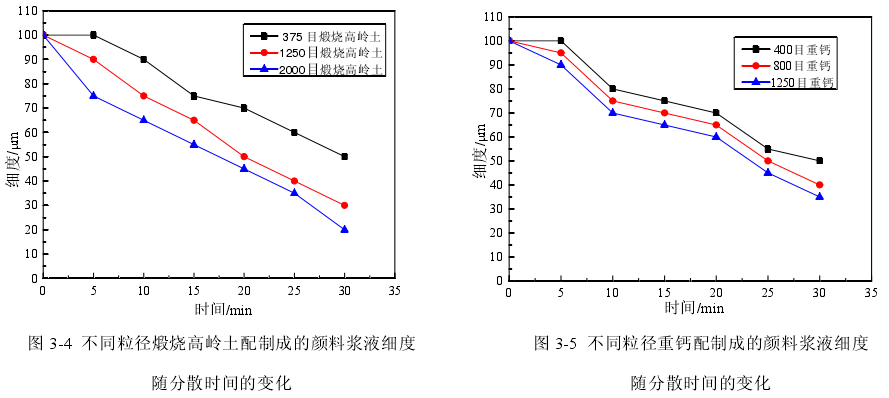

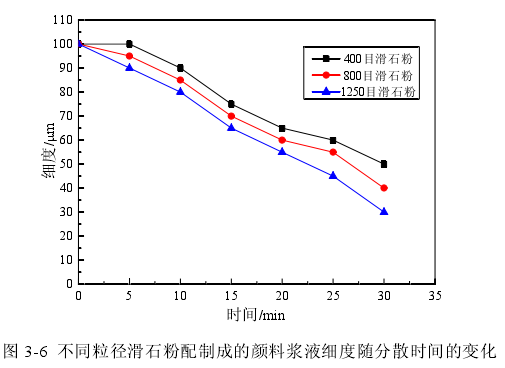

In order to investigate the effect of filler particle size on the fineness of latex paint pigment slurry, 375 mesh, 1250 mesh, 2000 mesh calcined kaolin; 400 mesh, 800 mesh, 1250 mesh heavy calcium; 400 mesh, 800 mesh, 1250 mesh talcum powder were selected as filler. The amount of filler is 15% of the total mass of the latex paint, the stirring speed is 1500r/min, and the pigment is 25% rutile titanium dioxide. The fineness of latex paint pigment slurry is tested according to the scraper Fineness Meter method stipulated in the national standard GB/T 6753.1-1988, and the results are shown in Figure 3-4, Figure 3-5, and Figure 3-6.

It can be seen from Figure 3-4 that when 375 mesh, 1250 mesh, and 2000 mesh calcined kaolin were used as fillers, the fineness of the pigment slurry was 75µm, 65µm, and 55µm when the dispersion time was 15 minutes; when the dispersion time was 30 minutes, the slurry fineness The degrees are 50µm, 30µm, and 20µm, respectively. It can be seen from Figure 3-5 that when 400 mesh, 800 mesh, and 1250 mesh heavy calcium are used as fillers, when the dispersion time is 15 minutes, the fineness of the pigment slurry is 75 µm, 70 µm, and 65 µm; when the dispersion time is 30 minutes, the fineness of the slurry is respectively 50µm, 40µm, 35µm. It can be seen from Figure 3-6 that when 400 mesh, 800 mesh, and 1250 mesh talc powder are used as fillers, the fineness of the pigment slurry is 75µm, 70µm, and 65µm when the dispersion time is 15min; when the dispersion time is 30min, the slurry fineness They are 50µm, 40µm, and 30µm, respectively. It can be seen from Fig. 3-4, Fig. 3-5 and Fig. 3-6 that as the particle size of the filler decreases, the fineness of the pigment slurry prepared by it can be achieved within the same dispersion time. Smaller, the shorter the dispersion time required to reach the specified fineness. This is because the smaller the particle size of the filler, the easier it is to disperse evenly under the action of mechanical stirring. Therefore, the selection of fillers with smaller particle sizes is conducive to shortening the production cycle of latex paint. However, if the particle size of the filler is too small, the agglomeration force increases rapidly, and it is easy to aggregate to form sedimentation, and the cost is high; the particle size of the filler is too large, it is not easy to disperse evenly in the latex paint slurry, which will increase the sedimentation velocity of the latex paint. Thereby accelerating the occurrence of subsidence and water separation [66]. Therefore, the selection of filler particle size should also be determined according to the actual situation. At present, 1250 mesh fillers are generally used in the production of latex paint.