0 Preface

Three-layer structure polyethylene layer (3PE) anti-corrosion technology has been widely used in the anti-corrosion engineering of buried long-distance pipelines in CHINA's petroleum industry and oil and gas field gathering pipelines, which has improved the level of CHINA's pipeline anti-corrosion technology, extended the service life of pipelines, and achieved good effect. Among them, the bottom layer of fusion bonded epoxy powder (FBE) is directly bonded to the surface of the steel pipe, and the adhesion between the two is one of the key indicators affecting the anticorrosion performance of steel pipes [1, 2].

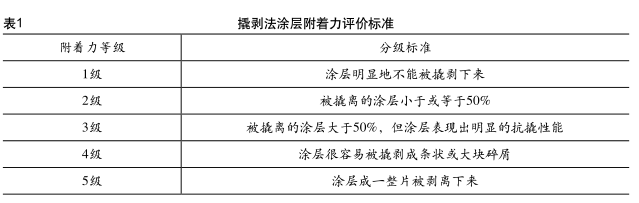

According to the survey, the current domestic and foreign relevant technical standards have adopted the method of prying and peeling rating for the inspection of coating adhesion performance, and the rating standards are basically the same [3-6], as shown in Table 1. It can be seen that this method is a simple grade judgment given by the Tester according to the description, which is a qualitative indicator , and the error caused by human factors is relatively large, which does not conform to the development trend of modern quality evaluation analysis automation and quantitative indicators. In this paper, method is used to evaluate the adhesion performance of FBE coatings, and compared with the method of prying and peeling rating, the test conditions and evaluation performance indicators for evaluating the adhesion of FBE coatings by the pull-out method are obtained.

1 Test method

1.1 Preparation of test piece

The bottom plate is a steel . After drying at 50 ℃ for 24 hours, it is cooled to room temperature in a desiccator . Coating thickness is (0.35±0.05) mm. Naturally cool to room temperature, and the number of test pieces in each group should be 3.

1.2 Prying and Peeling Rating Method

Refer to the relevant requirements in Appendix G of SY/T 0315-2013 "Technical Specifications for Fusion Bonded Epoxy Powder External Coatings for Steel Pipelines ". Take out the test piece after soaking and dry it. When the test piece is still warm, immediately use a knife to draw a rectangle of about 30mm×15mm on the coating, penetrate the coating to reach the base plate, and then cool it naturally in the air to 20°C ±3°C. Insert the tip of the knife under the coating from any corner of the rectangle within 1 hour after taking out the test piece, pry off the coating with a force in the horizontal direction, and push the tip of the knife continuously until all the coating in the rectangle is pried off or the coating shows Obvious prying performance . Evaluate the adhesion level of the rectangular inner coating according to the following grading standards .

1.3 Pulling method

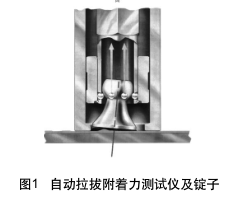

Referring to the relevant requirements in ASTM D4541-2017 "Pull-Off Adhesion Test" [7], the pull-off Tester is shown in Figure 1, and the adhesion test is carried out according to the following steps:

(1) Adhesive test column: An aluminum test column with a diameter of 10mm or 20mm should be selected , and the fully cured FBE coating surface to remove dust. Then, apply the prepared adhesive to the surface of the test column and the anti-corrosion layer, bond the test column and the anti-corrosion layer, and fully cure the adhesive according to the product instructions;

(2) Anti-corrosion layer cutting: After the adhesive is cured for 24 hours, use a matching ring-toothed cutter to perform circular cutting along the outer edge of the test column. It should cut through the anti-corrosion layer and reach the surface of the coated substrate, that is, the surface of the steel or the pipe body. Anti-corrosion layer surface. When cutting, avoid twisting the test column to prevent the bond between the cut circular coating and the substrate from being damaged;

(3) Place the test plate in a horizontal position, the test temperature should be controlled at (23±2)°C, and start the test after the automatic pull-off Tester is correctly connected ;

(4) Record the measured values of the three tests respectively, take the arithmetic mean as the test result, round the value to two significant figures, and report the damage type of the bonding surface.

2 Results and analysis

2.1 Coating adhesion changes at different immersion temperatures

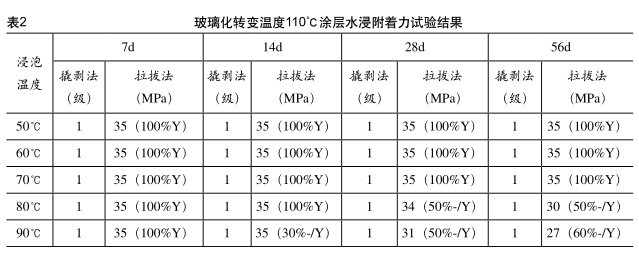

The immersion temperature was selected to be 50, 60, 70, 80, and 90 °C, and the water immersion adhesion carried out . The test results are shown in Table 2.

It can be seen that when the immersion temperature is below 80°C, after immersion for 56 days , the adhesion rating of the FBE coating by the peeling method is still level 1, and the adhesion by the pulling method is also maintained above 35MPa. There is no or slight discoloration on the surface of the coating. Change, indicating that the adhesion performance of the coating is good. When the immersion temperature reached 80°C, the adhesion rating of the prying method was still level 1 after 56 days, but the adhesion of the pulling method began to decline after 28 days of immersion , and the surface color of the coating was observed to be significantly lighter. When the soaking temperature was 90℃ , the downward trend began to appear at 14 days of soaking. It has been determined that the glass transition temperature of the wet film of the coating is 84.7°C. When the immersion close to or higher than this temperature, the coating structure begins to relax, resulting in a decrease in adhesion performance. Dissolution of inorganic substances [8, 9]. Comparing the two evaluation methods, it can be seen that the pulling method can intuitively reflect the performance change of FBE coating adhesion with the change of temperature and immersion time, and can comprehensively evaluate the coating adhesion effect [10].

2.2 Adhesion test of different types of FBE coatings

Four kinds of FBE coatings with different Tg were selected, and the water immersion adhesion test was carried out at a immersion temperature of 80 °C. The results are shown in Table 3.

It can be seen that the higher the Tg of the FBE coating, the better the adhesion performance ; when Tg=100℃, the coating surface was soaked for 7 days, the surface of the pull-out test coating appeared cemented failure, and at 14 days, the bottom plate and the coating appeared. Adhesive damage indicates that moisture has penetrated into the bottom plate, causing damage to the interface between the coating and the metal bottom plate; when the coating is immersed for 14 days at Tg=105°C, the coating surface begins to be cemented and damaged, and at 28 days, the coating is cohesively damaged; When Tg=110℃, cementation failure occurred on the surface of the coating after soaking for 28 days; when Tg=118℃, cementation failure did not begin to appear on the surface of the coating until the 56th day of soaking.

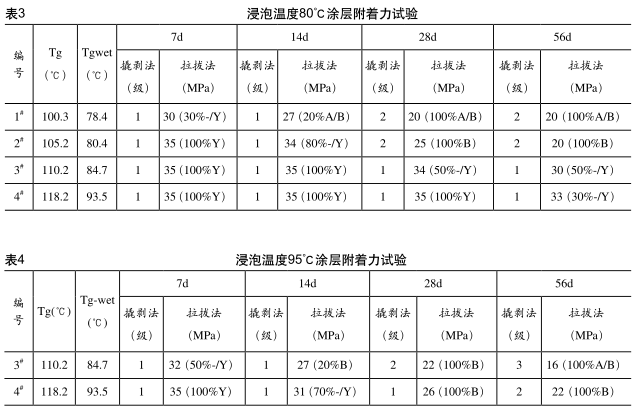

The 3 # and 4 # FBE coatings were selected for further water immersion adhesion test at a immersion temperature of 95°C, and the results are shown in Table 4.

It can be seen that when the coating was soaked at Tg=100℃ for 7 days, the surface of the coating began to be cemented and damaged, and at 14 days, the coating was cohesively damaged, and at 56 days, the coating and the base plate were damaged, and the prying method was rated as 3 ; =118°C, when the coating was immersed for 14 days, the surface cohesion failure , and the cohesive failure of the coating occurred after 28 days.

The above test conditions have verified the rationality of the Canadian standard CSA245.20-2014 dividing FBE coatings into low glass transition temperature (Tg< 115°C) coatings and high glass transition temperature (Tg>115°C) coatings . Combined with the comparison of the test results of the prying and peeling method, it is recommended to use the glass transition temperature of 115°C as the cut-off point to divide the FBE coating type, and the water immersion adhesion test conditions of the FBE coating with Tg≤115°C:

The immersion temperature is 80°C, the immersion time is 28d, the performance index of the drawing method is ≥20MPa; the FBE coating water immersion adhesion test conditions : the immersion temperature is 95°C, the immersion time is 28d, the performance index of the drawing method is Marked as ≥20MPa.

3 Conclusion

(1) The drawing method to evaluate the adhesion of FBE coatings has the advantages of being intuitive, quantitative , and can reflect the changing trend of coating adhesion;

(2) FBE drawing method adhesion evaluation test conditions:

FBE coating with Tg≤115℃: immersion temperature is 80℃, immersion time is 28d; FBE coating with Tg>115℃: immersion temperature is 95℃, immersion time is 28d. The performance evaluation index is ≥20MPa.