What is the measurement principle of the gloss meter?

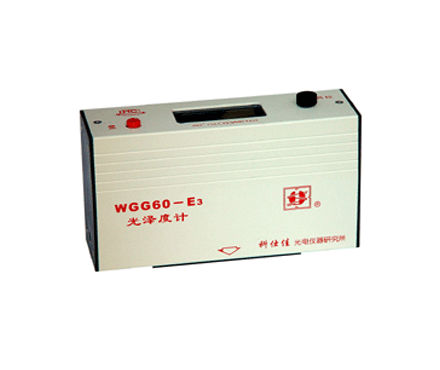

Gloss meter, also known as gloss meter, gloss Tester, etc., is an optical instrument specially used to check the surface gloss of objects, and is widely used in ceramics, paints, coatings, stone, electronics and other industries.

Gloss is a physical quantity that evaluates the ability of the surface of a material to reflect light under a set of geometrically specified conditions, and has a direction-selective reflection property. The gloss we usually refer to refers to "specular gloss", so the gloss meter is sometimes called "specular gloss meter". Therefore, to detect the surface gloss of an object, components such as a light source emitting device, a reflected light receiver, and a data analyzer are required. Let's take a look at the working principle of the gloss meter:

The light source G emits a beam of light through the lens L1 to the measured surface P, and the measured surface P reflects the light to the lens L2, and the lens L2 converges the light beam to the photocell located at the light bar B, and the photocell performs photoelectric conversion and sends the electrical signal to the The processing circuitry does the processing, and the instrument displays the measurement results. As shown below:

Under the specified light source and receiver opening angle conditions, the ratio of the radiated light energy (luminous flux) of the sample in the specular reflection direction to the reflected light energy (luminous flux) of the standard black glass sample in the specular reflection direction is the glossiness of the sample value. For polished black glass with a refractive index of 1.567, set its specular gloss value to 100 (gloss units) at a geometric angle of 60 degrees.

The main purpose and scope of application of the gloss meter

Gloss is a relatively common reference index in industry, such as metal processing, ceramic products, paint coatings, textile dyeing, etc., all have gloss requirements. Different industries have different standards for gloss. If there is no special regulation in the industry, we generally refer to different standards according to the angle of gloss measurement:

1. Reference standards for gloss Tester 20°: DIN-67530, ISO-2813, ASTM-D2457GB9754, GB8807, ISO-8254, ASTM-D523, which are mainly used for high-gloss ink, paint, paper, plastic, stone , Light casting coated paper and so on.

2. Reference standards for gloss Tester 45°: ISO-2767, GB8941.2, ASTM-D2457, ASTM-C346, GB8807, which are mainly used for the measurement of marble, ceramics, plastics, aluminum alloys and aluminum oxide surfaces, etc.

3. Reference standards for gloss Tester 60° ISO-2813, DIN-6750, ASTM-D2457, ASTM-C584, ASTM-D523, GB9754, GB8807, GB9966, which are mainly used for medium-gloss coated paper, marble, ceramics, Paints, inks, plastics and more.

4. The 85° gloss Tester is ISO-2813, DIN-67530, ASTM-D523GB9754, which is mainly used for camouflage coating, low gloss paint and so on.

Gloss can be divided into three types according to the measurement angle: high gloss, medium gloss and low gloss Tester. The gloss meter selected for different object surface gloss will be different. Generally speaking, the measurement angle of 20° is selected for high-gloss objects, the measurement angle of 60° is selected for medium-gloss objects, and the measurement angle of 85° is selected for low-gloss objects. Each range is best measured with its own angle. If you want to know which angle is more appropriate to measure, it is better to start with 60°. If the result is between 10-70GU, the coating can be called semi-gloss, preferably measured at this angle. If the result is less than 10GU, the product is called low gloss and should be measured at 85°; if the result is above 70GU, the product is high gloss and is better measured at 20°. All angles are calculated from vertical angles.

How to use the gloss meter?

The use methods of the gloss meter are similar, the main process and steps are power on, calibration, calibration, selection of measurement mode, and start of measurement. Due to the structure and components of different types of gloss meters, the accuracy will be different.

1. Turn on the instrument switch

Usually the power button of our gloss Tester is the measurement button, long press the measurement button to start it!

2. Calibration

1. If the standard board is dirty, please wipe the standard board with a special lens cloth, and then buckle the host into the base.

2. The host is not close to the standard board, please buckle it into the base again.

3. If there is a major change in the ambient temperature, the instrument temperature should be close to the ambient temperature, and after confirming that the lens in the test port of the instrument and the standard plate of the base have no condensation, restart the measurement.

Eliminate the above reasons, buckle the host into the base again, and the instrument will self-diagnose again. If the fault is eliminated, it will display "OK" and automatically enter the self-calibration mode.

3. Select the measurement mode

In order to cope with different usage environments, our gloss meter has a variety of modes, and you can choose according to your own needs.

4. Start measuring

The size of the measured sample should be larger than the measuring caliber of the gloss meter. If the surface has a certain curvature, a gloss meter with a smaller measuring caliber should be selected for testing.