The defects of self-drying putty mainly refer to the defects of oily putty, ester glue putty, phenolic putty and alkyd putty.

1. Oily putty creates defects

Oily putty mainly refers to cooked tung oil gypsum powder putty, which is prone to defects such as poor scraping performance, slow drying, poor sanding performance, and bubbling during construction.

(1) Poor scraping property

It is mainly due to the poor scraping property caused by adding too much water during the deployment. Because plaster of paris powder is easy to absorb water and harden, if too much water is added, the putty will harden quickly after mixing, which will affect the scraping construction. Therefore, during the deployment, the amount of water added should be strictly controlled according to the product or formula, so as to prevent the putty from becoming hard and unable to be constructed, which will affect the construction progress. For the cooked tung oil putty that becomes hard and inconvenient for construction, appropriate amount of cooked tung oil and thinner should be added in time to mix well, and then scraped.

(2) slow drying

The main reason is that the amount of lead oil (thick paint) used in the deployment is too much. Therefore, the amount of lead oil should be strictly controlled to prevent it.

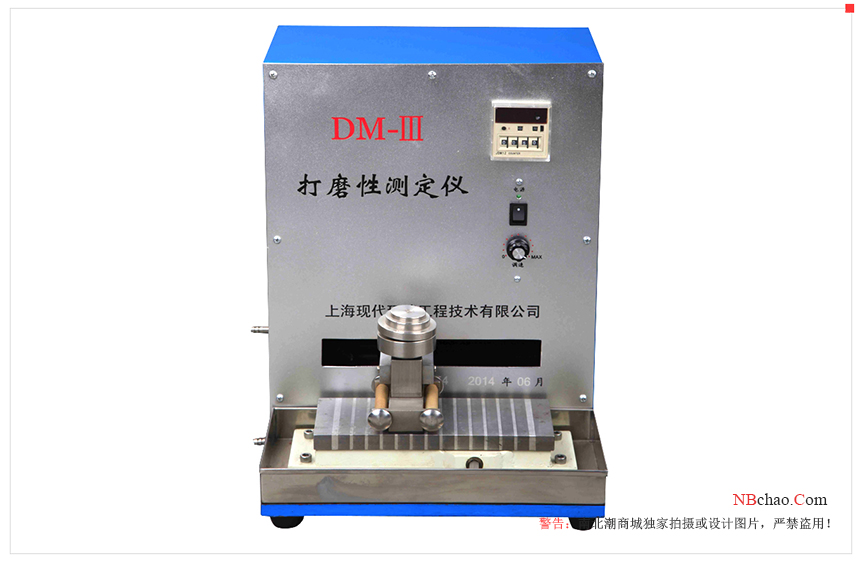

(3) poor grinding

When allocating, the add-on amount of cooked tung oil is too large and produces. Due to the high viscosity and strong adhesion of cooked tung oil, it is difficult to polish after drying. Therefore, when blending, the proportion of cooked tung oil should be appropriately reduced to prevent it from being difficult to polish after drying.

(4) bubbling

Cooked tung oil putty is usually self-drying. If baking is used for drying, the baking temperature should be controlled within the range of 60 ~ 70 ℃, and should not be too high. Otherwise, it is easy to produce bubbling and cause rework.

2. Defects caused by ester glue putty

Ester glue putty has better scraping property and fine quality, and each coat should not be scraped too thickly, otherwise it will easily cause slow drying defects and delay the construction period. Therefore, this putty is only suitable for filling the defects of thin putty, and cannot be used for filling and leveling with deep depressions to prevent slow drying.

3. Phenolic putty produces defects

Phenolic putty is usually divided into coarse putty and fine putty, which cannot be used wrongly during construction, such as coarse putty, which is suitable for filling pits, but not for defect filling, otherwise the surface is rough, which will affect the quality; while fine putty is suitable for thin layers Or fault filling, can not be used for pit filling, otherwise it will easily cause slow drying or long-term non-drying.

4. Alkyd putty creates defects

Alkyd putty is prone to defects such as poor scraping property, slow drying and bubbling during construction. The poor scraping property is the problem of putty itself. Because the scraping performance of this putty is not as good as that of ester glue putty and phenolic fine putty, it can only be used for local scraping during construction, and it is not suitable for large-area scraping of the whole car, in order to prevent defects such as curling due to poor scraping performance .

The drying of alkyd putty is too slow, mainly due to the one-time application and scraping too thick. In order to prevent this defect, the thickness of each layer of scraping should not exceed 1 mm; for the deep part of the depression, it should be constructed in multiple layers, and the front layer should be dried before scraping the back layer.

The bubbling defect of alkyd putty is mainly due to the bubbling caused by too thick coating and high temperature during baking. Solution: First, the baking and drying should not be too thick; second, the baking temperature should not be higher than 100°C.