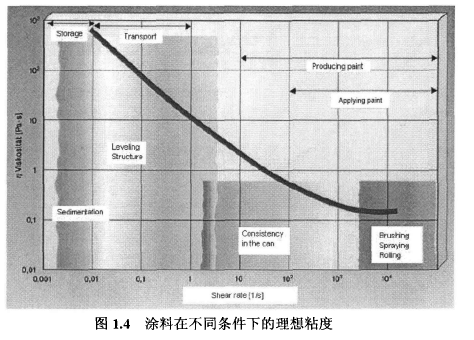

Chin white pulp is a semi-finished product in the paint production process. Like paint, it will experience different shear rates in different situations. According to our actual production and use conditions, we hope that it can have different viscosities in different stages . , For example, in the storage process, we hope that the paint has a relatively high viscosity to prevent the pigment from settling during the production process, and we also need it to have good fluidity for easy pumping, so this also puts forward higher requirements for us , the same white paste should show different viscosities under different conditions, which seems impossible task, but if we combine the shear rate and viscosity of the coating at different stages, the problem will become very simple . The figure can also reflect the variation of the viscosity of the slurry with the shear rate.

From the above description, we found that the rheological properties of the slurry clearly characterize the sedimentation behavior of the pigment suspension, reflecting the stability of the colorant in the macroscopic sense, but what will be the result of the anti-coarseness and flocculation of the pigment? The dispersed pigment White powder, flocculation occurs due to the interaction between particles, thus forming a loose network structure. This structure will have a certain influence on the rheology of the slurry. Because of this weak network structure, it can prevent the movement between the white particles , thereby When the rate is high, it can be easily destroyed, so that the viscosity of the slurry can rapidly, but when the stirring is stopped, the viscosity can also be recovered correspondingly due to the recovery of the network structure. We call this state thixotropy. Figure 1.5 is a good example

Figure 1.5 is a shear rate sweep of a thixotropic additive coating. It can be clearly seen from the figure that under the same shear rate, the viscosity measured by the shear rate rising scan is completely different from that of the descending scan. That's because the paint is doing

During the scanning process of rising shear rate, the structure damage caused by the shearing of the paint cannot be recovered in a short time, so the viscosity is obviously smaller when scanning downward.

The technology of thixotropic behavior is rather complex. We usually use the area surrounded by the viscosity curve or stress curve , and judge the thixotropy of the coating by calculating the area of the thixotropic ring.

At present, judging the flocculation between pigment particles and the stability of color paste based on the thixotropy of the paste has been recognized by many additive companies.