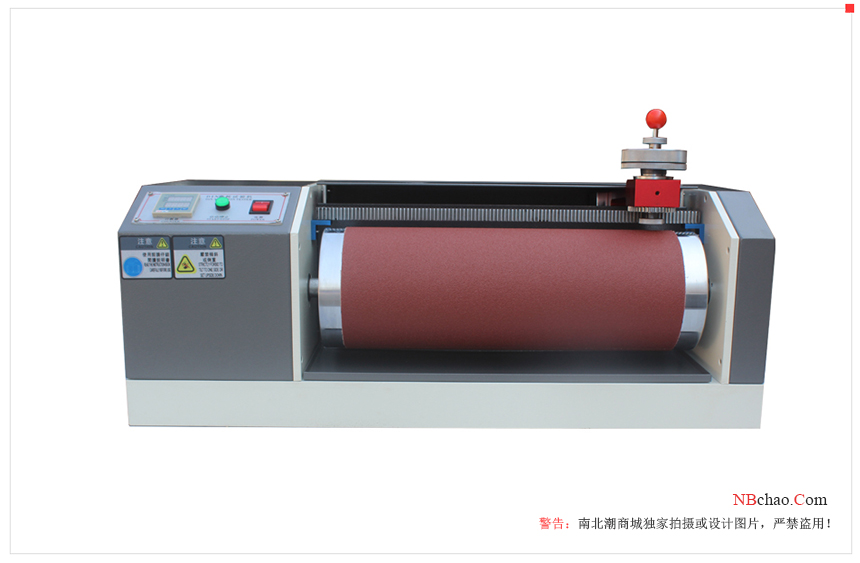

Wear is the main factor that seriously affects the surface quality of materials. Wear testing on materials helps to compare the quality of coating materials by providing real-time conditions and predict the actual life of the product. Abrasion tests are performed on coated or plated materials to check the wear resistance of the material. With the help of this test different materials such as composites, metals, ceramics, thick coatings such as thermal spraying, etc. can be tested. The core function of this test is to generate data to help measure a material's grade or grade based on its abrasion and scratch resistance qualities under specific conditions. The test is performed using an abrasion Tester.

This test has never been used to analyze a material's electrical resistance in a specific type of environment. Its value lies in the determination of material grades in order of quality and occurs in relatively highly abrasive environments. The actual amount of loss in the data obtained from this test under the specific conditions of the abrasive environment is then compared to test samples that the manufacturer has examined under the same environmental conditions. This test comparison helps the manufacturer to clearly indicate the actual value and life of the material and other factors that may reduce the quality of the material.

Standardized method used by professionals for wear testing

Different types of abrasion tests are carried out in different industries to test the abrasion resistance of materials. Abrasion testing is performed on paint and plating, rubber, printing and more. This test helps to check the actual loss of material when providing a highly abrasive environment. A number of standards have been introduced by various national and international standardization bodies to test the quality of different materials such as ASTM G65 – Testing Wear Using Dry Rubber Wheel Equipment; ASTM G132 – Performing Pin Wear Tests and many more.

Abrasion Test Standard

IS 3400 (Part 3) – 2012: Test Methods for Vulcanized Rubber Part 3: Abrasion

ASTM F1978 – Abrasion Resistance of Laminates

ASTM D3794 – Standard Guide for Testing Coil Coatings

ASTM D3363 – Standard Test Method for Pencil Test Film Hardness – Rapid Determination of Hardness of Organic Coatings

ASTM D6279 – Test Method for Mar Resistance of High Gloss Coatings – Wet and Dry Abrasion Resistance Tests

For detailed information about the wear test, please consult the customer service of Beichao Mall.