It is defined as the resistance of coatings to tribomechanical action, and it is one of the important characteristics of those paint films that are often subjected to mechanical wear during use. Abrasion resistance is actually the embodiment of the comprehensive effect of hardness, adhesion and cohesion of the paint film, and is related to the type of substrate, surface treatment, temperature and humidity of the paint film during the drying process. Under other conditions being equal. The wear resistance of the coating is better than that of metal materials, because of the viscoelastic effect, which can buffer, absorb and release energy. At present, abrasive materials such as sand grains or grinding wheels are generally used to measure the wear resistance of the paint film . The following types are commonly used.

1. Shakeout method

The shakeout method is a simple method. That is to let sand particles of a certain size fall on the test plate from a specified height, and weigh the amount of sand required to destroy the paint film. The result is represented by the wear coefficient V/T. Where V is the volume of sand (L); T is the thickness of the coating (μm).

In the falling sand method, the paint film is not only worn by sand particles, but also impacted by sand particles, so the requirements for sand particles are relatively strict. Although this method is relatively old, the US ASTM is still used as a formal test standard to this day.

2. Jet method

The spraying method is mainly based on simulating the actual situation, such as the shot peening test of the automobile chassis, and the high temperature sand erosion test of the aero-engine. The sprayed abrasive can be quartz sand, iron shot, aluminum shot, etc., at a certain distance, with a fixed nozzle diameter, spray the abrasive on the coating through compressed air or carbon dioxide gas, and start to expose the metal substrate as the end point of the test . Sometimes hot compressed air at 150°C is used to spray preheated quartz sand for high temperature sand erosion test. American ASTM D658-81 stipulates the use of an abrasion Tester, the abrasive particle size is between 75 and 90 μm, and the wear resistance is expressed by the mass of abrasive required per unit thickness of abrasion.

3. Rubber grinding wheel method

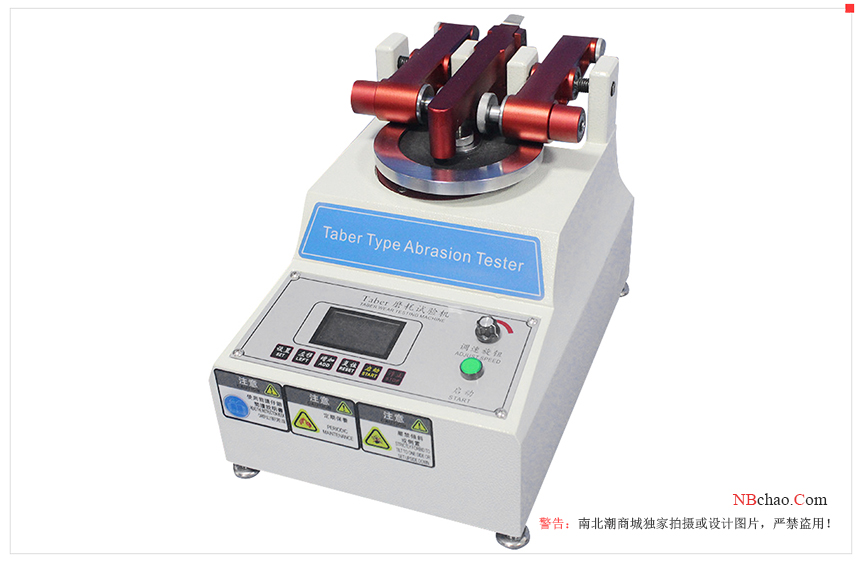

At present, the rubber grinding wheel method is usually carried out by Taber abrasion Tester in the world. The instrument has two rubber grinding wheels, one wears the sample from the center outward, and the other wears the sample from the outside to the center. Various loads can be applied to the wheel according to the test requirements, and the sample plate is fixed on the rotating disc under the wheel. The test can be done dry or wet, and the result is expressed by the number of grinding cycles required or the weight loss of the paint film after a certain number of grinding cycles.

The national standard "GB/T 1768-79 (89)" stipulates that the JM-1 paint film wear Tester is used, and after a certain number of grinding cycles, the paint film's weight loss is used to indicate its wear resistance. Because the weight loss method is not affected by the thickness of the paint film, with the same load and rotation speed, the smaller the weight loss, the better the wear resistance. This method is most suitable for road marking paints and floor paints that are mainly rubbed by heavy loads. There is a good relationship with the field wear results.