测量任何表面粗糙度的能力对机械工程师来说都是金尘,可以创建准确的仿真模型。

对于人眼而言,光滑的表面与机械工程师的外观可能大不相同。

能够确定在两个物体/表面之间生成的摩擦应力,使机械工程师可以准确地预测零部件的使用寿命。

制动系统依靠轮廓仪来精准测量表面粗糙度并最大化安全性

轮廓仪是一种高度专业的气象测量设备,用于确定表面粗糙度。作为一种测量仪器,轮廓仪非常精确,因为它有望识别和量化非常小的表面特征。According toISO 4287标准,将表面的粗糙度分为从“ N12”到“ N1”的等级(单击此处以获取图表和其他有用信息),并且粗糙度从微观斜率,峰和谷之间的最大高度差达到50微米至25纳米。

轮廓仪的实用价值

对于开发高精度系统并希望预测其性能和预期寿命的工程师而言,能够确定表面的粗糙度重要性无庸赘述。这里有一些真实的例子,说明如何使用轮廓仪来加深我们的理解并帮助我们优化生产和加工过程。

确定两个接触体/表面之间生成的接触刚度。

确定两个物体/表面彼此接触时产生的摩擦应力。

预测互连零件装配中的振动风险。

According to检测到的粗糙度图案,确定用于制造表面的加工类型。

确定润滑元件的表面是否足够粗糙以保留油分子。

预测制动系统组件的性能。

测量薄膜或涂层材料的厚度。

确定表面的反射级别。

确定FDM制造单元或CNC加工工具的精度和整体性能。

According to检测到的在某些操作条件下会恶化的裂纹或不规则度,预测组件的生命周期并确定其最大性能极限。

轮廓仪的类型

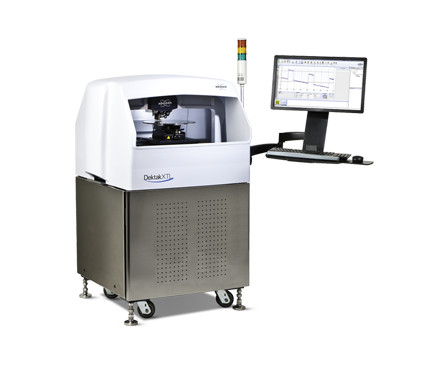

钻石测针轮廓仪

These were the original profilers, first introduced in the 1940s, and worked much like LP players. A probe consisting of a stylus tip is held in place by a feedback mechanism and moves along the surface being inspected, while an arm attached to the probe follows a vertical motion that helps generate contour waveforms. Since the signal is determined by the simulated movement of the diamond stylus, the size, radius, tracking force and probe speed of the stylus are all factors that determine its accuracy and resolution. In general, diamond stylus profilers are preferred for applications where roughness detection on the order of 10-20 nm is required and the surface is not clean enough to use contact methods and where surface reflectivity and coloration may trick other (optical) profiler types . The disadvantage of diamond stylus profilers is that they cannot be used on soft surfaces due to the formation of scratches and it takes some time to perform.

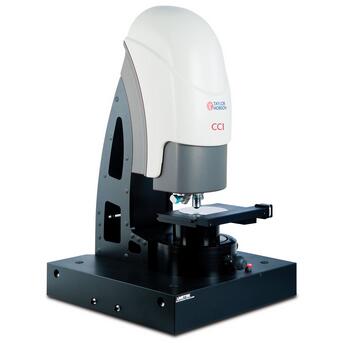

Digital Holographic Microscopy (Time-Resolved)

As the title suggests, this is an optical method that can determine the roughness of a surface using confocal chromatic aberration, laser triangulation, coherent scanning interferometer, structured light scanning, and other application-specific techniques. Although these profilers are not as accurate as diamond styli, they are very good for applications down to the micrometer. Their advantages include the fact that they produce profiling results very quickly, they do not touch the surface so the probe cannot damage or scratch it, and therefore they are the only way to measure the roughness of soft materials such as polymers , gel, etc.

Fiber Profiler

A fiber-optic-based profiler is an instrument whose detection probe and Detector data analyzer are located remotely from each other but connected by a fiber optic cable. The use of these cables provides zero signal attenuation, so engineers can measure the roughness of surfaces that cannot be reached for any reason. Example applications include measurements in radioactive chambers, cryogenic installations, toxic fume chambers, or components not intended for long-term maintenance (or long-term maintenance).