1. Structure and characteristics

As shown in the picture, the horizontal ball mill has a grinding cylinder mounted horizontally on bearings, which can be made of steel or lined with steel. The cylinder is filled with porcelain beads or pebbles as grinding media. The barrel is provided with a feeding port and a feeding port. When the motor is running, it is decelerated by the reducer, and the grinding cylinder is driven to rotate around its axis. At this time, the grinding medium in the grinding cylinder is lifted up, and then slides down while rolling in a pouring state. The balls either collide with each other or rub against each other. However, the impact and shear action are provided to de-aggregate the large pigment particles and have a certain crushing effect. At the same time, the paint paste between the balls is in a highly turbulent state, which disperses the pigments.

The advantages of the horizontal ball mill are: no pre-mixing tank is needed, pigments and paints can be put into the ball mill and mixed and dispersed at the same time, because it is a closed operation, the solvent in the paint paste will not volatilize, so it is suitable for paint paste with high volatile content or poisonous substances processing. The horizontal ball mill is suitable for the dispersion of all paint pigments, and it is more unique for the pigments that are easy to thicken and thicken (such as carbon black, iron blue, etc.) and are difficult to disperse. In addition to feeding and discharging, normal operation does not need human control. The disadvantage is that the operation cycle is long, it is not easy to clean each batch of paint paste, it is difficult to change the color and variety, and it is noisy, and it cannot process thicker paint paste.

2. Factors Affecting Dispersion Efficiency

a. Grinding drum speed

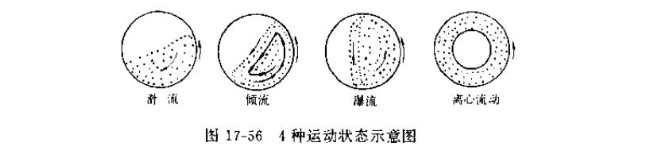

As shown in the figure, with the different rotation speeds of the grinding cylinder, the ball presents four different motion states in the grinding plate :

Sliding state: when the rotating speed is slow, the ball group forms a static unit, which moves relative to the rotating cylinder wall, and it is difficult form a dispersing ability;

Inverting state: When the speed is appropriate, after the balls are continuously lifted, the balls themselves are also rolling continuously . The spheres rub and collide with each other, thus forming the ability to disperse the paint slurry in the gap between the balls;

Waterfall state: When the rotational speed reaches a certain level, some balls fly out of the paint paste and fall through the other half of the space. At this time dispersion ability is very poor, and the balls and the wall are damaged;

离心流动状态:转速过高时,球与漆浆受离心力作用而贴附于筒壁上,球体之间、球体与简壁间形不成相对运动,敌而没有分散能力。

因此,倾流状态是分散颜料所希望的称心状态。它既有球自转又有球群移动,因而分散效率较高。决定运动状态的主要原因是磨筒的转速。球磨的大小和很好的转速的关系见表。

| 球磨直径,mm | 300 | 600 | 900 | 1200 | 1500 | 1800 | 2100 | 2400 | 2700 | 3000 |

| 很好的转速,r/min | 50.0 | 33.7 | 26.2 | 21.5 | 18.2 | 15.6 | 13.6 | 11.9 | 10.5 | 9.2 |

球磨大小和很好的转速的关系

b,研磨介质

研磨介质的直径越大,撞击力也越大,但球间摩擦面积小﹔反之,直径越小,撞击力越小,但摩擦面积大,球与球之间碰撞的频率增加,因此球体直径应选择适当。

通常,粘稠状的漆浆对于球体自由运动的阻力大,故应选用直径大一点的球以增加球在物料中进行滚动、撞击摩擦的作用力。对于粘稠度低的物料可选用直径小一点的球,以增加球间的摩擦面积和碰撞频率来提高分散效率。实践证明,使用瓷球作研磨介质的直径在20~30mm左右效果更好。以鹅卵石为研磨介质时则以长短平均直径在25~40mm之间为佳。

c,研磨介质与漆浆装量

If the amount of grinding media is too small, the production efficiency will be low, but if the amount is too much, not only the loose powdery pigments will be inconvenient to feed, but also the space above the grinding plate will be small, the rolling stroke of the ball will be short, and the production efficiency will also decrease. Practice has proved that the loading capacity of ball milling media for coatings is preferably 50% of the volume of the grinding cylinder. It is advisable to add 5% to 10% of the filling volume on the basis of filling the media gap. In this way, every time the ball mill rotates once, all the slurry can be ground once. Since the amount of slurry is increased by 5% to 10%, there is a layer of slurry with a certain thickness between the grinding medium and the ball mill cylinder, which can not only improve Grinding and dispersing efficiency, at the same time, it can reduce the wear of the barrel wall of the ball mill.

d. Composition of paint paste

A well-considered product formula and a reasonable composition of grinding slurry are important factors to improve the efficiency of grinding and dispersing. The grinding slurry composition of the sand mill is also suitable for the horizontal ball mill .