The laboratory small-scale film coating machine can be equipped with wire rods, Wet Film Applicators, and scrapers for automatic coating proofing, and the machine can automatically scrape the film to liberate the efficiency of manual coating. Reduce the artificial factors (such as uneven pressure, uneven speed, etc.) due to manual film coating, and improve the repeatability and accuracy of the film coating by means of constant pressure and constant speed.

However, due to the different properties of different samples, there will be different requirements in the experimental coating process, such as maintaining a constant temperature, needing heating, and easy curling of the coated substrate, so different experimental coating opportunities are different, and can be used for different Special functional design is required.

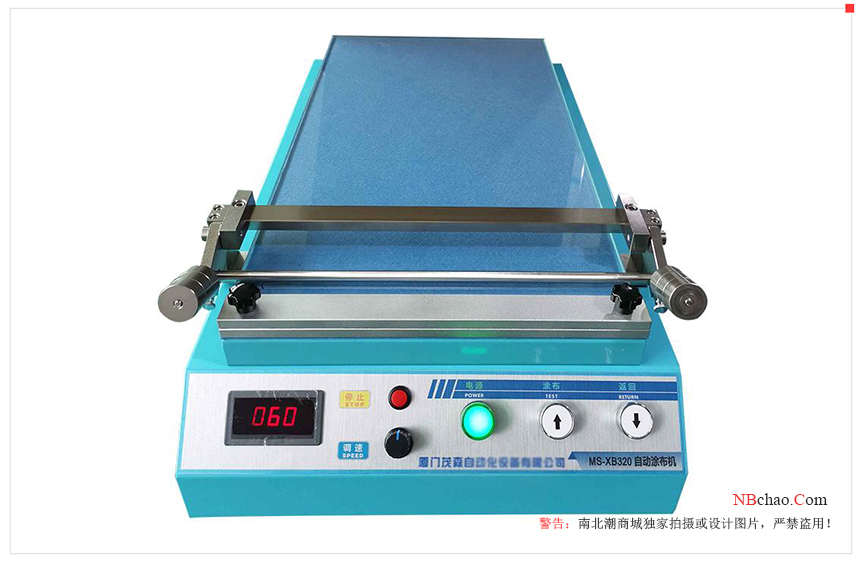

Before sharing different types of film coating machines, let's take a look at the structure and appearance of the experimental automatic film coating machine to see how to realize automatic film coating? NBCHAO took a video of Maosen's ordinary automatic film coating machine.

Under normal circumstances, the ordinary type of automatic film coating machine is a wiring rod or a scraper, the bottom plate is made of glass or aluminum plate, and the speed can be adjusted to realize automatic film coating. The pressure of the film coating process is controlled by adding weights on both ends of the clamping wire rod, and the film coating speed can be adjusted freely. In the video, this coating machine can automatically push the wire rod forward, and automatically reset to the original starting position after scraping.

In addition to the ordinary type, the laboratory automatic film coating machine also has several different types, such as heating type, heating vacuum adsorption type, and vacuum adsorption type. So which of these types is suitable for your laboratory testing needs?

Ordinary paragraph

Ordinary film coating machine is to meet the general experimental requirements, realize the basic automatic film coating operation, and simply replace the manual wire bar coating or scraper coating by the film coating machine. In general, the bottom plate is glass and has the function of speed regulation.

Heated Film Applicator

The heating type coating machine is based on the basic small coating machine with a heating function. Because some experimental coating samples need to be kept at a certain temperature to maintain the original normal fluidity, otherwise there will be solidification, which will affect the normal coating. film effect. Or retain its better properties by heating.

The more common heating temperature range is around 0~150°C. If the temperature is high, it can reach almost 300°C. For example, the integrated coating testing machine of Jinput can be customized up to 300°C. If it is equipped with a vacuum adsorption plate, too high temperature may cause slight deformation of the heating bottom plate (usually aluminum plate). This is a normal phenomenon, but it will not affect subsequent use.

Vacuum Adsorption Film Coating Machine

Vacuum adsorption film coating machine is to modify the base plate on the basis of ordinary coating machine to become a vacuum adsorption plate, aiming at soft and easy-curling substrates, to ensure the flatness of the substrate during the coating process and improve the coating effect, especially For thin film substrates, the effect is better. However, if it is a fabric-like substrate, it is not recommended to use vacuum adsorption, because the fabric is generally breathable and the effect is not good. It is recommended to fix it directly with both ends of the clip.

Heating Vacuum Adsorption Film Coating Machine

There is no doubt that the heating vacuum coating machine is a comprehensive version of the heating vacuum coating machine and the vacuum coating machine. With heating function and vacuum adsorption function at the same time, the price of the whole film coating machine equipment will be relatively high, costing tens of thousands of yuan.

The above are four different types of film coating machines, do you know which one meets your needs? Of course, in the selection of the coating machine, parameters such as the width of the coating film, the length of the coating, and the range of speed regulation will also be considered. If you need to choose an experimental coating machine, it is recommended to consult the technical customer service of Beichao, and we can provide you with professional selection service support!