Surface tension is one of two key factors (the other is surface energy) for proper wetting of a substrate. The tension causes the liquid to move into a spherical shape, just as the liquid is surrounded by an elastic membrane under tension. These molecules want to stick to each other instead of breaking apart in mid-air. It also prevents small particles from sinking into the liquid.

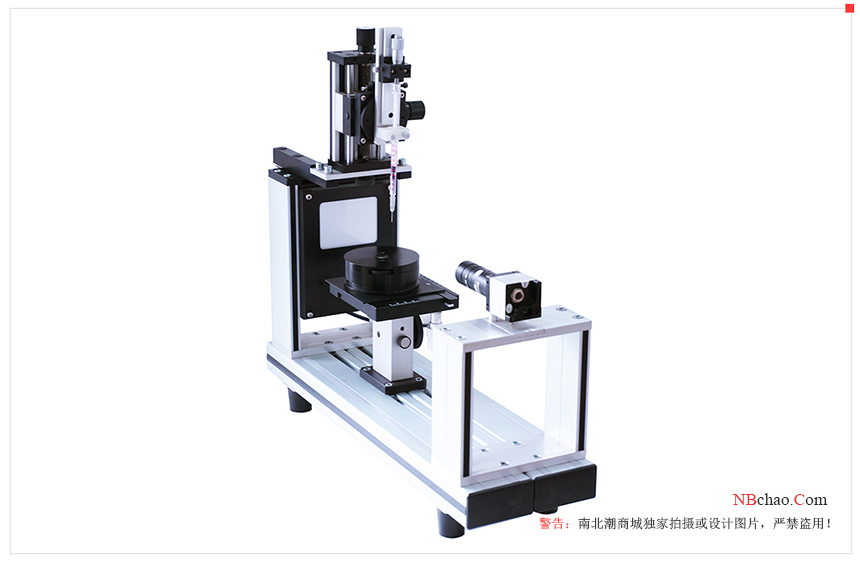

In flexographic printing, surface tension affects the correct application of ink to the substrate. Fortunately, surface tension can be measured using a surface tension test ink.

This ensures the surface is ready for printing and provides quality assurance control during the printing process.

Everything you need to know about surface tension testing inks, including their limitations:

How do surface tension test inks work?

Still not sure how to measure surface tension? First, since the purpose of flexographic surface tension testing is to determine surface wettability, it is known that the test inks have a variety of surface tensions. This is a good thing, as surface wetting can be quite a challenge.

After pretreatment, the Tester uses a brush to quickly apply the high voltage test ink to the surface. The surface was considered wettable if the edge of the brushstroke remained steady for 2 seconds.

If the ink appears in drops rather than even strokes, the Tester will continue to move to the next lower level of test ink until the surface tension is at least equal to that of the test ink.

Which materials are used as surface tension test inks?

Depending on the surface to be inspected, several types of inks can be used for wetting tension testing.

Alcohol Test Inks: These inks are suitable for most common surfaces.

Formamide Test Inks: Can be used on hotter surfaces, but not PVC. Extra care is required as these inks are toxic and require longer reading times to correctly identify the results.

Methanol Test Inks: Again, these inks will work on most common surfaces, but these inks are also toxic so extra care is required.

As a press operator, you probably don't want to invest in new test inks - and you probably don't have to! To make things easier, you can follow the same steps above, but use your own print-ready ink.

The Importance of Surface Tension in Flexographic Printing

The most important thing in printing is to ensure that the ink soaks evenly on the substrate. Due to the increasing use of water-based inks and different types of substrates, more flexographic printing presses use this simple surface tension measurement, so the process can be adjusted accordingly.

Failure to employ these techniques can result in:

lack of adhesive properties

poor print quality

production interruption

dissatisfied customer

Possible Limitations of Ink Testing

These measurements are relative and there may only be perceptible differences in surface tension from one surface tension to the next.

This test measures the surface tension/wettability of a specific sample of a substrate in a given environment at only one specific point in time. The test material needs to be exactly the same as the material used in the printing process. As testing continues, the properties of the substrate itself may change due to environmental factors.

Any delay between surface wettability testing and printing can lead to variable results. It cannot be overstated how important industry experience and a critical thinking process are to successfully using ink testing.