer;

(2) The names, grades and production batch numbers of various coatings;

(3) The coating rate of each coating (kg/m2 or L/m3);

(4) The maximum, minimum and average value of the dry film thickness;

(5) Description of the appearance state of the coating after the alkali resistance test.