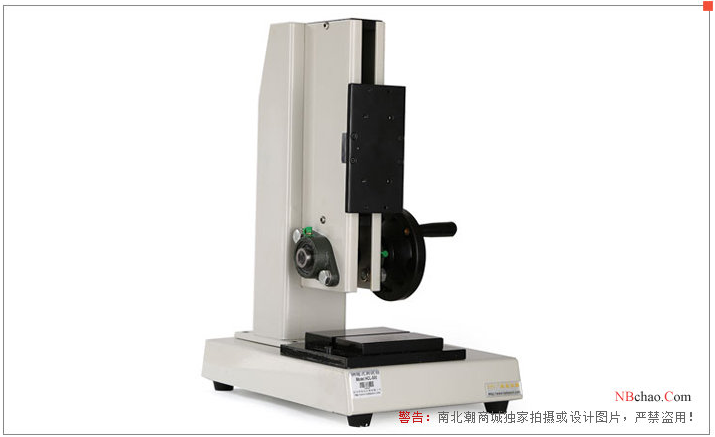

(1) Test device

The pressure wheel is a steel wheel covered with rubber, with a diameter (not including the rubber layer) of about 84mm and a width of about 45mm; the hardness of the rubber covered (Shore A type) is 80°±50°, and the thickness is about 6mm; Mass is 2000g ± 50go

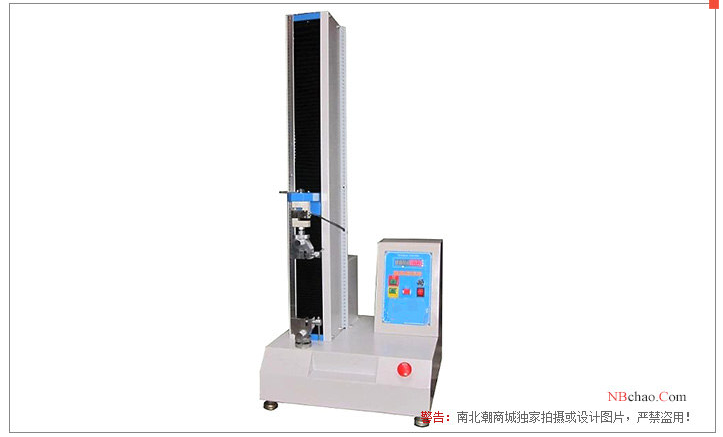

( 2) Testing machine

The Tensile Testing Machine should make the failure load of the sample between 15% and 85% of the full standard load. The force value indication error should not be greater than 1%. The testing machine peels off continuously at a descending speed of 300mm/min±10mm/min.

The Tensile Testing Machine shall be equipped with a plotting device capable of automatically recording the peel load.

( 3) Sample

①Adhesive tape There are two types of adhesive tape widths: 20mm±1mm and 25mm±1mm, and the length is about 200mm.

② Test board, the length of the test board is 125mm±1mm, the width is 50mm±1mm, and the thickness is 1.5~2.0mm.

The test plate material is OCr18Ni9 or 1Crl8Ni9Ti specified in GB/T 3280. Use water-resistant sandpaper with a particle size of P280 specified in JB/T7499-1994 on the surface of the test board, firstly sand it lightly along the horizontal direction, and grind light marks on the entire board surface, and then sand it evenly along the longitudinal direction to remove these marks. After the test board is used frequently and has not been used for a long time, it should be polished before use. When there is permanent pollution or scar on the surface of the test plate, it should be replaced in time.

If the test board is made of PVC, ABS or PE, its material and surface conditions can be stated in the test report.

(4) State regulation and test environment

State adjustment: Before preparing the sample, the sample roll (sheet) and the test plate should be placed at a temperature of 23°C ± 2°C and a relative humidity of 65% ± 5% for more than 2 hours.

The temperature of the laboratory is 23°C±2°C, and the relative humidity is 65%±5%.

( 5 ) Test steps

① Wipe the test panel with a cleaning agent, then dry it with a clean degreasing gauze, and repeat this process for more than three times until the working surface of the panel is clean through visual inspection. After cleaning, do not touch the working surface of the plate with hands and other objects.

②Measure the width of the tape with a tool with an accuracy of not less than 0.05mm.

③Before preparing the sample, first tear off the outer 3~5 layers of adhesive tape, and then take the adhesive tape of more than 200mm (the surface of the adhesive tape should not touch hands or other substances). And bond the adhesive tape to the cleaned test panel. Place a piece of polyester film or other material with a length of about 200mm and a width of 40mm under the other end of the test plate, and then roll it back and forth on the sample for three times at a speed of about 300mm/min under its own weight (the sample and the test plate stick together). Air bubbles are not allowed at the junction).

④After the sample is prepared, it should be parked in the test environment for 20~40min before the test.

⑤Fold the free end of the sample in half by 180°, and peel off the adhesive surface from the test plate by 25mm. Place the free end of the sample and the test plate on the upper and lower grippers respectively. The peeling surface should be consistent with the force line of the test machine. The testing machine peels off continuously at a descending speed of 300mm/min±10mm/min, and an automatic Recorder draws the peeling curve.

⑥When the double-sided pressure-sensitive adhesive tape is bonded to the stainless steel plate or other materials, first tear off the outer 3~5 layers of the double-sided adhesive tape, then take the adhesive tape over 200mm and paste it on the polyester film, and then Peel off the release paper on the other side, and conduct the test according to the regulations.

⑦ When measuring the peel strength of single-sided pressure-sensitive adhesive tape or double-sided pressure-sensitive adhesive tape and sheet, film and other materials, first paste the sheet, film, etc. on the steel plate, and then conduct the test according to the regulations.

(6) Test results

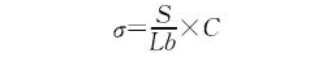

Pressure-sensitive adhesive tape 180° peel strength akN/m) is calculated according to the following formula:

In the formula, S - the area within the value range in the record curve, mm2;

L——the length within the value range in the record curve, mm;

b - the actual width of the adhesive tape, mm;

C——The load per unit height of recording paper, kN/m.

Within the peeled value range, read a number every 20mm, read 4 numbers in total, and calculate the average value. The number of samples in each group is not less than 3, and the test results are shown as the arithmetic mean value of the peel strength.