First, the instrument

1. Make sure that the host has been warmed up for at least 30 minutes before the test, that is, turn on the host for 30 minutes before the formal test , and use it after the Surface Tensiometer measurement system is stable.

2. According to the viscosity of the tested sample, set the correction value (that is, when the tension value of the platinum test plate touches the tested sample reaches this value, the lifting platform will automatically stop rising), the general empirical parameters are: low viscosity sample Set at 5.0; high viscosity samples set at 8.0. It can be set through the "Setting 1" and " Setting 2" buttons.

3. Before use, hang the attached hook and platinum plate on the hook, and press the "tare" button to return .

4. Make sure the platinum plate and glassware are clean before each test (very important). The specific method is:

(1) Under normal circumstances, wash the platinum plate with running water (preferably distilled water) first and then burn the platinum plate with an alcohol lamp. When the whole red (the time is about 20-30 seconds,) and hang it up for use (not time is too long to prevent the platinum plate from absorbing moisture). If the test sample was oily in the last experiment, using special degreasing solvent to clean the platinum sheet can ensure a good cleaning effect.

(2) The glass dish should be cleaned and dried before the test. During the test, a small amount of the sample to be tested should be taken to pre-wet the glass dish to maintain the validity of the measured data.

(3) Please do not contact the platinum plate with any liquid before it cools down, so as not to affect .

5. If temperature control is required, please purchase additional constant temperature control equipment.

6. Full-scale calibration of the tensiometer can be performed after the first use or after a period of use:

(1) Hang the hook and the platinum plate.

(2) Press "Tare" to display 0.0mN/m, 0.00mN/m, 0.000mN/m.

(3) Press the "calibration" button, "CAL" is displayed, and hang the standard weight attached to it.

(4) "600.0mN/m" (400.00mN/m, 200.000 mN/m) will appear in about 5 seconds, and the calibration will end after hearing the sound of "beep".

(5) Take off the standard weight, and the display screen should return to zero; if it does not return to zero, it should be calibrated again.

Second, the testing process:

1. When the platinum plate or glass dish is not clean, there will be some errors in the measured value, and the reproducibility is poor, the value fluctuates or continuously increases or decreases, so try to keep it clean. For example, if the user taps the water with his finger in the process of water measurement, the instrument will immediately display a changed smaller tension value. This is because the human hand has oil, which changes the surface of the water. characteristic.

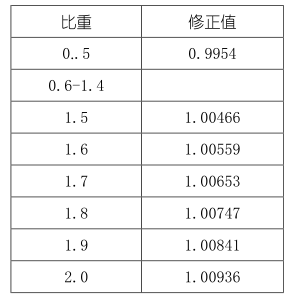

2. The instrument has made certain corrections to the density. If you need to ensure that the test results are more accurate, please refer to the correction table in the attachment to make corrections.

3. In order to meet the test accuracy requirements, the platinum plates of our company are all specially ordered, and the surface is treated with special roughness. Therefore, scratches and abrasions indicated by platinum plates should be avoided. If the user replaces it and cannot measure accurately, the company will not be responsible for it.

4. According to the physical and chemical principles, in fact, the natural conditions that affect the measured value during the test are (1) temperature; (2) air pressure.

5. Generally speaking, the surface tension of liquid decreases with the increase of temperature. Therefore, if you are very concerned it is recommended that you purchase a constant temperature bath produced by our factory with a temperature control accuracy of 0.1°C and a cooling function, and a sample constant temperature pool that can keep the tested sample warm.

6. When measuring highly volatile liquids, the test process should be accelerated. Highly volatile liquids are easy to stick to the platinum plate during measurement . Please clean the platinum plate before repeating the test.

7. When evaporation occurs during measurement, the surface tension value will increase with time.

8. Although the amount of the measured liquid in the glass dish will not affect the accuracy of the measured value, for the sake of safety , please ensure that the liquid has a height of 5mm, about 15ml.

9. When adding surfactant to observe the change of surface tension, please make sure not to touch the platinum plate with the surfactant.

10. The rise or fall of the sample stage during the measurement process will affect the surface tension value, which decreases and increases when it falls. Both are one of the manifestations of error.

Troubleshooting

First, the value is low:

1. The platinum plate is not cleaned (very likely);

2. Zeroing is not fully completed;

3. The glassware has not been rinsed clean, for example, it contains residual substances from the previous test;

4. Oil on hands contaminates the sample to be tested;

5. The measured liquid itself is an active agent or a mixture, and its characteristics change with time.

Therefore, it should be ensured that the mixing is even and the ratio is the same, and it is better to test after standing still for the same time.

6. The wettability of the measured liquid is not very high or viscous and volatile.

Second, the value is too high:

1. Inaccurate zeroing;

2. The measured liquid itself is an active agent or a mixture, and its characteristics change with time.

Therefore, it should be ensured that the mixing is even and the ratio is the same, and it is better to test after standing still for the same time.

3. The tested sample has viscosity.

Third, poor repeatability:

1. The platinum plate is not completely cleaned;

2. The tested sample itself changes with time (adding surfactant);

Fourth, the abnormal display value:

1. The internal data connection line is not connected properly;

2. The instrument failure needs to be repaired;

Fifth, the automatic test cannot be carried out:

1. If the displayed tension value is greater than the set value, please perform tare operation

2. The viscosity is high, please operate according to the measurement method of high viscosity samples;

3. The surface tension value of the sample is small, please reduce the setting value of the automatic stop part;

4. After the platinum plate is pre-wetted, its display value is greater than the set value.

Test Methods

Standard test method: (commonly used)

It is very simple to use this instrument to measure data. Since this instrument is very sensitive to the value, it has certain requirements for cleanliness and temperature during the test process. Please strictly follow the precautions to ensure that the human error in the test process is minimized.

The test steps are as follows:

The first step, turn on the instrument:

Turn on the power of the Surface Tensiometer, hang the hook and the platinum plate, and press the "ON/OFF" button to preheat for 30 minutes.

The second step is to clean the platinum plate, the steps are:

1. Pick up the platinum plate with tweezers and rinse it with running water. When rinsing, pay attention to maintaining a certain angle with the water flow. The principle is to let the water flow clean the surface of the plate as much as possible and not let the water flow deform the plate;

2、用酒精灯烧白金板,一般为与水平面呈45度角进行,直到白金板变红为止,时间为15-25秒。

3、注意事项:通常情况为用水清洗即可,但遇有机液体或其他污染物用水无法清洗时请用丙酮清洗或用20%HCL加热十五分钟进行清洗。然后再用水冲洗,烧红即可。

第三步、在样品皿中加入测量液体,将被测样品放于样品台上。放之前请一定目测一下白金板挂的高度,如果可能会浸入样品中时,请将按“向下”按键,将样品台向下。(注:在取样时,更好用移液管从待测液中部取样,并确保在取样前样品皿的干净度)

第四步、观察液晶屏显示值是否是零。如果不是零,则请按“去皮”按键。作清零处理。准备就绪后,

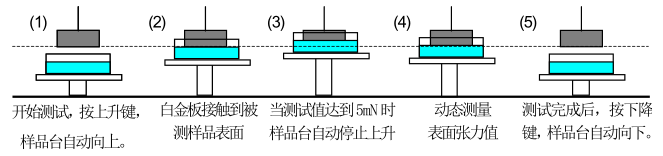

第五步、观察“手动/自动”按键处指示灯指示情况。如果是自动的,指示灯亮的;如果是手动,那么灯是暗的。请按动“手动/自动”按键,将表面张力仪调至自动状态。处于自动状态时,如上升期间白金板碰到被测试样,且张力值达到修正值设定的数字(比如5mN),升降平台会自

动停下,如下降时则会过15秒后自动停下(再按下降键时会再过15秒后自动停下)。

处于手动状态时, 上升期间与自动状态一样;下降时则一直到最低点停下。

第六步、按“向上键”自动测试表面张力, 待显示屏的数值稳定后可以读取液晶显示屏上的表面张力值。由于本仪器感测到的值是动态表面张力值。如果样品是单纯一种物质的话,那么表面张力值将会是稳定的。(假设温试变化不大的情况下)。

注意:如果被测样品中含有表面活性剂或被测样品为混合物时,表面张力值会出现一定的变化,且出现最终稳定值的时间会因样品的不同而不同。

此时您如何取值应According to实际应用要求而定。

第七步、完成测试。您可以按“向下”按键完成一次测值过程。如果您想重复测值,则请按如下方法执行。

第八步、重复性操作的方法为:按“向下”按键,表面张力仪升降样品台逐渐下降,白金板脱离被测样品后,可先按“停止”按键,然后再重新按“向上”按键进行测试,测得值后您就可以分析重复性效果。

注意,作重复性操作时,一定不用去理会表面张力仪显示出的残留数值,即不注意,作重复性操作时,一定不用去理会表面张力仪显示出的残留数值,即不要做去皮动作。一般情况下,如果这个值m超过5mN/m时才会要求重新清洗白金板。

整个测试过程如下图示意:

附件:修正表:

如果您对测量的结果精度要求很高,请按如下修正表进行修正:

中高粘度液体的测量:

此方法是应用在测量中粘度高于500CP.S之液体,测量时间超过5分钟,其测量值才会达到稳定(不包括液体本身随时间而变化的性质)例如甘油、粘胶等。

方法一、手动方式:

(1)挂上白金板并归零;

(2)将表面张力仪“手动/自动”调至手动状态。即指示灯不亮;

(3)按照下列步骤使样品台上升到接触到白金板:

A按“向上”按键,使得样品上升。

B等到白金板快刚接触到样品表面时,按“停止”按键。停止样品台的上升。等停止后,白金板应该是接触到样品表面,并且液晶屏显示出的表面张力值是负值。注意,这个接触到的高度即白金板插入样品深约为1mm左右(实际上由于试样的粘度高,白金板开始接触样品时并不能真正插入而是被样品托起)。

(4)取下白金板并润湿5mm高度(不能太高,且如果挂上后显示值超过5mN/m时,请将白金板在样品表面轻刮去直到显示值小于5mN/m)

(5)重新挂上白金板,此时样品会接触到白金板,并出现表面张力现象,完成润湿的过程。

(6)等相对稳定时记取读数。

方法二、自动操作:

我们建议客户利用此方法进行操作,但如果对时间要求较高,请按第三种方法进行测试。

(1)挂上白金板并且归零;

(2)取下白金板并润湿5mm高度;

(3)利用面纸轻轻将粘着在白金板上的液体擦掉一些;

(4)重新挂上白金板,此时显示值会大于0,请不要归零,如果显示值大于5mN/m时,请再擦去一些;

(5)按“向上”按键进行测试,记取稳定值;

方法三、手动操作/快速测量:

如方法一1-4,使用外力将白金板浸入液体使其值接近液体表面张力,如液体表面张力为25时,让白金板浸入液体并显示值为23-24左右。利用此方法可很容易测出高粘度表面张力且缩短时间。

测量表面活性剂

表面活性剂的表面张力较为特殊,纯表面活性剂加入其他液体中后,样品的表面张力值会随时间的变化而变化。在加入不同量的表面活性剂时,样品的表面张力会出现不同的值,但通常情况会出现一个临界值,即为CMC。

具体请参考相关资料。本仪器可以很容易的完成随时间变化而变化的表面张力值的测量。

1)准备测量(预热、清洗、配样等)

2)将样品倒入玻璃皿中大约80%的高度;

3)倒出1/3的样品以产生新的表面;

4)如标准测量法中一样测量表面张力值,并观察表面张力的变化曲线情况。

通常视客户要求,取某个时间点作为一个稳定的参考表面张力值。

注意事项:

1)According to我们的经验,每个行业对时间的取法会不同;

2)使用者更好使用摩尔量来配制样品,并且取不同的摩尔量的样品,以观察CMC值。同时也可采用如下方法测得CMC值,但需要客户手工通过软件计算摩尔量。我们的仪器可以显示出表面张力变化的拐点所在。

取一定量的水,加入很小量的表面活性剂,然后每次加入同样量的表面活性剂,直到出现拐点为止。当然这个量的多少According to客户的样品而定。

3)当测量低浓度表面活性剂时,表面张力值会随着附着在液体表面的界面活性剂的多少而改变,由于表面状态一直在变,其值比较不稳定,但是当表面的界面活性剂达到平衡后,其值就会相对稳定。有时候这个过程需要4-5小时。

测量界面张力的方法

测量界面张力比测量表面张力时更需要注意白金板的清洁度问题。

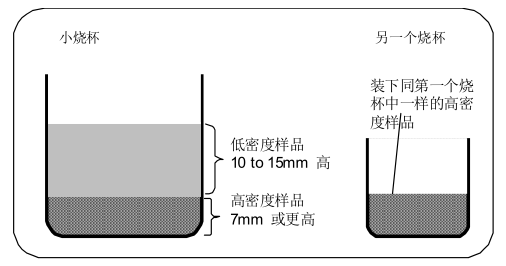

方法一、测量样品A的比重>样品B时的界面张力(如:水-苯、水-油等)

1)使用较高的玻璃皿,建议采用比色皿,并将样品A倒入烧杯中高度约7mm(或更高)。

2)将样品B倒入玻璃皿内约15mm。

3)将样品放到样品台上。

4)取少量样品A倒入另外的玻璃皿内。等完成所有测试准备后,将白金板浸入样品A大约10mm,并以一个倾斜角度使白金板离开液面。

5)将白金板挂到挂钩上,并确保白金板停留在样品B中同时不接触到样品A。如果接触到样品A,请清洗后,重新开始直到实现本目标。

6)将仪器的触动张力设置为0.3mN/m。

7) Press the "tare" button, and the displayed value will return to zero. (The value is the buoyancy of the platinum plate) Then press the "up" button to test, and take the value after it stabilizes.

Method 2. This method is suitable for samples whose interfacial tension is lower than 5mN/m.

1) Steps 1-6 are the same as method one; then press the reset key to reset the display to zero.

2) Lift the sample stage manually until the platinum plate touches sample A;

3) Manually lower the sample stage, read the gradually increasing surface tension value, and use the following formula to calculate after obtaining the maximum value: maximum value * 0.991 = measured value.