When the high-speed disperser is used for pigment dispersion, the grinding slurry in motion should be laminar. The millbase should be fairly viscous (but still flowable), with a slightly dilatant flow being the desired fluid state. The preparation of this high-viscosity paint base can adopt high-viscosity paint or high pigment content, or a combination of the above two methods. Considering both economy and grinding efficiency, it is considered appropriate to adopt a medium viscosity paint with a lower solid content and a high pigment content. This is because:

More high-speed dispersing machine products enter: https://www.nbchao.com/list77/

a. High-pigment-content lacquer can make the amount of pigment processed by the grinding and dispersing equipment per unit time and unit volume larger, and a relatively large number of color paint products can be prepared with qualified varnish, so the grinding and dispersing efficiency is high. ;

b. Due to the tight packing of the pigment particles in the high-pigment content of the mill base, it is easy to cause the mill mill base to tend to expand and flow-produce the rheological state of the mill base suitable for the high-speed disperser;

c. The medium-viscosity paint penetrates into the pigment agglomerates and the gaps of the aggregates faster, which is beneficial to the wetting of the paint by the paint;

d. The use of lower content of medium-viscosity paint is based on the consideration of the stability of the grinding mill base. For from a purely wetting point of view, paints consisting almost entirely of solvents are desirable. In this way, the viscosity of the liquid is extremely low and the surface tension is small, so it can quickly penetrate into the pigment pores and spread out on the exposed pigment surface very quickly to achieve the purpose of wetting. However, this kind of liquid paint with a high proportion of volatile solvents makes the dispersion of pigments a short-term phenomenon. The relatively stable pigment dispersion system we require should be the base material (that is, 100% non-volatile solid resin) ) instead of the solvent preferentially wets the surface of the pigment. In order to obtain a durable grinding dispersion, it is necessary to add enough binder to make a continuous permanent coating around the pigment, which can further ensure the stability of the pigment particles. sex. When determining the viscosity of the paint, the wetting effect should be considered based on the premise of stability. Therefore, a medium-viscosity paint with a slightly lower solid content (not the lower the better) should be selected to form the abrasive slurry. This basic principle is also consistent in the design of other impact or mixing grinding equipment (such as sand mills and ball mills) for grinding mill slurry.

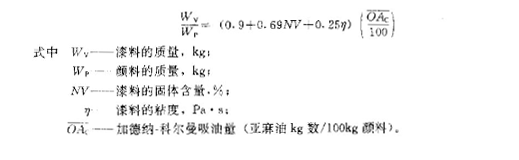

实验证明,漆料中树脂的固体含量至少应为15%,加之考虑在制漆阶段加入的调漆用漆料和研磨漆浆的含量不宜相差过大,以利于保持漆浆分散状态的稳定,建议采纳的漆料固体含鼓在20%~35%(质量)范圈内。在此漆料中添加足够的颜(填)料,制得的高粘稠度研磨漆浆,在剪切速率为400s-'时,粘度值约为3.CPa·s即为合适。According to生产中使用高速分散机的实际数据分析,Guggenheim导出了漆料固体含量(NV),漆料的粘度(η)和加氏-柯氏吸油量与最适宜的滚料-颜料质量比的关系即为古氏经验式。

方程式表明 之比,以

之比,以 ![]() 项为基础增加了两个修正项一项是

项为基础增加了两个修正项一项是![]() 另一项是

另一项是 。这两项都是随着漆料固体含量和粘度的降低而导致研磨漆浆中漆料量与颜料量之比(Wv/Wp)降低,即研磨漆浆中颜料分的提高的。而且在树脂分子量固定的前提下,式中的漆料粘度实际上是随着漆料的固体含址的变化而变化的,因此确定很好的配比的关键是确定透宜的漆料固体含量,如上所述,我们可以在固体含量为20%~35%漆料中,任意选定几个数据(如20%、25%、30%和35%)测定出其对应的粘度。代入式计算其研磨漆浆组成,由实验证哪种组成效果更佳,便可方便地求得适用于高速分散机的研磨漆料的合理组成了。

。这两项都是随着漆料固体含量和粘度的降低而导致研磨漆浆中漆料量与颜料量之比(Wv/Wp)降低,即研磨漆浆中颜料分的提高的。而且在树脂分子量固定的前提下,式中的漆料粘度实际上是随着漆料的固体含址的变化而变化的,因此确定很好的配比的关键是确定透宜的漆料固体含量,如上所述,我们可以在固体含量为20%~35%漆料中,任意选定几个数据(如20%、25%、30%和35%)测定出其对应的粘度。代入式计算其研磨漆浆组成,由实验证哪种组成效果更佳,便可方便地求得适用于高速分散机的研磨漆料的合理组成了。

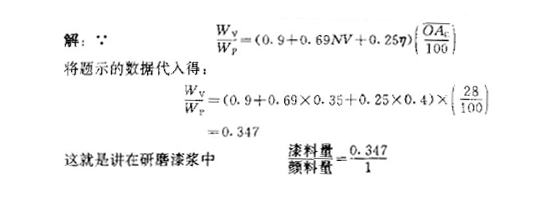

例题:以粘度为0.40Pa·s,固体含量为35%(质量)的醇酸树脂漆料和吸油量为28的颜料,用高速分散机制备研磨滚浆,试计算适宜的研磨漆浆组成。

研磨漆浆总量=1.347

基于此求得研磨漆浆组成为:

基料量=0.347×0.35=0.121,占总量的0.121/1.347=9.0%

溶剂量=0.347×0.65=0.226,占总量的0.226/1.347=16.8%

颜料量=1,占总量的1/1.347=74.2%

研磨漆浆总量为100.0%

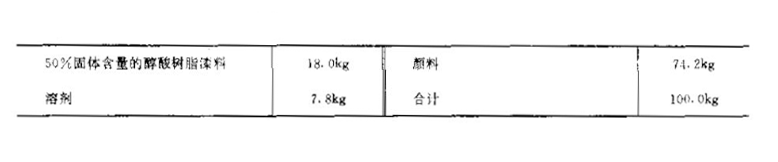

Under normal circumstances, paint factories will not use 100% solid content of base paint for color paint manufacturing, assuming that 50% solid content of alkyd resin paint is used to prepare ground paint in this question, because of the above Calculation is known, if the preparation of 100kg of grinding mill base material needs to add 9kg, then the paint with 50% solid content needs to add 18kg (including base material 9kg, solvent 9kg), and then add more solvent, then Deduct from the 16.8kg of solvent that should be added to the millbase. Therefore, the composition of preparing 100kg of grinding mill slurry is: