Hardness describes a material's resistance to permanent indentation or scratching. Hardness is not a material property, but a value assigned to a material based on empirical testing.

Six main hardness tests can be performed: Vickers, Rockwell, Brinell, Mohs, Shore and Knoop. Which material to use depends on the type of material being tested and the equipment available. Most hardness tests involve the use of a machine that presses into the material for a certain amount of time, applying a predetermined force or load.

This article will examine each type of hardness test independently, comparing test methods, applications, and types of results obtained.

Mohs hardness test

The Mohs hardness test was one of the earliest attempts to define and compare the hardness of mineral materials. The Mohs scale consists of values from 1 to 10 that relate to a test material's ability to withstand scratches from progressively hardening minerals. It is often used for geological purposes.

The Mohs scale of mineral hardness is as follows:

talc

Gypsum powder

Calcite

fluorite

apatite

Feldspar

quartz

topaz

corundum

diamond

The test method itself is very basic and involves scratching the surface of the test material with another material similar to that specified in the scale above. Actual minerals, especially diamonds, are rarely used because of the high cost of sourcing them.

For example, nails are commonly used to represent a hardness scale of 2.5, and steel files are used to represent 6.5. The test procedure consists of starting from the soft end of the scale until a permanent indentation is made by one of the minerals/materials in the sample.

The results of the Mohs hardness test are not very accurate because the force applied is not constant and the results are subjective.

Shore hardness test

Shore testing involves the use of a spring indenter to measure the hardness of a material. The Shore hardness test is commonly used to identify and compare the hardness of polymers such as plastic or rubber.

Two types of Shore scales - A and D - were used. They all use different diameters for the needle indenters and are suitable for different types of materials.

The indentation instrument used is called a "durrometer" and consists of a calibrated spring to which a defined and constant load is applied.

| material type | Indenter tip diameter (mm) | Applied load | |

| Shore A | Soft polymers and elastomers such as rubber | 0.79 | 822 grams (1.812 lbs) |

| Shore D | Rigid polymers such as thermoplastics | 0.1 | 4536 grams (10 lbs) |

Results vary between a minimum Shore hardness of 0 and a maximum Shore hardness of 100, which is associated with zero penetration.

Brinell hardness test

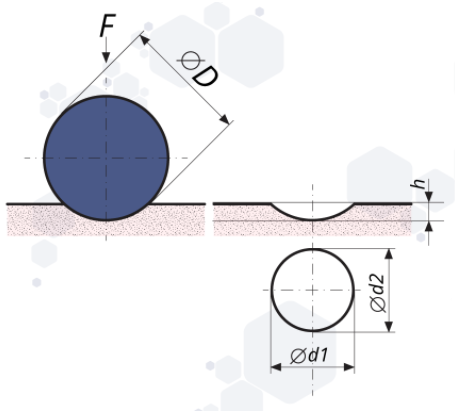

The Brinell hardness test was the first standardized test to be widely used, especially on metals. It is defined in ASTM E10. The test procedure consists of pressing a carbide ball indenter into the surface of the test material with a constant force for a set period of time.

Commonly used forces range from 500 kgf (typically used on non-ferrous metals) to 3000 kgf (typically used on steel).

The result of the testing process is a circular indentation which can be measured and used together with the applied load to calculate the hardness value. The disadvantage of the Brinell test is that it is slow and destructive compared to other methods, leaving large indentations in the test sample.

Rockwell hardness test

The Rockwell test is probably the most commonly used hardness test today, mainly because it is a fast and accurate form of testing. It is defined by standard ASTM E18.

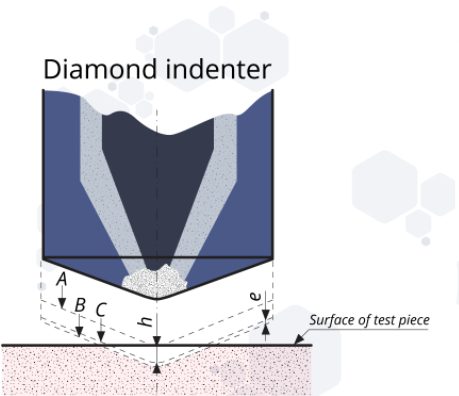

The Rockwell hardness test is divided into three stages. Diamond or spherical indenters apply preload for a short time. The preliminary load is then removed and the indentation is measured. A load is then added and applied, called the main load. The main load is then released and the initial load is reapplied for a short time. The indenter is removed and the final indentation is measured. The Rockwell hardness value for a material is calculated from the difference between the final and preliminary indentation depth measurements.

Depending on the type of test material, the applied force is between 15 kgf and 3000 kgf.

Vickers hardness test

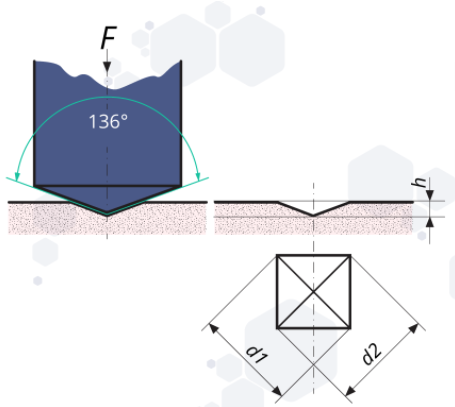

The Vickers hardness test is called a "microhardness" test, which means it is usually used on smaller or thinner sections of material. Microindentation testing of materials is defined by ASTM E384.

The testing process involves applying slight force to the surface of the material using a diamond indenter and measuring the depth optically. Due to the small indentations, the surface of the material needs to be smooth and highly polished.

Typical load values range from 10 g to 1 kgf, although "macro" loads are rarely used, with maximum loads up to 30 kgf.

Knoop hardness test

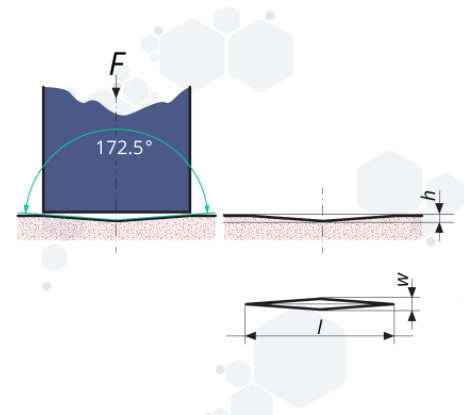

Similar to the Vickers test, the Knoop hardness test is suitable for small and thin parts with loads less than or equal to 1 kgf.

The procedure is the same as Brinell hardness testing, but uses a diamond indenter and a microscope measuring system.