How do you know which industrial pH sensor is a good choice for your application? The number of industrial combination pH sensors varies. Before purchasing an industrial pH sensor, it cannot be overstated the importance of better understanding your application and the conditions the sensor will be subjected to during use. Based on this knowledge, you can decide what types of functionality you need. Here are some questions you might want to consider:

What is the required cable length?

This is considered the distance between the sensor and the front end of the equipment such as a controller, analyzer or transmitter. If the cable length is greater than 25 feet or 8 meters, it may be necessary to install a preamplifier between the sensor and the controller. A preamplifier converts the high-impedance millivolt signal of a pH or ORP sensor, which can travel to a thousand feet of lower-impedance signal.

How will the sensor be installed?

It is important to understand how the sensor is installed. Two common installation methods for industrial pH sensors are: in-line (flow cell/tee) or submerged (tank or vessel). Depending on the method of installation, different pH sensor types and accessories may be available for your application. For example, if you need an in-line pH sensor, a flat surface design may be suitable for your application, since the flow through the sensor acts as a self-cleaning mechanism, extending the life of the probe.

Is Automatic Temperature Compensation (ATC) required?

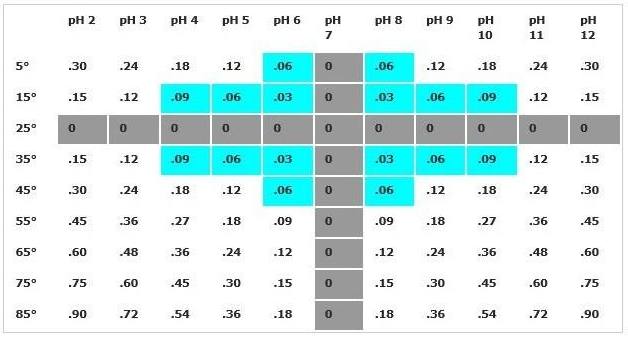

pH measurement is temperature dependent. If your process application requires an extreme and varying temperature range, pH measurement will most likely require temperature compensation. When determining whether automatic temperature compensation (ATC) is required, the required pH accuracy, process temperature range, and pH measurement range should be considered. The following table is helpful in making this determination:

Temperature Error Graph

Note: The numerical error of light blue is less than 0.1, temperature compensation may not be needed. In gray temperature and pH, there is no error in temperature to pH.

What type of instrument will be used with the pH sensor?

Need to know if you are connecting an industrial pH sensor to a controller, transmitter, analyzer, PLC, DCS system, data logger, PC or any other device. This is important because you want to know what type of output signal your sensor requires and whether it is compatible with the instrument you want to use it with. If temperature compensation is enabled, it is also important to match the temperature element (i.e. RTD, thermistor, etc.) embedded in the pH sensor to the temperature requirements of the front end of the device. Sensorex pH sensors are compatible with most standard pH transmitters/controllers on the market. Sensorex also offers a range of pH transmitters and controllers.

What can challenge pH electrodes in water treatment?

For example:

What is the maximum temperature of the water?

Extremely high temperatures can damage the material of the pH sensor.

Are you measuring pure water or is hydrofluoric acid present in the process?

Standard pH sensors cannot operate in these types of environments for long periods of time and will result in inaccurate pH measurements. For these process environments, Sensorex offers specially designed versions of our industrial pH sensors for applications with low conductivity (-LC) or where hydrofluoric acid (-HF) is present.

Are there any known ground loop issues?

For process pH sensors, ground loops are unwanted current paths in systems where stray signals can interfere with pH measurements. If this is a recognized problem, a pH sensor with a solution grounded electrode will need to be used to deal with stray voltages in the process system.