Adjustable Film Applicators are becoming more and more popular with laboratory personnel not because they are more accurate than wire rods or wet film preparers, but because they are "adjustable". Regardless of whether it is imported or domestically produced, most of the adjustable Film Applicators on the market use a differentiator to adjust the height of the scraper, or use an electronic display to adjust. But the principle is the same.

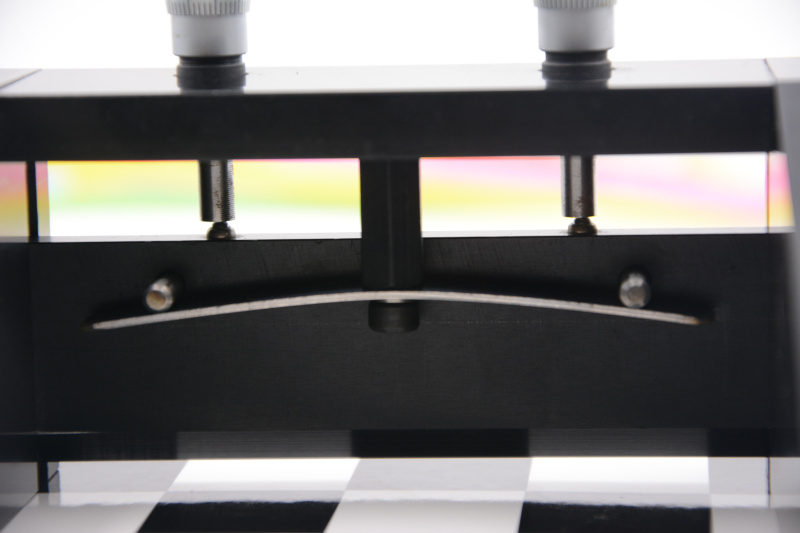

The following is a real shot of the adjustable Film Applicator taken by NBCHAO, and it is presented to everyone from all angles:

There is a requirement for the thickness control of the adjustable Film Applicator, that is, the bottom surface needs to be flat, because all adjustable Film Applicators rely on the contact at both ends to maintain the height of the middle scraper. Therefore, it is not suitable for the preparation of glass slides and small samples. For this, choose a wire rod. But the advantage of the adjustable type is that you can do whatever you want for the film formation of hundreds of microns or even thousands of microns.