Many metal adhesive joints in aviation have been used under high temperature conditions for a long time. With the development of aircraft at high altitude and high speed, the requirements for the use temperature of adhesives used at high temperatures are getting higher and higher, and the use time requirements are also getting higher and higher. long. For example, it is required to work for tens of thousands of hours at about 200 ℃ for large supersonic passenger aircraft .

The essence of studying the aging of adhesive joints at high temperature is to study the thermal aging resistance of adhesives. Since most adhesives are based on organic polymers, they have two different behaviors when heated. If the matrix is a thermoplastic resin adhesive, it will soften and melt when heated. If it is a thermosetting adhesive, it will only produce a large deformation under the action of heat. The above are their physical changes; in addition, they are under heat, oxygen and high temperature. Under the action of metallic iron, copper, cobalt and other element oxides, thermal decomposition and oxidative decomposition will occur, and a series of complex disproportionation, cyclization and crosslinking reactions will also occur during the decomposition reaction. Due to long-term heating, low molecular substances will escape from the adhesive layer, causing pores, causing the adhesive layer to become brittle, cracked, mechanical properties decreased, and even destroyed. In addition, for some incompletely cured adhesives, the strength increases due to further curing in the early stage of aging, but it will still decrease after a long period of high temperature.

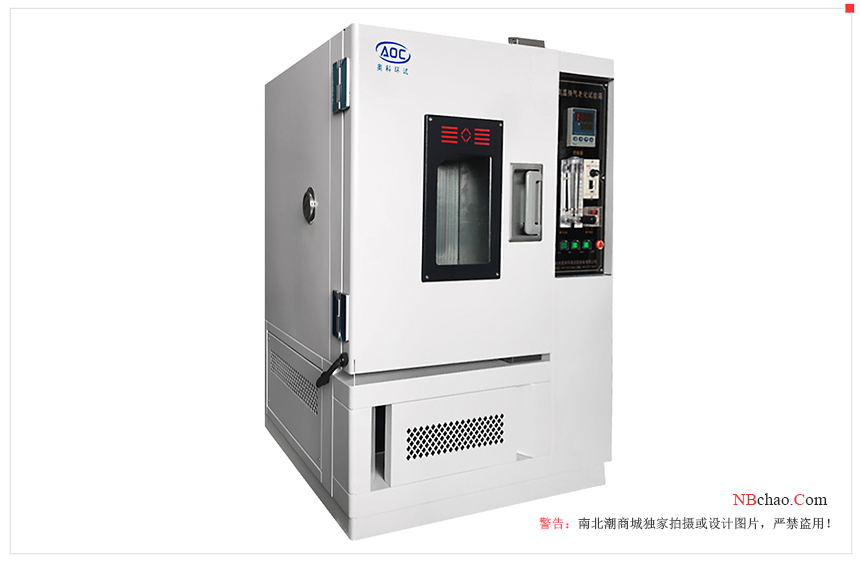

The aging Test Chamber used should comply with the corresponding national standards. The aging conditions are selected according to the performance and usage requirements of the adhesive: 80°C, 100°C, 120°C, 150°C, 180°C, 200°C, 250°C and 300°C... The aging time is 24h, 48h, 72h, 168h, 200h, 300h, 500h, 1000h, 3000h, 5000h, etc.

Samples are prepared according to the relevant technical documents or usage requirements provided by the adhesive manufacturer. The samples should be divided into two groups, one for measuring the data before aging and one for measuring the data after aging. When the samples are put into the aging box, each sample should be heated uniformly, and the temperature should be kept within the specified range of the test temperature. Time from the time when the sample is put in until the temperature stabilizes at the test temperature, and take it out at the specified time. After aging, the sample should be parked at the standard temperature of the laboratory (23±2)°C and relative humidity (50±5)% for 24 hours before testing the strength. Take the average value of a set of data, calculate the ratio of the strength after aging to the strength before aging, and multiply it by 100%, which is the strength retention rate after heat aging, also known as the aging coefficient.