Powder coatings are increasingly popular due to their superior mechanical properties and solvent-free properties. After the coating surface is powder coated, it not only has a high-quality appearance, but also has a variety of functional properties, including corrosion resistance and electrical insulation. The key is to control the film thickness of the powder coating within the specified range to achieve these performance.

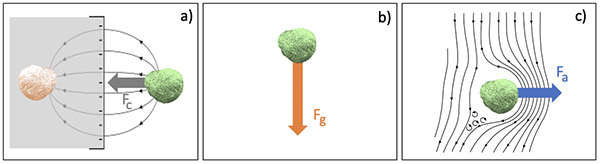

For parts with complex shapes such as unevenness or bending, it is undoubtedly a technical challenge for most paint shops to accurately measure the coating thickness and control it within the acceptable range. During powder coating, there are three main physical effects that affect the movement of powder particles: electrostatic force, aerodynamic force and gravity. Among them, the influence of electrostatic force and gravity on powder particles is easy to understand, but the interaction of physics and aerodynamics is very complicated. This article will describe the difference that powder coating can make on sharp edges.

(Figure 1: The physical effects that mainly affect powder coatings include: a electrostatic force, b gravity, c aerodynamic force)

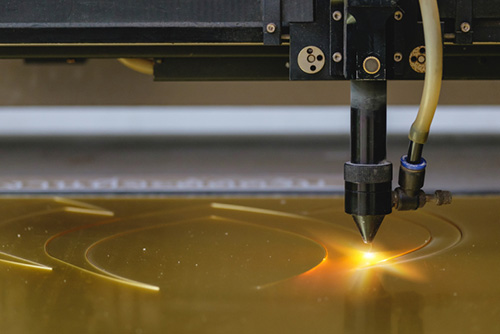

Even if the product is coated, the sharp edges are still weak points for corrosion protection and electrical insulation, because it is difficult for the powder to form a sufficient film thickness on the sharp edges. Sharp edges are usually produced by mechanical or laser cutting of sheet metal parts. If the sharp edges are rounded by sandblasting or grinding, the problem of poor coating coverage can be effectively solved. When the powder coating is softened by high temperature, the coating at the edge shrinks due to surface tension, and the coating flows out from the edge. Therefore, the film thickness at the edge will be lower than the lower limit of the acceptable film thickness range.

Figure 2: Laser cutting sheet metal parts will form sharp edges, and effective means should be taken to increase their curvature radius before painting.

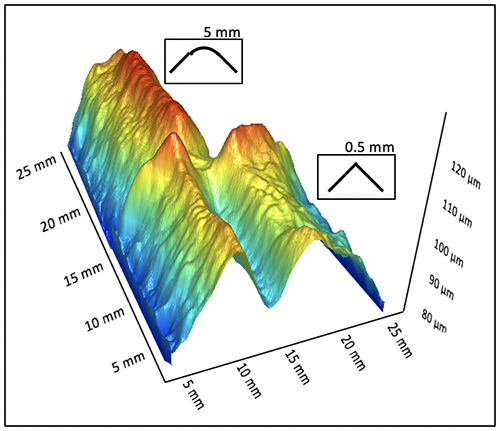

A new study now shows that the thickness of the edge coating before drying is lower than the typical estimated film thickness. In the research experiment, two substrates with different radii of curvature (5mm and 0.5mm) were simultaneously powder-coated (RAL 2008, smooth finish). First place the high-pressure Spray Gun at a distance of 50 cm from the object, set the voltage at 50 kV and deliver the air flow at xx l/min, and then carry out powder coating. Before the coating is cured, use the coatmaster 3D non-contact imaging thickness measurement system to measure the coating thickness, and finally obtain the film thickness distribution image of the entire sample. The film thickness distribution image area is 25 mm x 25 mm with a spatial resolution of 100 µm.

Figure 3: Using the coatmaster 3D Atline non-contact imaging thickness measurement system to record the coating thickness distribution of substrates with different curvature radii

From the coatmaster 3D Atline film thickness distribution diagram (Figure 3), it can be seen that the second half is the coating thickness distribution of the substrate with a radius of curvature of 5mm, and the coating thickness in the edge area is about 40% thicker. In another case, for a substrate with a radius of curvature of 0.5mm at the edge, the coating thickness in the edge area is about 20% lower than that in the peripheral area.

The high coating thickness on the rounded edge is due to the electrostatic effect between the Spray Gun and the grounded part. The charged powder particles are accelerated along the electric field lines, reach the edge and settle down. For the sharp edge coating thickness is too small, in addition to being affected by electrostatic force, aerodynamic force is the main influencing factor. As air flows around a sharp edge, the airflow separates itself, creating a pronounced area of low pressure. According to the Bernoulli effect, this is associated with a significantly faster flow velocity at the edges. Therefore, the aerodynamic force is greater than the electrostatic force near the sharp edge, and the powder particles do not settle on the substrate.

In addition to marginal factors, fluid mechanics is also the main reason for the formation of weak spots in powder coating corrosion protection and electrical insulation. A study is currently underway to optimize the flow of functional powder coatings, considering that the coating material can either flow away from the edge (classical edge alignment) or flow towards the edge (edge feed). The 3D imaging coating thickness measurement technology plays an important role in the development of coating materials. It can effectively help improve the problem of coating materials covering the edges, thereby improving the corrosion protection and electrical insulation of coating materials.