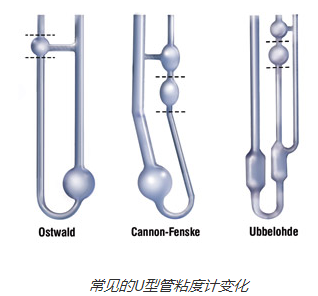

The main piece of equipment used in capillary viscometer testing is the generally "U" shaped glass tube, which gives it its common name, the U-tube. The U-tube procedure requires immersion of the tube in a temperature-controlled bath (typically 40 or 100 degrees Celsius) and a certain precise time readout (in seconds) to ensure that a certain amount of fluid flows through the tube . Move the tube from one marked point to another by suction or gravity.

This measured time is then multiplied by a constant (relative to the particular tube) to calculate absolute viscosity (suction) or kinematic viscosity (gravity).

Factors Affecting Viscosity Measurements

Although the viscosity of a fluid may seem easy to analyze, making accurate measurements of such fluids can be a daunting task. For the measurement to be valid, several factors need to be known and held constant, including:

temperature

In terms of importance, temperature is to viscosity and viscosity is to base oil. The sole responsibility of the temperature-controlled bath is to ensure that the entire viscosity measurement experiment is maintained at the exact temperature (typically 40 or 100 degrees Celsius) and controlled to within 0.02 degrees Celsius. Managing baths to this extent can be challenging, which is why more sophisticated viscometers include a temperature controlled bath system as part of the unit.

Glass Viscometer

Capillary viscometers depend not only on temperature accuracy, but also on the precise inner diameter inside the tube. Therefore, these glass tubes are made from fully annealed, low expansion borosilicate glass and often carry the viscometer constant associated with the tube as a correction factor. It is common practice to recalibrate the constants of the viscometer once a year and according to the temperature of use to ensure that the error is as small as possible. Calibration methods are specified in ASTM D446.

Viscometer size

Viscometer sizes vary for the many viscosities that can be tested. To avoid human error, it is recommended that the viscometer requires at least 200 seconds (for manual measurements using a stopwatch) for the test fluid to flow from one marked point to the next.

Rinse between measurements

Another important testing factor for viscometers is the quality of the in-tube rinse between measurements. Typically, the cleaning, rinsing and drying stages are carried out using various residue-free solvents. In laboratories that use high-volume viscometers to continuously run samples, the built-in cleaning system ensures cleaning efficiency. Still, a visual inspection is needed to determine if a second rinse cycle is needed, especially with used oil.

Other important factors that can affect viscosity measurements include the method and accuracy of the timing device, proper sample handling, and in-depth and continuous quality control.

Viscosity measurement has evolved over the years in various styles and methods. Thanks to ASTM and the International Organization for Standardization (ISO), viscometer test methods, procedures, calibration, cleaning and other factors have also been developed to ensure accuracy and consistency between different viscometers.

After all, viscosity is an important physical property of base oils, and the effort to measure viscosity with careful methods and rigorous standards can equate to more reliable machinery lubrication and, ultimately, longer-lasting machinery.