A common method used by paint designers to evaluate adhesion is the ease with which a pencil sharpener can be used to scrape the coating away from the substrate. This requires experienced people to operate and is not suitable as a test method. Because experience is not easily transferred from one person to another , and the method lacks numerical expression. None of the test methods used to evaluate adhesion is very satisfactory. Scratch hardness, impact strength, flexibility and other test methods can indirectly show the adhesion of the paint film.

① Direct pulling method

At a specified speed, apply a vertical uniform tensile force on the bonding surface of the sample to measure the force required per unit area between coatings when the coating and the substrate are pulled apart. A general Tensile Testing Machine can be used for the test. During operation, a stick is vertically fixed on the upper surface of the coating sample with an adhesive, and a stick is also vertically fixed , and the two vertical sticks are back to back in a straight line. The assembly was placed in the grips of an Instron Tester and the force at which the coating was pulled away from the substrate was recorded. The sticks need to be in line with each other and perpendicular to the coating. If the stick is at a slight angle to the substrate, the stress is concentrated on only a portion of the substrate-coating interface, and less force is required to break the bond. Sometimes the weakest part is the substrate and this method cannot be used to measure bond strength.

The force of the adhesive to bond the stick to the coating needs to be greater than the adhesion of the coating to the substrate, and the adhesive must not penetrate the coating and into the coating-substrate interface. Available with 502 adhesive or epoxy two-component adhesive, cyanoacrylate adhesive.

During the measurement, the jig of the tensile machine was stretched at a speed of 10mm/min until it was destroyed, and its adhesion and failure mode were assessed.

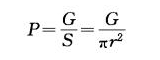

Due to considerable experimental error in this step, multiple tests are required. An experienced operator can obtain an accuracy of ±15%. The adhesion of the coating was calculated as follows:

In the formula, Р is the adhesion of the coating, Pa, G is the load value when the specimen is pulled apart and damaged, N; S is the cross-sectional area of the test column of the tested coating, cm 2 ; r is the tested coating The radius of the test column, cm.

GB 5216-85 "Determination of Coating Adhesion, Pulling Method" stipulates that there are four types of failure: adhesion failure, cohesion failure , adhesive failure, and cementation failure, which are represented by A, B, C, and D respectively. The test results are expressed in terms of adhesion and failure .

When the cohesion of the coating fails (ie the strength of the paint film itself is small), the strength of the adhesion is greater than . The sample has adhesion failure on the base plate-coating interface, and there are several possibilities: there is no coating on the base plate after the test, but a single layer (or thin layer) of material remains, and the adhesion failure occurs on the surface Between the adsorbed substance and the rest of the coating , surface analysis is required to determine the specific location of the adhesion failure and to identify the adsorbed substance. Usually adhesion failure and film cohesion failure occur simultaneously. When microvoids appeared in some places of the coating film and extended to the interface, the measured tension value of the sample was different from that of the adhesion failure sample.

The paint film direct pull test method can be used for direct testing in the field, and this equipment is widely used in the quality control of high performance maintenance coatings and marine coatings. The test method is destructive and the tested area needs to be repaired.

Adhesion is affected by the angle at which the stress is applied. An instrument named STA-TRAMⅡ has been designed and developed to apply normal load and side tension to the tested sample to test the damage caused by friction. This test is used to study the detachment of automotive plastic bumpers when they are rubbed against each other or scratched by solid objects.

②Cross-cut test method

Earlier, the safety blade was used to cut 6 parallel cuts on the paint film (about 10-20mm long, and the distance between the cuts is 1mm), which should cut through the entire depth of the paint film, and then cut the same cut 6 times , perpendicular to the former, forming many small squares, and then lightly touch with your fingers, the paint film should not fall off from the squares, but still firmly combined with the bottom plate is qualified . This method is relatively simple, does not require special equipment, and is suitable for application on the construction site, but the insurance blade is soft, and it is not suitable for thicker paint films or higher hardness. Hand cutting knives and mechanical cutting instruments . This is the result classification method according to the national standard GB 9286-88 "Cross-cut test of paint and varnish film". At present, the adhesion of the coating is generally good, and the cross-cut method alone cannot distinguish the good from the bad. At this time, it is necessary to use the adhesive tape method to obtain satisfactory results. The tape is generally 25mm wide translucent tape, and the backing material is polyester film or acetate fiber. Stick the tape on the entire grid, and then tear it off at the smallest angle. The result can be obtained , 0 is better and 5 is the worst.

The grading method stipulated in the B method in ASTM D3359-78 of the United States is opposite to the national standard of our country. The scratch adhesion test uses a device with 6 or 11 sharp blades to draw a line mark on the sample, and then draw again perpendicular to the first line. Use a piece of pressure-sensitive tape to stick tightly over the grid lines and lift. By comparing with a set of photographs, the quality of adhesion can be rated as 5-0, ranging from a small amount of fracture at the scratch to most of the peeling off in the area.

The rate of cross-cutting affects the test results. If the stroke is faster, the coating will be more brittle under the higher rate of stress, and it is possible for the crack to propagate outward from the cut. The pressure sensitive tape, the pressure applied to the film, the angle and speed at which the tape is removed from the surface, the bending of the substrate during the test, and the coated surface being taped all affect the test results. This test method is useful for distinguishing between poorly adhered and reasonably well adhered samples, but not very useful for distinguishing between higher adhesion classes .

③ circle method

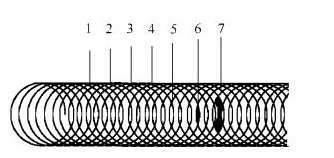

The national standard GB 1720-79 (88) stipulates the use of an adhesion Tester. The tip of the needle draws a certain length of overlapping circular rolling lines on the paint film , so that the paint film is divided into 7 parts with different areas, as shown in the figure. Where the paint film in the first part is intact, the adhesion is better, which is grade 1; if the second part is intact, it is grade 2; and so on , the adhesion of grade 7 is the worst.

Grading of adhesion by the circle method

The improvement of the current circle adhesion Tester is to use a wear-resistant needle with high hardness and long-term use instead of the stylus, so as to reduce the trouble of changing the needle for each test. There are also several batteries and a buzzer installed under the base of the Tester . When the needle tip penetrates the paint film and actually reaches the bottom plate, the buzzer will sound, and then the test can be carried out. This avoids experimental errors caused by uneven paint film thickness or sometimes when the needle tip does not actually touch the base plate.