All test items need to be inspected under the specified temperature, humidity and thickness. ISO 3270 and GB9278/T- 88 stipulate standard environmental conditions (anyone with such conditions should adopt) temperature 23°C ± 2°C, relative humidity 50 ± 5% or standard temperature 23°C ± 2C, relative humidity is ambient humidity .

1. Film-forming properties

① Curing conditions

Under the baking conditions of different temperatures and times, the prepared coatings were tested for gloss, impact resistance, bending and cupping, and the temperature and time with good comprehensive performance were selected as the curing conditions.

② Overbaked

According to the curing conditions specified by the powder coating, after doubling the baking time, observe whether the coating film will cause obvious changes in gloss, color, elasticity and impact properties. The test method can be carried out according to ASTM D2454 method.

③Film thickness

See GB/T1764-89 for paint inspection method for details.

2. Optical properties

①Measurement of gloss

See GB/T1743-89 and GB/T9754-88 for details. At present, the fixed angle is 45°, while the international standard (ISO) uses different incident angles for various varieties when testing gloss. Gloss coating, 85° test low gloss coating. Therefore, according to the situation of coating varieties in our country, it is planned to use a multi-angle gloss meter in the future. The incidence angle of 60° is used when the gloss is between 30% and 70%, the incidence angle of 20° is used above 70%, and the incidence angle of 85° is used below

②Leveling

Observe with the naked eye and use a grading method to evaluate. A rating of 0 is very good and a rating of 5 is very poor.

③ Hiding power

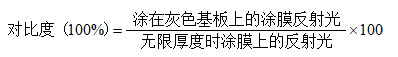

Contrast was measured with a phosphated gray substrate as a measure of hiding power. Can be represented by the following formula :

④ Coverage of edges and corners

Evaluation was made by visual inspection.

⑤ Determination of color and appearance

It is evaluated by observing the color and appearance of the coating film and comparing it with the standard color plate and standard sample . See GB/T1279--85 for details.