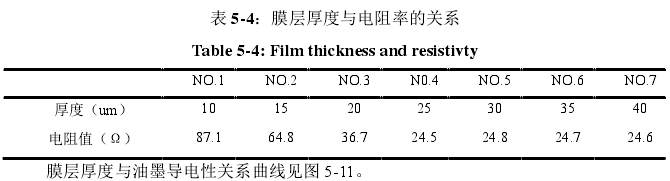

In screen printing, different pressures will lead to different film thicknesses, and the film thickness will directly affect the conductivity of the printed circuit . In manual screen printing, conductive lines with different film thicknesses can be printed by changing the pressure of the squeegee. Seven sets of sample printing experiments with different printing thicknesses were designed for the test. Table 5-4 shows the resistance values at both ends of the conductive lines with different film printing thicknesses .

Analyzing Figure 5-11 , in the initial stage, the resistance value of the conductive line decreases greatly with the increase of the printing thickness of the film layer, that is, the conductivity increases sharply. The reason is that when the printing thickness increases at the beginning, the content of the conductive filler (nano-silver powder) is greatly increased in proportion , that is, the contact area of the conductive filler is increased. When the thickness of the film layer increases to about 25um , the resistance of the entire circuit pattern hardly changes, and the ink film layer is too thick, which brings and is not conducive to drying.