Usually new reverse osmosis membrane elements are soaked in 1% NaHSO3 and 18% glycerol aqueous solution, and stored in a sealed plastic bag. If the plastic bag is not damaged, it will not affect its life and performance if it is stored for about 1 year. When opening the plastic bag, it should be used as soon as possible to prevent NaHSO3 from oxidizing in the air and adversely affecting the components. Therefore, the film should be opened as much as possible before use. After testing the device, we used two methods to protect the film. After the equipment has been running for two days (15-24 hours), then use 2% formaldehyde solution for maintenance; or after running for 2-6 hours, please use 1% NaHSO3 aqueous solution for maintenance (the air in the equipment pipeline should be exhausted to ensure that the equipment does not leak , close all inlet and outlet valves). Both methods can achieve satisfactory results. The first method is more expensive and is used when the idle time is long, and the second method is used when the idle time is short.

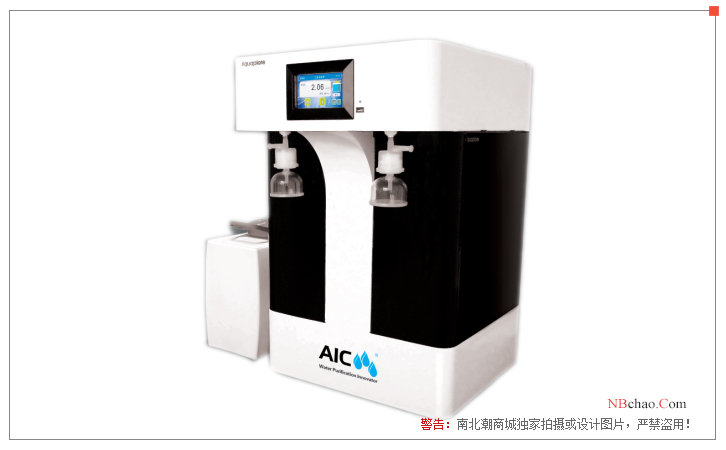

Pure water equipment, in simple terms, is the equipment that produces pure water equipment. And pure water equipment is widely used by us: drinking, chemical industry, medical treatment, breeding, planting, food, beverage, etc. The following briefly introduces the components of pure water equipment and the process of producing pure water equipment.

primary processing system

It is very important to rely on the production of pure water equipment. Therefore, if you want to produce pure water equipment, you must choose a place with better raw water quality. Such as mountain springs, deep wells, etc. A very important index involved here is "conductivity". Generally speaking, the conductivity is lower. The purer the water. The current water treatment process is the reverse osmosis system. The treated water can generally achieve a desalination rate of 90%-99%. Let me introduce the components of this system.

1. Raw water pump

The raw water pump is used to provide raw water pressure for the raw water pretreatment system. If the raw water is under pressure, this device can be completely omitted. Generally require raw water pressure>=0.3MPa

2. Raw Water Tank

The role of the raw Water Tank is simpler and is used to store raw water. This is for the fear of making a transfer in case the raw water is not available (usually adding a float switch makes the whole system more automated).

3. Quartz sand filter

Quartz sand filter material is used to remove larger particles of suspended solids, sediment, impurities, etc. in the raw water to reduce the turbidity of the water. Moreover, it can also remove a large amount of organic substances, bacteria, viruses, etc. in the water with the reduction of turbidity, and create good conditions for post-filtration disinfection.

4. Activated carbon filter

Use the adsorption capacity of activated carbon to effectively adsorb organic matter, free residual chlorine, colloids, particles, microorganisms, certain metal ions and decolorization in raw water.

5. Softening system

Use the exchange performance of ion resin to remove calcium and magnesium ions in raw water to prevent the subsequent equipment from forming scale, but the operation is labor-intensive and material-intensive. Now change to dosing system to add antiscalant directly into it.

reverse osmosis system

The reverse osmosis system is the core component of the entire pure water equipment system, and only through reverse osmosis can the standard of pure water equipment be achieved. The reverse osmosis system mainly adopts the reverse osmosis membrane filtration process. Water molecules can then pass through the reverse osmosis membrane. Other ions such as calcium, magnesium, and sodium are discharged together with the wastewater. The components of this system are introduced below:

1. Precision filter

This filter mainly filters large particle molecules in water.

2. Special high pressure pump

Generally, the high-pressure pump we use here is the southern special pump. Provide strong power for reverse osmosis equipment.

3. Reverse osmosis membrane

The reverse osmosis membrane uses membrane filtration technology. Let water molecules pass through other ions that cannot pass through to achieve the purpose of purifying water.

auxiliary system

Other auxiliary systems such as ozone sterilization system, light inspection, filling system. Ultraviolet rays can also be used to sterilize, and there will be no residue of ultraviolet rays. Now there are many people in foreign countries who like to use ultraviolet rays.

First of all, you must determine what kind of water purifier you are. The filter elements of the pipeline filter mainly include PP cotton, block carbon, activated carbon, ceramics, ultrafiltration, exchange resin, and RO reverse osmosis. The ceramic core can be used with a toothbrush and clean water. Brush, the exchange resin can be regenerated with saturated saline, and the ultrafiltration can be washed by backwashing.

The whole process :

Other filter elements are basically disposable. The life of PP cotton is 3 to 5 months, the life of block carbon and activated carbon is about half a year, and the life of RO reverse osmosis is about 2 years. The service life of the filter material of the central water purifier (used to purify water in the whole house) is generally 5 to 15 years, because the general central water purifier has a backwash function, which can prolong the life of the filter material, these are just basic Value, the specific life is determined according to the water quality and water consumption of the home.

A product that only replaces the filter element does not guarantee that the inner wall of the housing and the outlet pipe will not be polluted again. Different water purification products have different replacement cycles for filter elements. The lower-cost PP cotton needs to be replaced once a month, while the activated carbon needs to be replaced every three months.

In addition to replacing the filter element, the water outlet pipeline and other components must be cleaned and disinfected on time, otherwise the pollution caused by the equipment is much greater than that of untreated water. Therefore, it is particularly important to purchase quality water purifier products.

Clean the water purifier: imported food acid

Pure water equipment features:

1. Remove the algae on the inner wall of the water purifier;

2. Remove dirt and harmful bacteria attached to the hydrophilic membrane.

Advantages: food-grade raw materials, non-toxic, no harm to human body.