Rhopoint IQ integrates four functions of gloss, reflective image quality RIQ, haze, and image distinction DOI.

Why Measuring Gloss Isn't Enough?

Over the years, standard gloss meters have been specified and used as a quality inspection tool to quantify and verify the quality of surface appearance. It is based on a time-honored measurement principle that compares the amount of light transmitted to a surface at a measured angle with the amount of light reflected from the surface. This will produce a glossiness value unique to that surface. However, this gloss value is generally not misleading because it does not define other visually perceivable surface appearance effects.

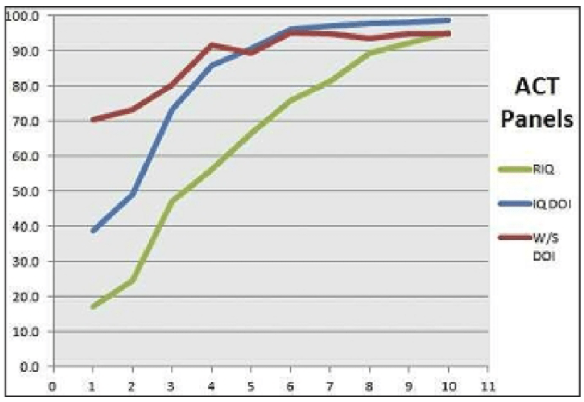

The ten panels above demonstrate this visual difference.

Each panel produces the same gloss when measured with a standard gloss meter, but appears different to the eye.

This visual versus measured difference is due to the large (orange peel) and microstructure (haze) resulting in texture on the surface.

Due to limitations in the measurement technique, the gloss meter cannot detect these structures as it can only determine the gloss value, hence why the surface appears visually unacceptable.

What is gloss and how is it measured?

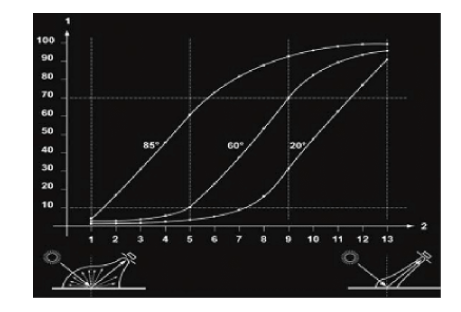

The reflectance values of low-gloss matte surfaces are too low to detect any difference by visual inspection - so the importance of gloss cannot be overemphasized.

However, as reflectance values increase towards high gloss, the effect of surface texture becomes more pronounced, so, as mentioned above, for these surfaces it is preferable to use a 20 degree angle for greater accuracy and resolution.

Gloss is the visual perception related to the perceived brightness of direct light reflected from a surface. Surfaces with high reflectivity are identified as glossy; less reflective surfaces are semi-gloss or matte.

Gloss meters quantify this effect by measuring the specular light reflection of a surface under equal but opposite lighting angles at a defined angle.

gloss unit

Gloss units (GU) are defined in international standards including ISO 2813 and ASTM D523. It is determined by the amount of light reflected by a glass standard of known refractive index.

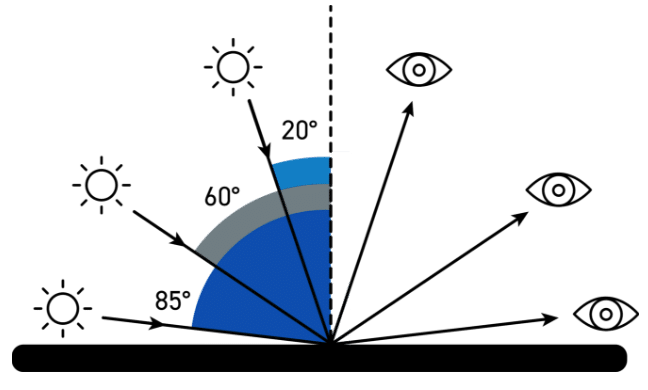

Common measurement angles for gloss are 20°, 60° and 85°.

A more suitable angle should be selected according to the glossiness of the sample surface.

Using the correct measurement geometry increases resolution and improves the correlation of results to human perception of quality.

how to determine a good angle

In order to determine the correct measurement angle, the surface should be evaluated using the 60° geometry -

Dull surfaces less than 10 GU below 60° shall be remeasured at an angle of 85°.

High gloss surfaces exceeding 70 GU@ at 60° shall be evaluated using a 20° angle.

The 60 degree angle is suitable for medium gloss measurements on samples between 10-70 GU.

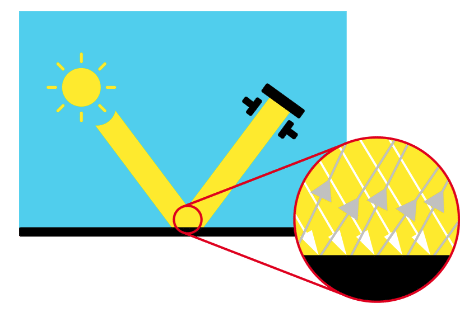

law of reflection

反射定律是入射光的方向,反射的出射光的方向与表面成相同角度。

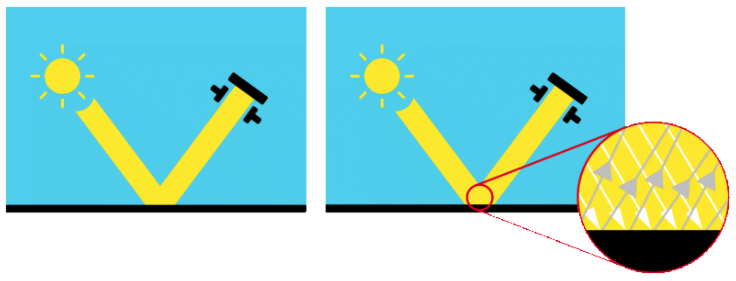

使用光泽度仪在20°下测量光泽度的标准方法要求围绕20°的镜面反射角±0.9°的接受角。

反射光的这种狭窄的角度测量范围不允许光泽度计中的传感器检测表面上的纹理,因为纹理内的结构导致反射光以更大的角度偏转。

使用Rhopoint IQ测量光泽度

该仪。Rhopoint IQ是光泽计不同,因为它使用一个线性二极管阵列(LDA),在20℃测量12.75°之间的反射光的分布- 27.25°。

常规光泽度计光学器件在60°和85°时使用,并且完全符合国际光泽度标准,例如ISO 2813和ASTM 523。

该仪器没有像常规光泽度计那样的物理接收器孔;通过使用线性阵列中与标准规定的角度相对应的元素进行测量,可以获得20°光泽度值。

此功能使仪器可以量化表面纹理的影响,According to其大小可以将其分类为桔皮或雾状。

什么是雾度?如何测量?

什么是雾度?

雾度是已被邻近主镜面角的非常小的表面结构反射的光。术语“雾度”定义了在高光泽度表面上肉眼观察到的乳白色光晕或起霜。

表面雾度

在大多数涂料应用中,包括汽车制造,粉末涂料和其他高光泽涂料,表面雾度可能会成问题。这可能归因于多种原因,包括配方中的材料不相容,分散性差以及在干燥/固化/保存过程中遇到的问题。

可以看到没有雾度的涂层具有深反射并且具有高反射对比度。那些雾度高的表面表现出轻微的“乳白色”外观,可以在高度光泽的表面上看到。

雾是由微观表面纹理引起的,该纹理使邻近反射光主要成分的光散射。

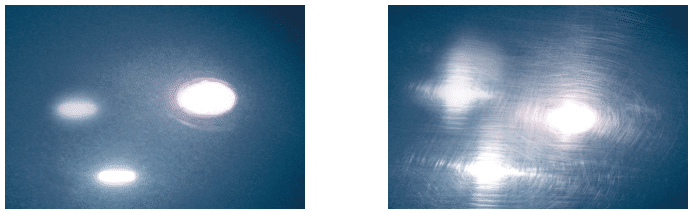

在雾度高的表面上观察强光源的反射时,图像会“泛光”,并且周围有明亮的光晕。

雾度是高度抛光金属的重要措施,通常与抛光痕迹和加工方向有关。

使用Rhopoint IQ测量雾度

使用Rhopoint IQ中的LDA技术,通过使用ASTM E430中描述的程序,通过分析在镜面反射角的任一侧+/- 2°偏转的光量,可以轻松实现雾度的测量。

还包括雾度补偿,以允许在不同颜色的表面上进行雾度测量,否则由明亮的颜色(例如白色,黄色)引起的光扩散将产生更高的雾度,即使它们相同。

该测量在一个过程中由仪器自动执行。

什么是橘皮和DOI,如何测量?

什么是DOI?

顾名思义,图像的清晰度是涂层表面反射图像的清晰度的函数。

用相似的涂层精加工的两个表面可能具有相同的光泽度,但是从视觉上看,一种涂层的质量很差。在仔细检查后,视觉上不合格的劣质涂层具有被称为“橙皮”的高度纹理化的凹陷外观。当在这样的涂层中观察反射的物体时,图像变得模糊和失真。

什么是橘皮?

在许多高光泽度涂料应用中,包括汽车,粉末涂料和任何需要光滑均质的行业中,橙皮,波纹,纹理,针孔和类似效果都会成问题。所有这些影响都可以使用Rhopoint IQ进行测量。

在汽车行业中,DOI已通过仪器和主观方法进行了测量。过去测量此值的仪器价格昂贵,有些仪器的可重复性很差。由于设备成本高昂,对DOI的测量在汽车外部并不常见,因此对高质量光泽的要求也不是那么重要。

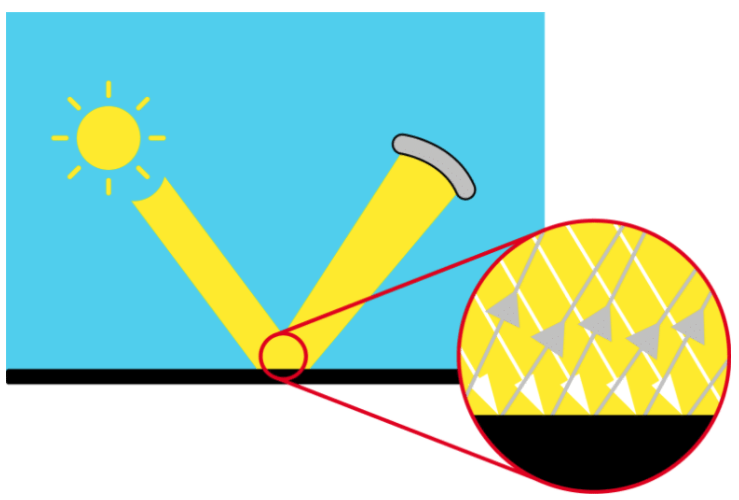

使用Rhopoint IQ测量橙皮和图像的清晰度(DOI)

该仪。Rhopoint IQ措施表面的DOI通过定量的方式反射的测量光束是扩展和周围的镜面角度扭曲。

低和高DOI值的示例测试面板。在高光泽质量变得越来越重要的涂料应用中,可以评估橘皮,质地,流出物和其他关键参数。

表面的DOI值是介于0到100之间的数字;呈现很好无畸变图像的表面返回100值,随着纹理的增加,图像变得失真,DOI值减小。

图像区别的缺点

图像的清晰度(DOI)是定义表面纹理的首批参数之一,它最初是一种视觉和仪器测量。

顾名思义,图像的清晰度是涂层表面反射图像的清晰度的函数。随着在表面上可见更多的橙皮,反射图像的清晰度降低。

通过量化光在镜面反射角附近的反射的方式,可以通过仪器来测量此效果,具有尖锐反射的完全平滑的表面的DOI为100,随存在的橙皮的数量而减少。

尽管DOI参数适用于其开发期间可获得的光洁度的细度,但当今涂料的质量已经提高到了DOI在许多行业中不那么重要的衡量标准。

What is Reflected Image Quality (RIQ)?

Reflected Image Quality is a new measurement developed by Rhopoint Instruments that provides increased sensitivity when evaluating specular/diffuse elements of highly reflective coatings and lower gloss materials.

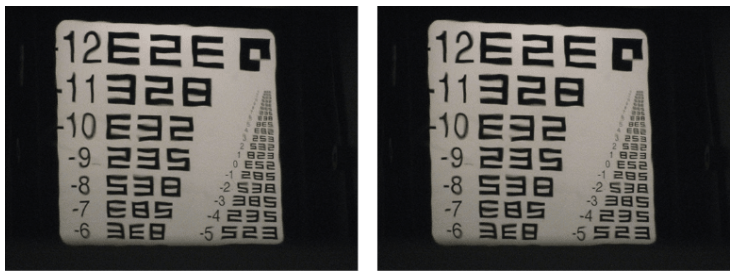

Two highly reflective surfaces that show little or no change in DOI due to little change in orange peel or texture, yet are quite different in appearance.

By reducing the sensing distance near the specular reflection angle and measuring the distortion of the reflected light and its surroundings, a higher resolution response and greater linearity can be achieved, which is more in line with the visual experience.

Two highly reflective panels with the same gloss value show little change in DOI but look different. However, greater discrimination can be achieved when using RIQ.

The RIQ value of a surface is also a number between 0 and 100; a surface that renders a nice undistorted image returns a value of 100, since as this value decreases, higher surface texture is present and the image is less sharp.