(1) Mobility

The fluidity of the powder is an important parameter as it is the main factor in the delivery and application of powder coatings. Fluidity can be measured by different methods, all of which require accurate control of temperature and relative humidity.

The more practical Selier flow measurement method is a test method published by the Netherlands National Science Research Center, and its test instruments have been manufactured by the French Sames company.

The test method is: weigh a certain mass of powder (about 250g) and put it in a cylindrical polyvinyl chloride container with a diameter of 100mm. The container has a porous bottom sintered with bronze, and the air is fed into it at a rate of 200L/h. inside the container. After the powder is fluidized for 1-10 minutes, let the powder flow out for 30 seconds through a hole with a diameter of 4 mm on the container wall, and measure the mass of the powder that flows out.

Mobility coefficient R can be calculated according to the following formula.

R=m·h 1 /h 0

In the formula, m——mass of powder flowing out;

h 1 ——the height of the powder layer during fluidization;

h 0 ——the original height of the powder in the container.

When determining the fluidity coefficient, it can be said that a well-flowing powder should have good data reproducibility. To comment on the effect of powder fluidity, reference can be made to the following data.

| Mobility coefficient | comment |

| >180 | very good |

| 140~180 | good |

| 120~140 | qualified |

| 80~120 | medium |

| <80 | Difference |

(2) Distribution of powder particle size

The commonly used test method is the dry sieve method. The method is to pass a certain amount of powder through a set of sieves with different sieve holes under the action of specified time and force, and then weigh the mass of powder remaining in each sieve, so that the mass percentage can be used to express the powder in the The composition of a sieve.

The mass percentage composition can be expressed by the following formula:

L (%)=m 1 /m 100

In the formula, L——the particle size distribution of each sieve, %;

m——total mass of powder, g;

m1——the mass of powder remaining on each sieve, g.

(3) Gel time

Gel time (or gel time) is an effective method to determine the degree of activity of powder coatings.

A simple test method is to put 2g of powder coating on a Hot Plate adjusted to a specific temperature (eg: 100 ℃ ± 2 ℃ ), and then use a wooden tongue plate along a circular ring about 25mn in size The route is constantly moving. When the tongue plate is lifted to a height of about 50mm, if a continuous filament can be formed, this point is the gel point, and the time required from the melting of the powder coating to the gel point is called the gel time, and the unit of measurement is s express.

(4) Storage stability

Weigh 10g of powder, put it into an uncovered aluminum dish with a diameter of 50mm, and then place it at 40°C±3°C and a relative humidity of 95%±5%, check whether it is agglomerated after 48 hours, and measure the condensation. Glue time and tut-coating boilerplate. And compared with the original powder situation.

(5) Melting point

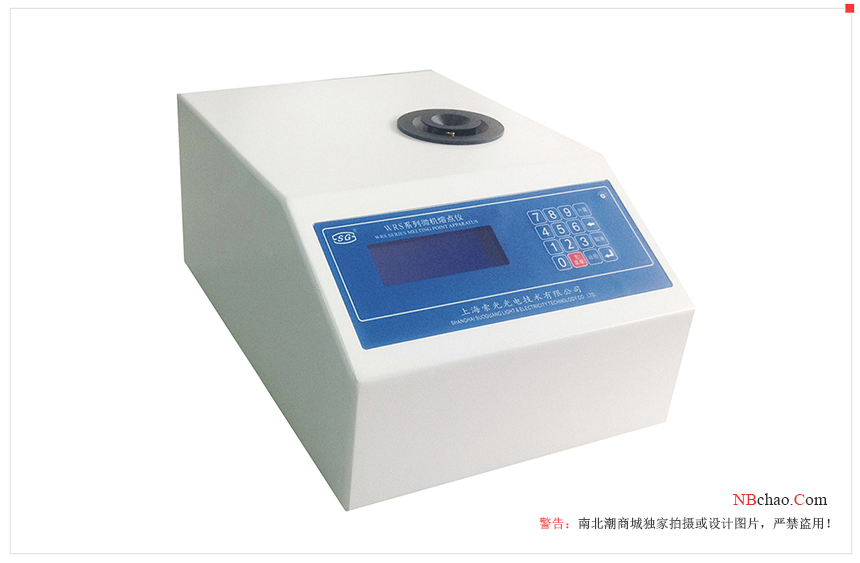

The melting point of powder coatings can be determined using a Kofler Hot Plate. It does this by distributing the powder over a narrow metal strip whose temperature varies uniformly from one end to the other. This enables accurate observation of the melting point range of the powder coating.

It is also possible to use a capillary to determine the melting point of powder coatings according to the general melting point determination method.

(6) Moisture content

The powder coating was dissolved in anhydrous dioxane. The trace moisture contained in the powder coating can be accurately measured by the Kari-Fischer moisture determination method.

(7) Density and relative density

①Apparent density is measured according to method A of ASTM D 1895.

②The volume factor shall be determined according to ASTM D 1895.

③The relative density shall be determined according to ASTM D 153 or as follows: a gallon weight cup may be used instead of a pycnometer. Due to the wide mouth of the measuring cup, it is easy to invert the powder without loss. In addition, it is easier to remove the incoming air by using a glass stirrer, and it is easier to wet it with gasoline (or other suitable carrier can be agreed between the buyer and the seller). Care must be taken to return the powder particles attached to the glass rod to the gallon weight cup to ensure the accuracy of the method.