The UTG-1500 is a professional lightweight ultrasonic Thickness Gauge designed for ease of use and ruggedness for use in harsh environments.

Utilizing new microcomputer circuitry, the device offers a combination of high precision and fast measurement times.

Offers wide measurement range and high resolution.

Any material capable of transmitting sound waves can be measured as long as the object has parallel top and bottom surfaces.

calibration

1) Place a small drop of coupling gel on the No. 12 calibration block at the bottom of the gage.

2) Press the calibration key #8, "cal" will flash on the display.

3) Press the #7 probe on the #12 calibration block and make sure the coupling indicator appears on the display. The reading should be 0.197 inches (5 mm). This will flash "cal". Press CAL to save while holding the probe on the module. Remove the probes from the module. Press the probe against the test block again to confirm the reading is approx. 0.197 inches.

4) After confirmation, the calibration result will be saved automatically. This process lets you know that the unit is functioning properly. Now is the time to set up the UTG-1500 to read your parts/materials correctly.

material selection

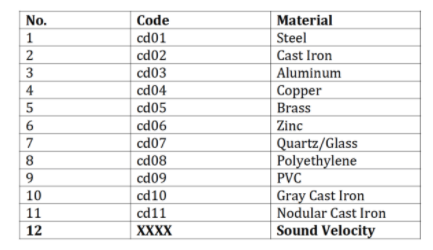

1) Press the "Select" button to enter the material selection state, then press the + button to choose from 11 commonly used materials. See the diagram below for a bill of materials. When you switch through the material selection process, the display will only show the code (cd01). Press the Select button to confirm the selection.

measurement procedure

1) Press the power switch to turn on the device

2) Press the IN/MM button to set inches/mm

3) Put a drop of gel on the surface to be tested and place the probe directly into the gel. The reading on the display is the actual thickness of the part being tested.

4) The last reading will remain on the display until the unit is powered off.

thickness measurement

This pressure gauge is capable of measuring a wide variety of materials from various metals to glass and plastics. However, different types of materials will require the use of different transducers. The importance of choosing the right sensor for the job to be able to easily perform accurate and reliable measurements cannot be overemphasized. The following paragraphs highlight important transducer characteristics that should be considered when selecting a transducer for a specific job. In general, the right transducer for the job is one that sends enough ultrasonic energy into the material being measured that a strong, steady echo is received by the gauge. Several factors affect the strength of ultrasonic transmission.

initial signal strength

开始的信号越强,其返回回波将越强。初始信号强度在很大程度上是换能器中超声发射器尺寸的一个因素。与小发射面积相比,大的发射面积将向被测材料发送更多的能量。因此,所谓的“ 1/2英寸”传感器将比“ 1/4英寸”传感器发出更强的信号。

吸收和散射

当超声波穿过任何材料时,它会被部分吸收。如果声音传播的材料具有任何颗粒结构,则声波将经历散射。这两种影响都降低了波的强度,从而降低了仪表检测回波的能力。高频超声比低频超声吸收和散射更多。尽管在每种情况下似乎都使用低频换能器可能会更好,但低频的指向性要比高频小。因此,较高的换能器将是检测被测材料中小凹坑或缺陷的准确位置的更好选择。

换能器的几何形状

测量环境的物理限制有时会确定换能器对给定工作的适用性。一些换能器可能太大而不能在狭窄的区域中使用。同样,可用于与换能器接触的表面积可能会受到限制,需要使用磨损面小的换能器。在曲面(例如发动机汽缸壁)上进行测量可能需要使用具有匹配曲面磨损面的传感器。

材料温度

当需要在过热的表面上进行测量时,需要使用高温传感器。这些换能器使用特殊的材料和技术制成,可使其承受高温而不会损坏。另外,用高温传感器执行“探针零”或“校准至已知厚度”时需要小心。

选择合适的传感器通常是各种特性之间的权衡问题。可能有必要对各种换能器进行实验,以找到适合特定工作的换能器。传感器是仪器的“业务端”。它发送和接收超声波,仪器使用超声波来计算被测材料的厚度。传感器通过附带的电缆和两个同轴连接器连接到仪器。使用换能器时,双同轴连接器的方向并不重要:两个插头都可以安装到仪器的两个插座中。需要正确使用传感器,才能使仪器产生准确,可靠的测量结果。以下是换能器的简短说明,并附有使用说明。

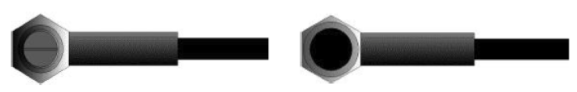

左上方是典型测厚传感器的底视图。可以看到磨损面的两个半圆,也可以看到分隔它们的障碍物。一个半圆负责将超声波传导到被测材料中,另一个半圆负责将回声传导回换能器中。当传感器紧靠被测材料放置时,就是被测磨损面中心正下方的区域。右图是典型传感器的俯视图。用拇指或食指顶住传感器,将其固定在适当的位置。适度的压力就足够了,因为仅需保持传感器保持静止,且耐磨面应平放在被测材料的表面上。

表面的条件和准备

在任何超声测量情况下,测试表面的形状和粗糙度都其重要性不言而喻。粗糙,不平坦的表面可能会限制超声穿透材料的穿透力,并导致测量不稳定,因此不可靠。被测表面应清洁,无任何细小颗粒,铁锈或水垢。此类障碍物的存在将阻止传感器正确靠在表面上。通常,钢丝刷或刮刀将有助于清洁表面。在更极端的情况下,可以使用旋转砂光机或砂轮,但需要注意防止表面气刨,这会妨碍传感器正确耦合。

非常粗糙的表面,例如某些铸铁的卵石状表面,将证明最难测量。这些类型的表面像光束上的磨砂玻璃一样作用在声束上,声束在各个方向上扩散和散射。

除了对测量造成障碍之外,粗糙表面还会导致传感器过度磨损,特别是在传感器沿表面“擦洗”的情况下。应定期检查传感器,看是否有磨损面不均匀磨损的迹象。如果耐磨面的磨损程度大于一侧,则穿透测试材料的声束可能不再垂直于材料表面。在他的情况下,由于声束的焦点不再直接位于传感器下方,将很难在被测材料中精准定位微小的不规则之处。

重要提示

当工具显示厚度测量值时,显示屏将保留最后一次测量的值,直到进行新的测量为止。为了使换能器正常工作,在磨损面和被测材料的表面之间需要没有气隙。这可以通过使用通常称为“耦合剂”的“耦合”流体来实现。该流体用于将来自传感器的超声波“耦合”或传输到材料中,然后再返回。在尝试进行测量之前,应将少量的耦合剂涂在被测材料的表面。通常,一滴耦合剂就足够了。

施加耦合剂后,将传感器(磨损面朝下)用力按在要测量的区域上。耦合状态指示器应出现,并且显示屏上将出现数字。如果已将超声波测厚仪正确“调零”并设置为正确的声速,则显示屏中的数字将指示传感器正下方的材料的实际厚度。

如果耦合状态指示器看起来不稳定,或者显示屏上的数字似乎不稳定,请检查以确保测厚探头下方有足够的耦合剂薄膜,并且传感器平放在材料上。如果情况仍然存在,则可能有必要为被测材料选择不同的传感器(尺寸或频率)。

当测厚探头与被测材料接触时,仪器将每秒执行四次测量,并以此更新其显示。从表面移开传感器后,显示屏将保留上一次进行的测量。

注意

有时,在移除换能器时,会在传感器和表面之间拉出一小片耦合剂薄膜。发生这种情况时,量规可能会通过该耦合剂薄膜进行测量,从而导致测量结果大于或小于应有的大小。当在传感器就位时观察到一个厚度值,而在取下传感器后观察到另一个厚度值时,这种现象很明显。另外,通过非常厚的油漆或涂料进行的测量可能会导致油漆或涂料的测量而不是实际的预期材料。正确使用仪器以及识别此类现象的责任完全由仪器使用者承担。

测量管材

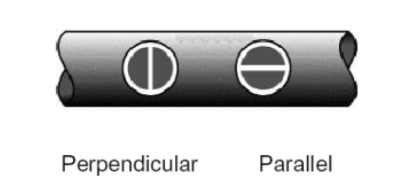

在测量一段管道以确定管道壁的厚度时,传感器的方向很重要。如果管道的直径大于约4英寸,则应在传感器定向后进行测量,以使磨损面中的间隙垂直于管道的长轴(成直角)。对于较小的管道直径,应进行两次测量,一次测量的磨损面间隙垂直,另一次的测量间隙平行于管道的长轴。然后,应将两个显示值中较小的一个作为该点的厚度。

测量热表面

通过物质的声速取决于其温度。随着材料的加热,通过它们的声音速度会降低。在大多数表面温度低于约100的应用中,无需遵守特殊程序。在高于此温度的温度下,被测材料的声速变化开始对超声波测量产生明显影响。在这样的高温下,建议用户对已知厚度的样品进行校准程序,该样品处于或接近被测材料的温度。这将使量规正确计算通过热材料的声速。

在高温表面上进行测量时,可能还需要使用特殊构造的高温传感器。这些传感器是使用可以承受高温的材料制成的。即使这样,建议将探头与表面接触的时间尽可能短,以获取稳定的测量结果。当传感器与高温表面接触时,它将开始加热,并且由于热膨胀和其他影响,可能开始对测量精度产生不利影响。

测量层压材料

Laminates are unique in that their density (and thus the speed of sound) can vary greatly from one piece to the next. Some laminates may even exhibit significant variations in sound velocity across a single surface. A separate method to reliably measure such materials is to perform a calibration procedure on samples of known thickness. Desirably, this sample material should be part of the same piece to be measured, or at least part of the same batch of laminated material. By calibrating each test piece individually, the effect of variations in sound velocity can be minimized.

Another important consideration when measuring laminates is that any contained air gaps or pockets will cause early reflections of the ultrasound beam. This effect is noticed in cases where the thickness of an otherwise regular surface suddenly decreases. While this may prevent accurate measurements of total material thickness, it does provide the user with a positive indication of air gaps in the laminate.

material suitability

Ultrasonic thickness measurement depends on the passage of sound waves through the material being measured. Not all materials are good at transmitting sound. Ultrasonic thickness measurement works on a wide variety of materials including metals, plastics and glass. Difficult materials include some cast materials, concrete, wood, fiberglass, and some rubber.

Coupling agent

All ultrasound applications require some sort of medium to couple the sound from the transducer to the test piece. Usually, a high viscosity liquid is used as the medium. The sound used in ultrasonic thickness measurement does not travel efficiently through air.

A variety of couplant materials can be used in ultrasonic measurements. Propylene glycol is suitable for most applications. In difficult applications where maximum acoustic energy transfer is required, glycerin is recommended. However, on some metals, glycerol can promote corrosion by absorbing water and thus may be undesirable.

Other suitable couplants for measurements at ambient temperatures may include water, various greases, gels, and silicone oils. Measurements at high temperatures will require specially formulated high temperature couplants.

In standard pulse-echo mode, the instrument may use the second echo from the backside of the material being measured instead of the first echo, which is inherent in ultrasonic thickness measurements. This can cause thickness readings to be twice as high as they should be. The responsibility for the correct use of the instrument and the recognition of such phenomena rests entirely with the user of the instrument.

maintainance

Replacement battery

After the low battery indicator appears on the screen, the batteries should be replaced.

When replacing the battery, follow the steps below. Turn off the power or wait for the power to turn off automatically. Open the battery compartment. Remove the used battery and insert the new battery into the compartment, paying close attention to the polarity of the battery.